We all want our homes and our workplaces to be warm and cosy, but not at the cost of catastrophic climate change. That’s why decarbonising our heating is a challenge that simply cannot be ignored.

Making decisions about how this is done requires careful consideration and a detailed, deliverable national strategy.

Here we discuss the key issues in decarbonising heat.

The numbers

The Climate Change Act commits the UK to reducing its carbon emissions by at least 80 per cent of their 1990 levels by 2050.

As heating our homes and workplaces is responsible for almost one fifth of our country’s total carbon emissions, we are clearly going to need to make huge changes to the way we keep our homes and workplaces warm in order to meet those commitments.

‘Over 80% of energy used in homes is for heating – suggesting large potential for continued decarbonisation.’

— Energising Britain: Progress, impacts and outlook for transforming Britain’s energy system, by I. Staffell, M. Jansen, A. Chase, C. Lewis and E. Cotton, 2018.

Improved insulation, greater energy efficiency and electrification will all reduce the need for fossil fuel-based heating. However, domestic energy efficiency in the UK is lagging well behind targets, although the situation varies from region to region – and such targets do not even exist yet for the non-domestic sector.

Roof insulation material

Even in a low or zero-carbon future, we’re still going to need to keep our homes and workplaces warm – and affordably.

Future policy

Against this backdrop, in March 2018, the UK Government issued a call for evidence for a Future Framework for Heat in Buildings.

Chancellor Phillip Hammond introduced a new ‘future homes standard’ in his 2019 Spring Budget Statement, “mandating the end of fossil fuel heating systems.” Gas boilers will be banned from all new homes from 2025.

A major change is coming. But what else will we need to change in order to transform our heating systems?

1. More electrification

The most noticeable change in the way we heat our homes and workspaces in the future may well come from the need to switch from systems that fuelled by natural gas to ones that are driven by electricity.

Some technologies that can offer a solution to the challenge of decarbonising heating depend on a significant amount of electricity to keep the warmth flowing.

For instance, the hybrid heat pump scenario which is currently supported by the Committee on Climate Change would see up to 85% of a consumer’s need for heat being met by low-carbon electricity.

To give some context to that figure, according to the Committee, 85 per cent of the UK’s homes now rely on fossil-fuel derived natural gas for heating and hot water, and on average these: “currently emit around 2tCO2 per household per year… which represents around one tenth of the average UK household’s carbon footprint.”

Changing from a situation where our heating depends on 85% fossil fuel gas to one that depends on 85% low or zero carbon electricity is little short of a complete transformation. Given that the new future homes standard is due to be introduced in less than six years, this transformation will need to happen quickly.

Of course, a great deal of the extra electricity needed will come from intermittent renewables such as wind turbines and solar panels – especially as the cost of renewable electricity is falling.

Much of that power looks likely to be supplied by distributed sources rather than those integrated into the national grid. Indeed, since 2011, power generation capacity connected directly to the distribution network grew from 12 gigawatts (GW) to more than 40 GW by the end of 2017, according to estimates from energy experts Cornwall Insight in a report for our B2B energy supply business, Haven Power.

With so much of our electricity reliant on the weather, there will still be a need for dispatchable and flexible thermal sources and energy storage, such as Drax and Cruachan power stations. Their centralised power generation can be turned up and fed directly into the national transmission system at short notice, to keep our heating running and our homes warm.

Dam and reservoir, Cruachan Power Station, Scotland

Such a transformation will obviously require careful strategic planning as well as an enormous amount of investment.

There may well be no single solution to the challenge of heat decarbonisation, rather a number of different solutions that depend on where people live and work, their individual circumstances, the energy efficiency of their homes and the resources they have close at hand.

But while it has previously been reported that the overall or system costs of electrifying heating could be as much as three times the cost of using gas, another study suggests that the costs could be much closer.

2. More heat pumps

Heat pumps that absorb environmental warmth and use it to provide low carbon heating have always been considered a possible option for the four million homes and countless workplaces that are not currently connected to the UK’s mains gas network.

