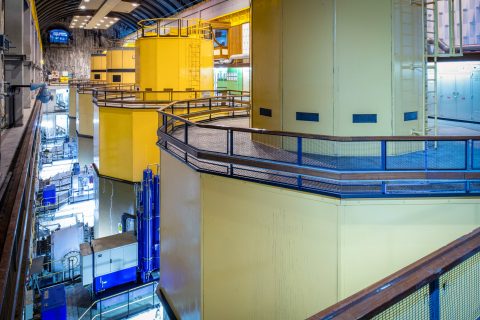

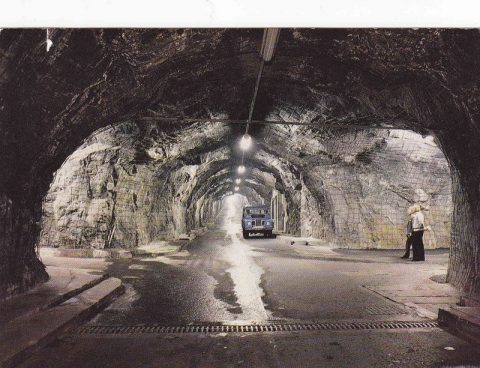

Down the kilometre-long tunnel that burrows into the dark rock of Ben Cruachan, above the giant rumbling turbines, sits something unusual for a power station: a work of art.

The wood and gold-leaf mural might seem at odds with the yellow metal turbines, granite cavern walls, and noise and heat around it, but it’s closely connected to the power station and its ties to the surrounding landscape.

The entrance tunnel might take engineers and machines to the heart of Ben Cruachan, but the mural transports viewers to the mountain’s mythical past. It tells the story of how this remarkable engineering achievement came to help power the country.

The narrative of the mural

Much like the machines and physical environment surrounding it, the Cruachan mural is big, measuring 14.6 metres long by 3.6 metres tall. Combining wood, plastic and gold leaf, the relief is interspersed with Celtic crosses, textures evocative of granite rock and gold orbs that resemble the urban lights Cruachan helps to power. Running from left to right, it tells a linear narrative that spans the history of the mountain.

An artist’s impression of the mural in the Visitor Centre at Cruachan

In the first of the mural’s three segments is a Scottish red deer, a native species that still thrives in Scotland today. Below it is the figure of the Cailleach Bheur, a legendary old woman or hag found across Gaelic mythology in Scotland, Ireland and on the Isle of Man. The Cailleach has a symbolic representation of a variety of roles in different folklores, but she commonly appears as a personification of winter, and with that, as a source of destruction.

In the context of Ben Cruachan, Cailleach Bheur is often taken to mean the ‘Old Hag of The Ridges,’ a figure who acts as the mythical guardian of a spring on the mountain’s peak. The mural tells her story, of how she was tasked to cover the well with a slab of stone at sundown and lift it away at sunrise. One evening, however, she fell asleep and failed to cover the well, allowing it to overflow and cause water to cascade down the mountain, flooding the valley below and drowning the people and their cattle.

The mural within the Turbine Hall at Cruachan Power Station undergoing maintenance [November 2018]

The story claims the water washed a path through to the sea, creating the Pass of Brander. The site of a 1308 battle in the Scottish Wars of Independence, where Robert the Bruce defeated the English-aligned MacDougall and Macnaghten clans.

The mythical first section of the mural is separated by a Celtic-style cross from the modern second segment, which portrays the power station’s construction within Ben Cruachan. Here, four figures represent the four lead engineers of the project from the firms James Williamson & Partners, William Tawse Ltd, Edmund Nuttall Ltd and Merz & McLellan. They stand by the mountain, a roughly cut path running through its core.

