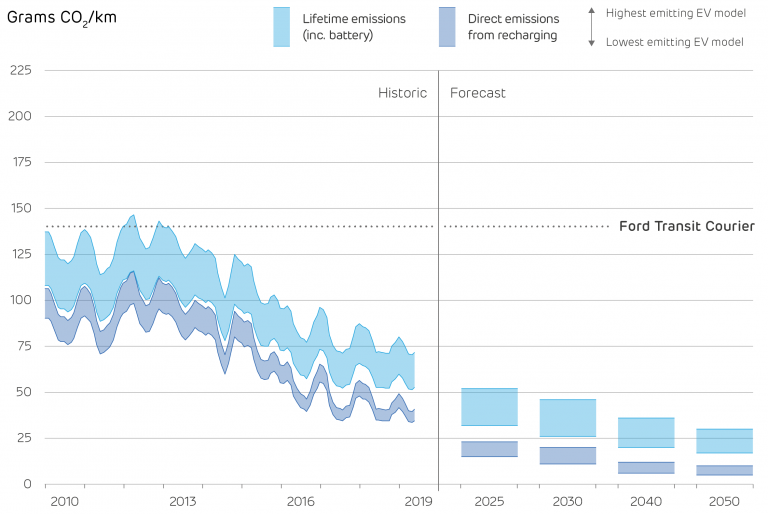

The future of electric cars and electric vans holds great potential – not just for the transport industry’s overall carbon footprint, but for the populations of heavily congested, polluted cities and even individual drivers looking for more efficient fuel costs.

That future is approaching fast. By 2040 or even as soon as 2035 no new cars or vans sold in the UK can be solely powered by diesel or petrol. While this is a positive step, it brings with it a shift in the way drivers will need to manage the way they plan journeys and, more importantly, refuel.

For years drivers have relied on a quick and plentiful supply of fuel at petrol stations. But an EV doesn’t charge as quickly as a conventional car, nor are fast charging points widespread – at least not right now.

The change will be considerable, but it won’t necessarily take shape in a single form. Here we look at four things that will become increasingly influential in how drivers recharge their EVs over the coming years.

-

Smart charging and time-of-use tariffs

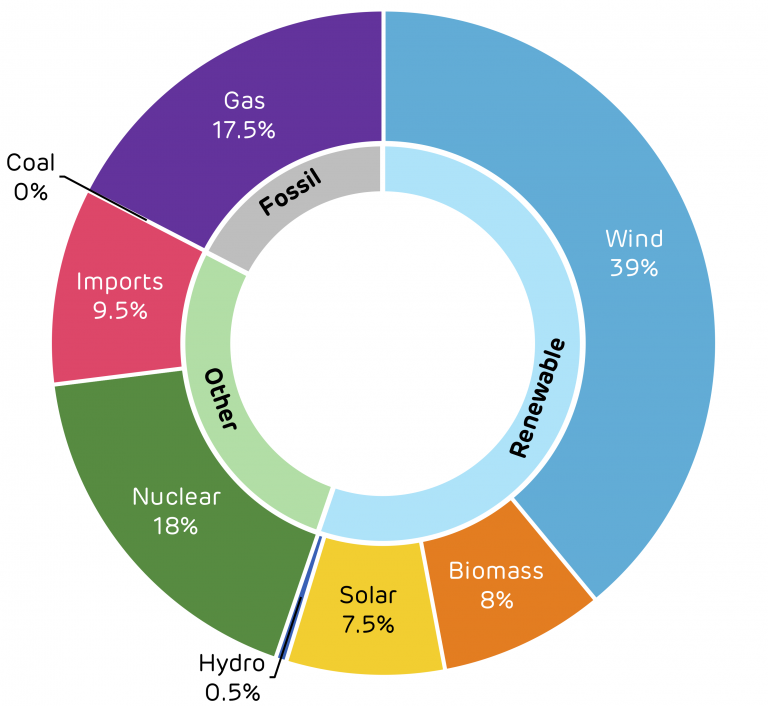

Electricity costs more to produce and supply at certain times of the day. This wholesale price depends on the demand for power, weather conditions and the costs of different generation technologies and fuels.

For example, electricity is often more expensive in the evenings when people are coming home from work and turning on lights, TVs, ovens and plugging in devices. Just a few hours later it rapidly drops in price as homes and offices turn off lights and appliances. But the power system is changing.

The price of electricity is increasingly driven by less predictable factors such as the weather. On windy and sunny days, wind and solar generation can drive down the cost of producing power. On calm and cloudy days, the costs of electricity can increase.

While this, in theory, makes it sensible to wait for a cheap period of time to plug in and charge an electric vehicle (EV), in practice people are unlikely to spend the time sit refreshing websites which display the price of electricity in real time to get the best value. Instead, the use of ‘smart charging technology’ can play a big role to capitalise on fluctuations in prices.