Recently expert opinion has been changing with hybrid heat pumps seen as a workable solution even for homes and workplaces that are connected to gas supplies. Indeed, in 2018 the Committee on Climate Change stated that hybrid heat pumps: “can be the lowest cost option where homes are sufficiently insulated, or can be insulated affordably.” This means that they may be one of the simplest and most affordable options to provide the heating of the future.

Hybrid heat pumps draw heat from the air or ground around them and use a boiler to provide extra heat when the weather is exceptionally cold. In a low carbon future, that boiler could be fuelled by biogas. In a zero carbon situation, it could be powered by hydrogen.

Heat pumps can be air-source (ASHP) – absorbing warmth from the atmosphere like the heat exchanger in your fridge in reverse – or ground source (GSHP). GSHPs absorb heat through on a network of pipes (a ground loop) buried or a vertical borehole drilled in the earth outside your home or workplace.

Both ASHPs and GSHPs can be used to support underfloor heating or a radiator system, though neither will provide water heated to the high temperature a natural gas boiler will reach to keep radiators hot.

And even though the warmth they absorb is free, heat pumps depend on a supply of electricity to condense it and to bring it back to the heating system inside the house.

This electricity could be generated by distributed power from local solar PV, wind turbines, drawn from batteries or even from the low carbon grid of the future.

It is worth noting that the size of heat pumps and the amount of land they require – especially GSHP – makes them a less attractive solution for people who live or work in built up areas such as cities. While for those who live in blocks of flats, it is difficult to see how individual heat pumps could be a practical solution.

3. More hydrogen

The idea of switching the mains gas grid to store and transport hydrogen has long appealed as a potential solution to the challenge of decarbonising heating. Renewable hydrogen could then be burnt in domestic boilers similar to those we currently use for natural gas.

The benefits are many. Hydrogen produces no carbon emissions when burnt, and can be stored and transported in much the same way as natural gas (provided old metal pipes have been replaced with modern alternatives).

And given the sunk costs involved in the existing gas grid and in the network of pipes and radiators already installed in tens of millions of homes, hydrogen has always been expected to be the lowest cost option too.

However, according to the Committee on Climate Change’s latest findings, hydrogen should not be seen as a ‘silver bullet’ solution, capable of transforming our entire heating landscape in a single change.

The main reasons they give for this judgment are the relatively high cost of the electricity required to produce sufficient hydrogen to power tens of millions of boilers, the undesirability of relying on substantial imports of hydrogen, and the lack of a carbon-free method to supply the gas cost-effectively at scale.