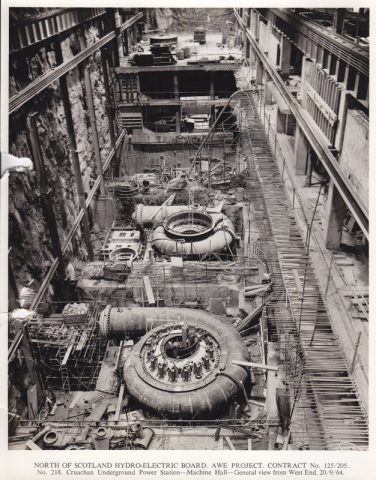

At the base of the mural are the faces of 15 men lying on their sides. These are the 15 who were killed in 1962 when the ceiling of the turbine hall caved in during construction. Their uniform expressionless faces, however, turn them into symbols of the 30-plus workers who died while digging and blasting the power station’s tunnels and constructing the dam at the upper reservoir.

Next to this is a fairy tale portrayal of Queen Elizabeth II, who wears a gold grown and holds a sceptre from which electricity flows in a glowing lightning bolt through rock, commanding the power station into life.

The final third of the mural shows the whole power station system within the mountain. The upper reservoir sits nestled in the slopes of Ben Cruachan with water flowing down the mountain to the four turbines and Loch Awe below. Viewed as a whole, the mural takes the audience from mythology to the modern power station, which continues to play a vital role in the electricity system today.