Smart charging technology will be able to monitor things like electricity prices and even electricity usage across an entire site (for example across a business where many devices are using electricity) and automate the charging process to make use of the best prices and limit overall electricity use.

Rather than needing someone to recharge EVs at one o’clock in the morning, this means people or businesses can plug in at times convenient to them and set their vehicles to charge at the cheapest times and have an appropriate amount of charge to carry out tasks when they need to.

“By shifting power usage into cheaper periods you’re saving money and you can be more sympathetic to supply and demand limits on a company,” explains Adam Hall, who leads Drax’s EV proposition. “If I know my battery will be fully charged by nine in the morning, do I care if it charges immediately or delays it and saves me a few pounds?” For business fleet owners who manage large numbers of electric vehicles the difference this can make is even larger, he adds.

-

Vehicle-to-grid (V2G) technology

Each EV has a battery in it that powers the vehicle’s motor. But what if the electricity stored in that battery could also be harnessed to deliver electricity back to grid? And what if that concept could be used to collect a small portion of power from every idle EV in the country and use it to plug gaps in the electricity system?

“There are over 30 million cars on UK roads. National Grid predicts by 2050, 99% of those vehicles will be powered by electricity,” explains Hall. “The majority of cars remain idle for 95% of any day. That’s a huge amount of storage potential that could be used to balance the grid at key times. It’s a battery network that assets around the country will be able to use.”

This concept is what’s called vehicle to grid technology (V2G), and while it holds great potential, it’s still some way from becoming a mainstream source of reserve power. Right now the technology is costly and limited – only ‘CHAdeMO’ charging systems, as found on Japanese models, actually support bi-directional charging. Nevertheless, Hall remains optimistic of its future role in the energy system, particularly as this technology will be hugely important in managing future grid constraints

“The cost of bi-directional hardware is coming down all the time,” he says. “At the moment there aren’t enough vehicles, we don’t have the scale to do it, but I fully believe it will change quite dramatically.”

For domestic users the benefit will be less immediate than it will be for entire countries. For business fleet managers, allowing the grid to take some power from their idle vehicles could lead to financial compensation or other advantages for offering grid support.

-

The out of sight, out of mind approach: third party management schemes

More suited for businesses managing whole fleets of vehicles, employing a third party to manage the charging of vehicles allows for the delegation of a potentially costly and time-consuming task.

Adam Hall, Drax EV proposition lead, with Drax’s electric vehicle fleet service.

“Effectively the customer knows they’ll get the vehicles with the amount of charge they want when they need it,” says Hall. “That might be for the cheapest price or as fast as possible. It means the customer doesn’t have to think, they just get their charged vehicle in the optimum way for their needs.”

Third party providers could also open up new charging businesses models, such as flat monthly rates for unlimited vehicle charging or all-renewable services. By taking the technical aspects of running a fleet out of businesses hands, third parties could even serve to lower the barrier to EV adoption.

-

Mandatory managed charging

It’s difficult to accurately know how much demand electric vehicles will place on the electricity system– some estimates see demand growing in Great Britain as much as 22% by 2050 as a result of EVs.

While the constant development of battery and charging technology will likely mean this prediction will come down, there are some theories as to how the country will need to deal with this rapid growth. One of these is to actually turn down the electricity surging through charging points at certain points to prevent widespread blackouts.

While the constant development of battery and charging technology will likely mean this prediction will come down, there are some theories as to how the country will need to deal with this rapid growth. One of these is to actually turn down the electricity surging through charging points at certain points to prevent widespread blackouts.

“The idea is there to protect the grid,” explains Hall. “When local distribution networks have a lot of demand they may need to turn charge points down.” He adds there will likely be exemptions for emergency services, however.

Hall is sceptical mandatory managed charging would ever really come into play, for the damage it would do to consumer attitudes to EVs. The idea also taps into wider scaremongering around EVs and quite how much they will push up electricity demand.

Instead what will really need to shift for a future of efficiently charged vehicles is a mindset shift. “There’s a psychological element to it,” he suggests. “Everyone goes through some range anxiety at first but soon realises the technology is sound.”

As battery technology continues to improve, vehicles evolve to go further on a single charge, and networks of super-fast charge points expand, transitioning to electric vehicles will become easier and more economical for businesses than continuing to depend on fossil fuel.

“I personally believe once electric vehicles are doing 300 miles on a single charge, the requirement for on-route charging will be pretty low,” says Hall. “Not many people drive 300 miles, need to recharge at a service station and then drive anther 300 in one fell swoop. It’s much more important to have good charging installations at work and at home.”