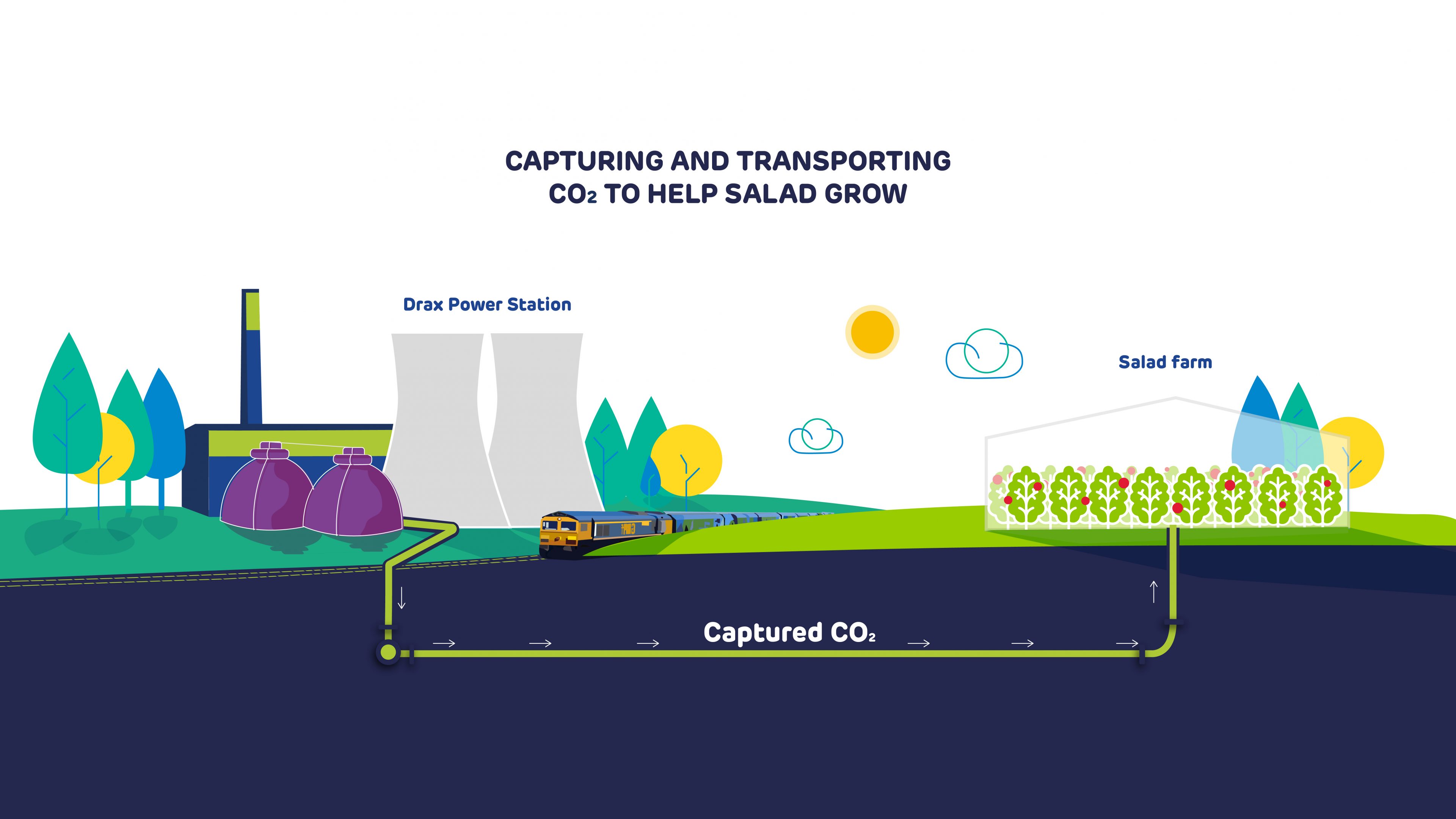

Hydrogen could, however, be produced by gas reformation of the emissions retained by bioenergy carbon capture and storage (BECCS) such as that being pioneered at Drax Power Station. Carbon capture use and storage (CCUS), of which BECCS is the renewable variant, is supported by the UK government through its Clean Growth Strategy as it has potential to accelerate decarbonisation in power and industrial sectors.

Extremely rapid progress to provide hydrogen in sufficient quantities from BECCS is unlikely – but the first schemes could begin operating in the late 2020s.

Hydrogen production also has the potential to radically transform the economics of CCUS, making it a much more attractive investment.

It was originally assumed that the power required to drive the energy-intensive process of hydrogen created via electrolysis would come from surplus electricity generated by intermittent renewables at times of low demand. However, that surplus is not now generally regarded as likely to be sufficiently large to be relied upon.

It is these limitations, together with a comprehensive model of the likely costs involved in different approaches to decarbonisation, that led the Committee on Climate Change to suggest that hybrid heat pumps could provide the bulk of domestic heating in the future.

At present, it seems likely that converting to hydrogen-fuelled boilers will mainly be an attractive option for those who live and work near areas where the renewable fuel can be most easily created and stored. The north of England is a prime example – close to the energy and carbon intensive areas of the Humber and Tees valleys where CCUS and hydrogen clusters could be located with good access to North Sea carbon stores such as aquifers and former gas fields.

4. More solar

Many homes in the UK – especially in the south – could be heated electrically without carbon emissions at the point of use.

Solar thermal (for water heating) or solar PVs (for electric and water heating) common sights on domestic property rooftops. The intermittency of solar power need not be an issue as the electricity generated could then be stored in batteries ‘behind the meter’ until it is needed.