Carving the Cruachan mural

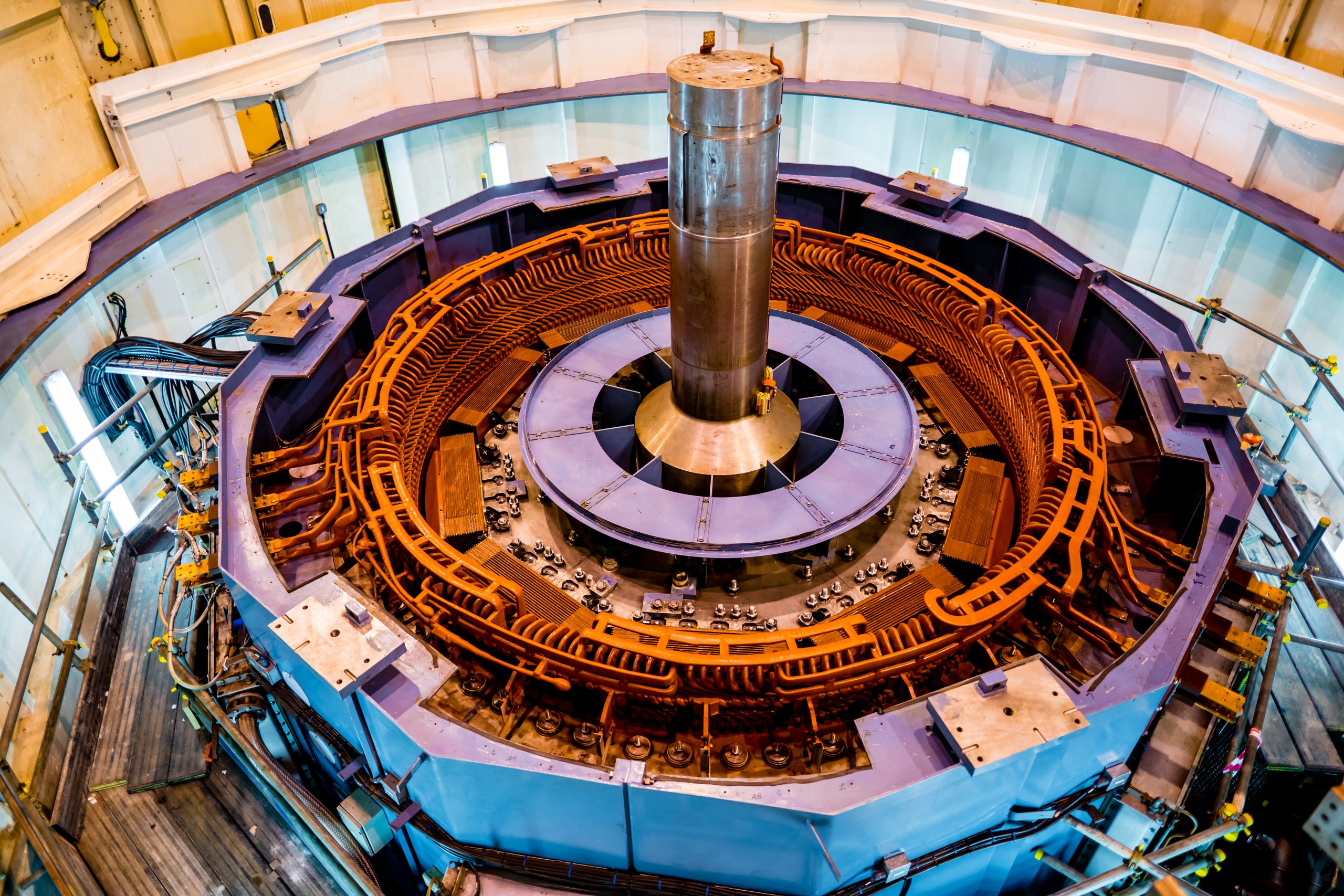

The mural was created by artist Elizabeth Falconer, who was commissioned to create it to celebrate the power station’s opening by the Queen on 15 October 1965. At the time, only two of Cruachan’s four 100 megawatt (MW) reversible turbines were completed and operational, but it was still the first station of its kind to operate at such a scale. Two of the power station’s turbines were modified with increased capacities meaning Cruachan can both use and generate up to 440 MW.

HRH Queen Elizabeth II opening Cruachan on 15 October 1965

The project came to Falconer through her husband, a native of Aberdeen who worked as an architect partner to one of Cruachan’s engineering firms. The brief simply requested she create a piece to fill the empty space on the wall of the turbine hall. Deciding to dive into the history and mythology of the mountain, she initially carved the mural in London and only ventured into Hollow Mountain years after it was first put in place, to make renovations on the work.

Cruachan Power Station was a visionary idea and represented a considerable technical and engineering achievement when it opened. The designs and construction of the reversable turbines put this site at the cutting end of modern energy technology.

So, it’s fitting the mural appears distinctly modern in its design, yet tells a story that connects this modern power station to the ancient rock it lives within.

It’s Cruachan’s mural’s location inside the mountain that makes it so unique as a work of art. However, at a time when the electricity grid is changing to an increasingly renewable system, based more around weather and geography, the connections the mural makes between Scotland’s landscape and the modern power station, make it relevant beyond the turbine cavern.

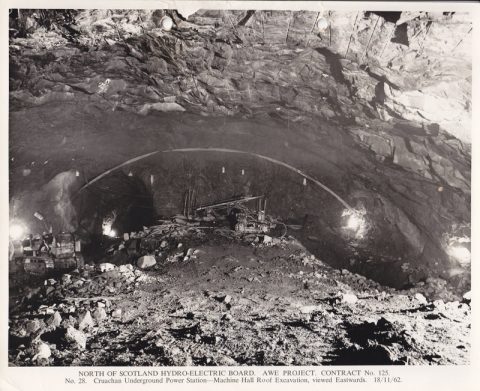

The access tunnel, cavern and the networks of passageways and chambers that make up the power station were all blasted and drilled by a workforce of 1,300 men in the