There are many ways in which EVs will change the way the world drives, from how we charge them to how and where we travel. We can be certain this will mean a shift in mindsets and our approach to transport. What remains uncertain is just how quickly and widespread that shift will be.

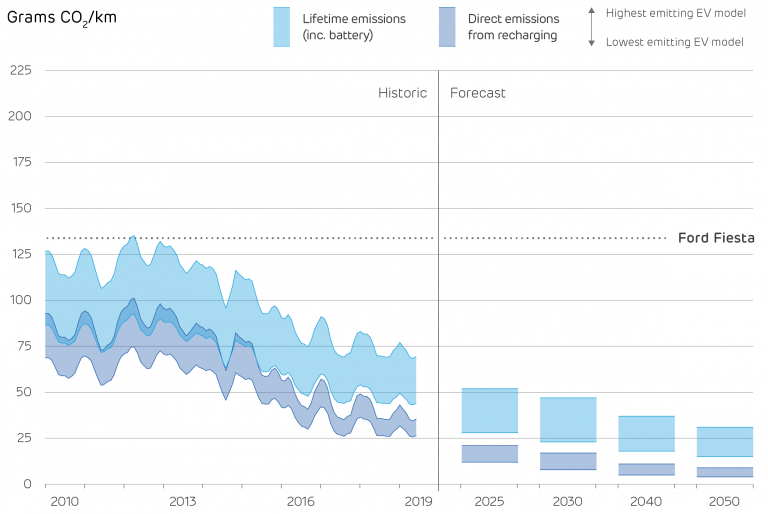

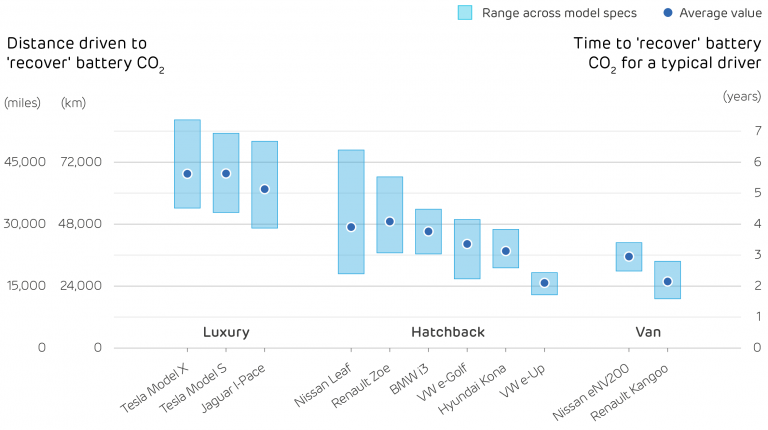

EV models: Nissan Leaf, Renault Zoe, Volkswagen e-Golf and e-Up, Hyundai Kona and BMW i3

EV models: Nissan Leaf, Renault Zoe, Volkswagen e-Golf and e-Up, Hyundai Kona and BMW i3

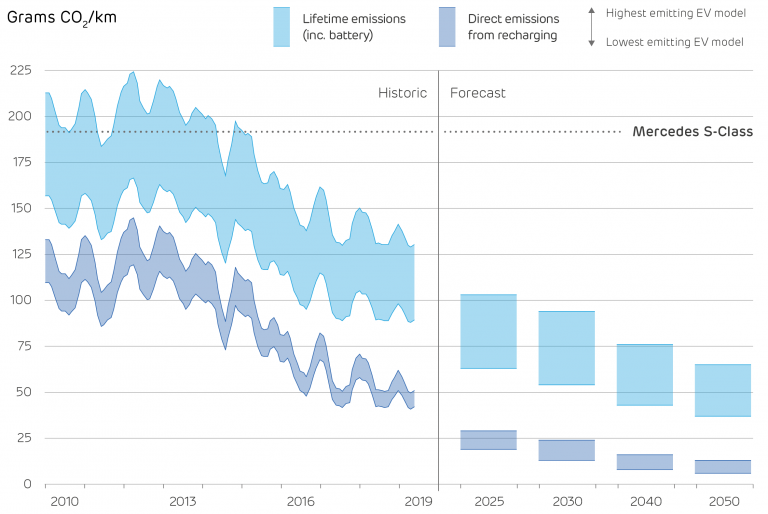

Models considered: Jaguar i-Pace, Tesla Model S and Model X

Models considered: Jaguar i-Pace, Tesla Model S and Model X

Models considered: Nissan e-NV200 and Renault Kangoo

Models considered: Nissan e-NV200 and Renault Kangoo

Aeroplanes still rely on fossil fuels to provide the huge amount of power needed for take-off. Globally flights produced

Aeroplanes still rely on fossil fuels to provide the huge amount of power needed for take-off. Globally flights produced