However, the lack of sufficient daylight for much of the year in many parts of the UK could, together with the still relatively high cost of battery storage, still mean that this would not necessarily be a solution that can be applied at scale to millions of homes and workplaces all year round.

As the cost of battery storage continues to fall, it may well be that solar becomes a more practical and cost-effective solution.

5. More biomass

More geothermal

Sustainably sourced compressed wood pellets and biomass boilers have long been proposed as a potential solution to decarbonising heating for the many people who live and work off the mains gas grid. Bioenergy as a whole – including biogas as well as wood pellets – now provides around four percent of UK heat, up from 1.4% in 2008.

The main barriers to this are the current relatively high cost of biomass boilers. This is currently offset by the Renewable Heating Incentive (RHI) which the UK government has committed to continuing until 2021.

As this solution is adopted by more consumers, it is anticipated that the real costs of such new technology will fall as economies of scale start to take effect in much the same way that solar PV and battery technology has recently become more affordable.

6. More geothermal

Ruins of a tin mine, Wheal Coates Mine, St. Agnes, Cornwall, England

Geothermal energy uses the heat stored beneath the surface of our planet itself to provide the energy we need.

While in some countries such as Iceland, geothermal energy is used to drive turbines to generate electricity that is then used to provide power for heating, it is envisaged that in the UK it could be converted into warmth through massive heat pumps that provide heating to entire communities – especially those in former mining areas. There is already one geothermal district heating scheme in operation in the UK, in Southampton.

It is envisaged that such geothermal schemes would work most effectively at a district level, providing zero carbon heat to many homes and workplaces. According to a recent report, geothermal energy has the potential to “produce up to 20 per cent of UK electricity and heat for millions.”

At present, drilling is being carried out to see if geothermal heating could be viable in Cornwall. However, there is no reason why it could not be used in disused coalmines too where ground source heat pumps (GSHPs) would absorb and condense the required heat. This means that geothermal could have strong potential as a solution to the challenge of decarbonisation for former mining communities.

7. More CHP

By using the heat created in thermal renewable electricity generation – such as biomass – in combined heat and power schemes, businesses and individuals can reduce their energy costs and their carbon emissions. Such schemes can work well for new developments on a district basis, and are already popular in mainland Europe, especially Sweden, Denmark and Switzerland.

Warm homes, factories and offices

There are already a number of viable solutions to decarbonising heating in the UK. They rely on smart policy, smarter technology and customers taking control of their energy.

Rather than any one of these technologies providing a single solution that can help every consumer and business in the country to meet the challenge in the same way, it is more likely that it will be met by a number of different solutions, depending on geography, cost and individual circumstances. These will sometimes also work in concert rather than alone.

The UK has made solid progress on reducing carbon emissions – especially in power generation. When it comes to heating buildings, rapid decarbonisation is now needed. And that decarbonisation must avoid fuel poverty and help to rebalance the economy.

Find out more about energy in buildings in Energising Britain: Progress, impacts and outlook for transforming Britain’s energy system.

Quarter after quarter, the carbon intensity of Great Britain’s electricity system has declined. From 545 grams of carbon dioxide (CO2) per kilowatt hour (g/kWh) in Q1 2012, to just over 200 g/kWh last quarter. For a single hour, carbon emissions have fallen as low as just 56 g/kWh. But how soon can that figure reach all the way down to net-zero carbon emissions?