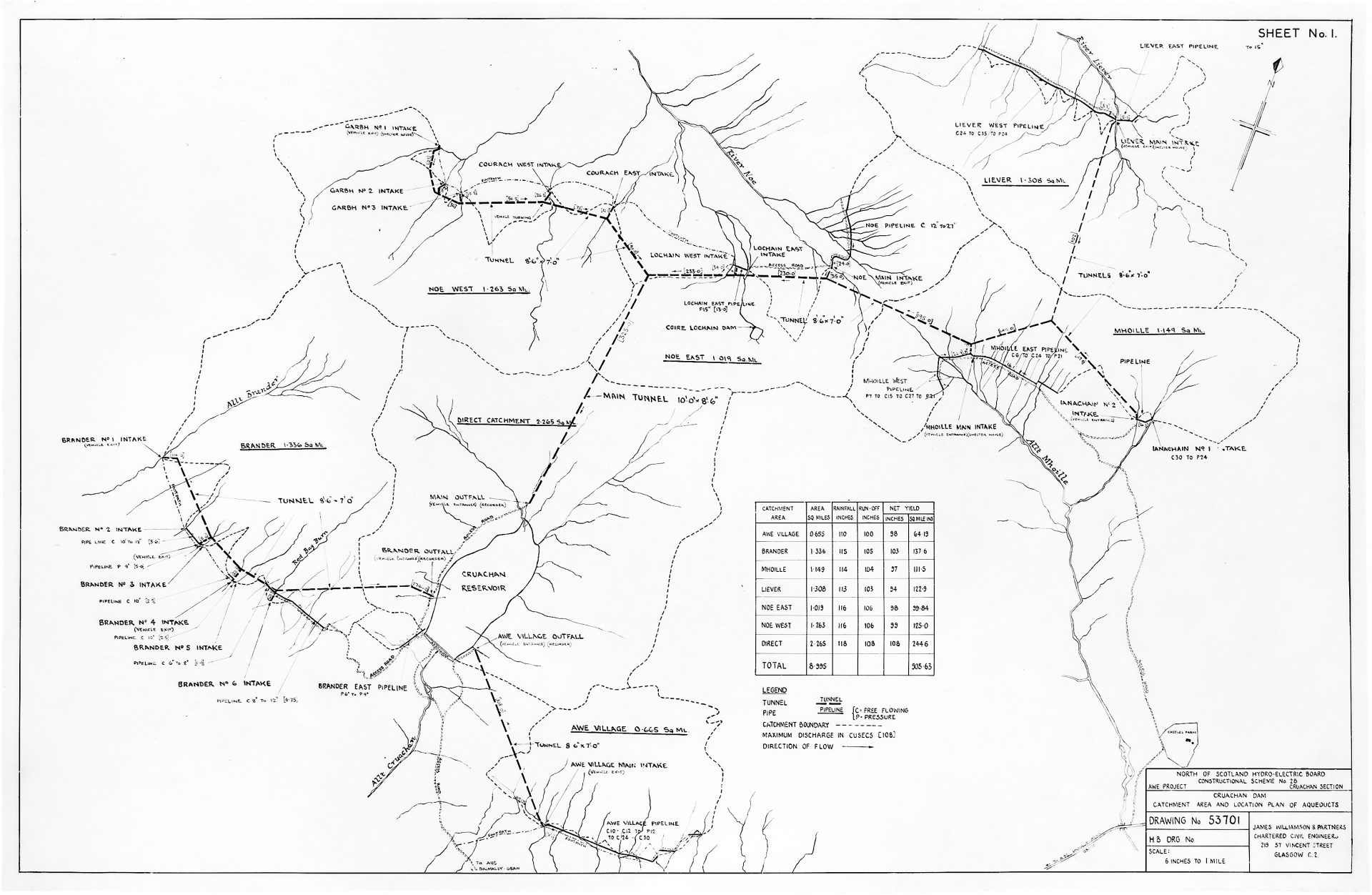

The access tunnel, cavern and the networks of passageways and chambers that make up the power station were all blasted and drilled by a workforce of 1,300 men in the  However, the reservoir also makes use of the aqueduct system made up of 19 kilometres of tunnels and pipes that covers 23 square kilometres of the surrounding landscape, diverting rainwater and streams into the reservoir. Calculating quite how much of the reservoir’s water comes from the surrounding area is difficult but estimates put it at around a quarter.

However, the reservoir also makes use of the aqueduct system made up of 19 kilometres of tunnels and pipes that covers 23 square kilometres of the surrounding landscape, diverting rainwater and streams into the reservoir. Calculating quite how much of the reservoir’s water comes from the surrounding area is difficult but estimates put it at around a quarter.