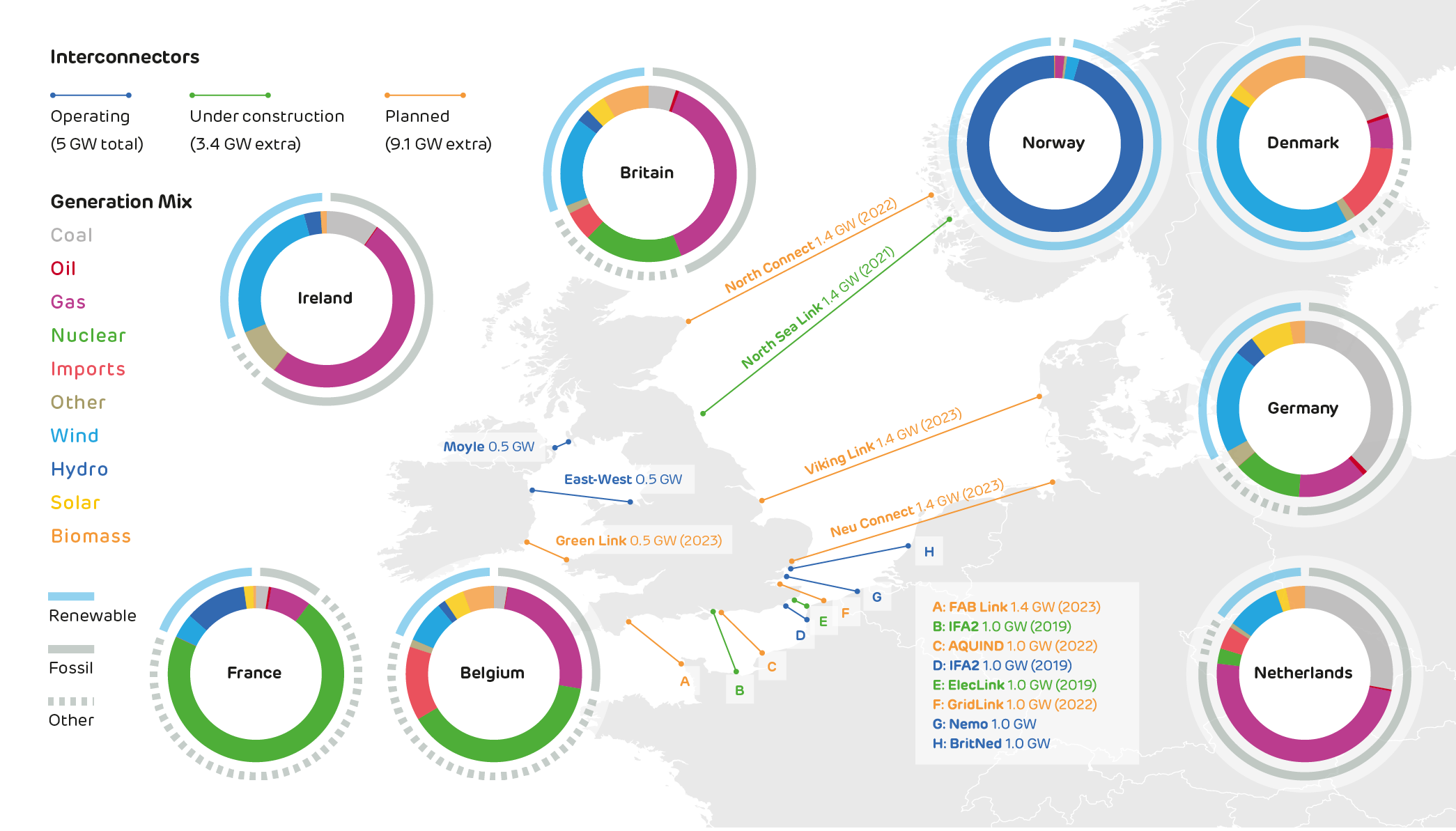

Quarter after quarter, the carbon intensity of Great Britain’s electricity system has declined. From 545 grams of carbon dioxide (CO2) per kilowatt hour (g/kWh) in Q1 2012, to just over 200 g/kWh last quarter. For a single hour, carbon emissions have fallen as low as just 56 g/kWh. But how soon can that figure reach all the way down to net-zero carbon emissions? Great Britain added a new power source to its electricity system in Q1 2019, in the form of Belgium. The opening of the £600 million NEMO link between Kent and Zeebrugge added another 1 GW of interconnection capacity.

Great Britain added a new power source to its electricity system in Q1 2019, in the form of Belgium. The opening of the £600 million NEMO link between Kent and Zeebrugge added another 1 GW of interconnection capacity.

Burning waste and growing algae

Burning waste and growing algae Fully integrating BECCS into biomass power

Fully integrating BECCS into biomass power