At the beginning of 2016, the world’s most sophisticated artificial intelligence (AI) beat World Champion Lee Sedol at a game called ‘Go’ – a chess-like board game with more move combinations than there are atoms in the universe. Before this defeat, Go had been considered too complicated for even the most complex computers to beat the top humans.

It was a landmark moment in the development of ever-more sophisticated AI technology. But the future of AI holds more than simply board game victories. It is rapidly finding its way into all aspects of modern life, prompting the promise of a ‘Fourth Industrial Revolution’.

One of the areas AI has huge potential is in our energy system. And this could have implications for generators, consumers and the environment.

Artificial intelligence playing traditional board game Go concept

The National Grid gets wise

Earlier this year the UK’s National Grid revealed it’s making headway in integrating AI technology into Britain’s electricity system. It announced a deal with Google-owned AI company (and creator of the Go Champion-beating system) DeepMind which is set to improve the power network’s transmission efficiency by as much as 10%.

One of the National Grid’s most important tasks is maintaining the frequency of Britain’s power networks to within ±1% of 50Hz. Too high a frequency and electrical equipment gets damaged; too low a frequency and you get blackouts. Managing this relies on ensuring electricity supply and demand are carefully balanced. But this is made increasingly difficult with the growing number of intermittent renewables – such as wind and solar – on the grid.

The ability to process massive amounts of information from a wide variety of data points (from weather forecasts to internet searches to TV listings) and create predictive models means AI can pre-empt surges in demand or instances of oversupply. In short, it can predict when the country will need more power and when it will need less.

More than this, it can respond to these fluctuations in sustainable and low-carbon ways. For example, it can automate demand side response, where energy users scale back their usage at peak times for a reward. Similarly, it can automate the purchasing of power from battery systems storing renewable energy, such as those connected to domestic solar arrays.

These solutions, which would see AI help to manage supply and demand imbalances, would ease some grid management pressures, while large thermal generators controlled by human engineers back up such automation with their continuing focus on maintaining grid stability through ancillary services.

The role of the smart city

An undoubtedly large factor in the growing sophistication of AI in the energy space is the amount of energy use data now being captured. And this has much to do with the increasing prevalence of smart devices and connected technology.

Smart meters – which will be offered to every UK home by 2020 – such as Alphabet’s Nest smart thermostat, and start-up Verdigris’s energy conserving Internet of Things (IoT) devices are just a few of the emerging technologies using data to improve individuals’ abilities to monitor and optimise their household energy use.

But at scale, information collected from these devices can be used by AI to help control energy distribution and efficiency across entire cities – and not just at a macro level, but right down to individual devices.

The idea of a central computer controlling home utilities may seem like a soft invasion of privacy to some, but when it comes to the energy-intensive function of charging electric vehicles (EVs), much of this optimisation will be carried out in public on street charge points.

As AI and smart technology continue to grow more sophisticated, it has the potential to do more than just improve efficiency. Instead, it could fundamentally change consumers’ relationships with energy.

Changing consumer relationships with energy

Start-ups in the energy space, such as Seattle-based Drift, are exploring how trends such as peer-to-peer services and automated trading can be enabled through machine AI and give consumers greater control over their energy for a lower price.

The company offers consumers access to its own network of distributed and renewable energy sources. Currently operating in New York, it uses AI to assess upcoming energy needs based on data collected from individual customers and location-specific weather forecasts. It then uses this to buy power from its network of peer-to-peer energy providers, using high-frequency, algorithmic trading to reduce or eliminate price spikes if demand exceeds expectation.

Yet to be operational in the UK, this sort of automation and peer-to-peer energy supply hints at the increasing decentralisation of energy grids, which are moving away from relying only on a number of large generators. Instead, modern grids are likely to rely on a mix of technologies, generators and suppliers. And this means a more complex system, which is precisely why automation from a central AI system could be a positive step.

Not only could it bring about optimisation and efficiency, but it could slash emissions and costs for consumers. This silent automation may not have the same headline-grabbing qualities as beating a world champion in their chosen sport, but its impact to the country could be far greater.

Homes that power themselves

Homes that power themselves

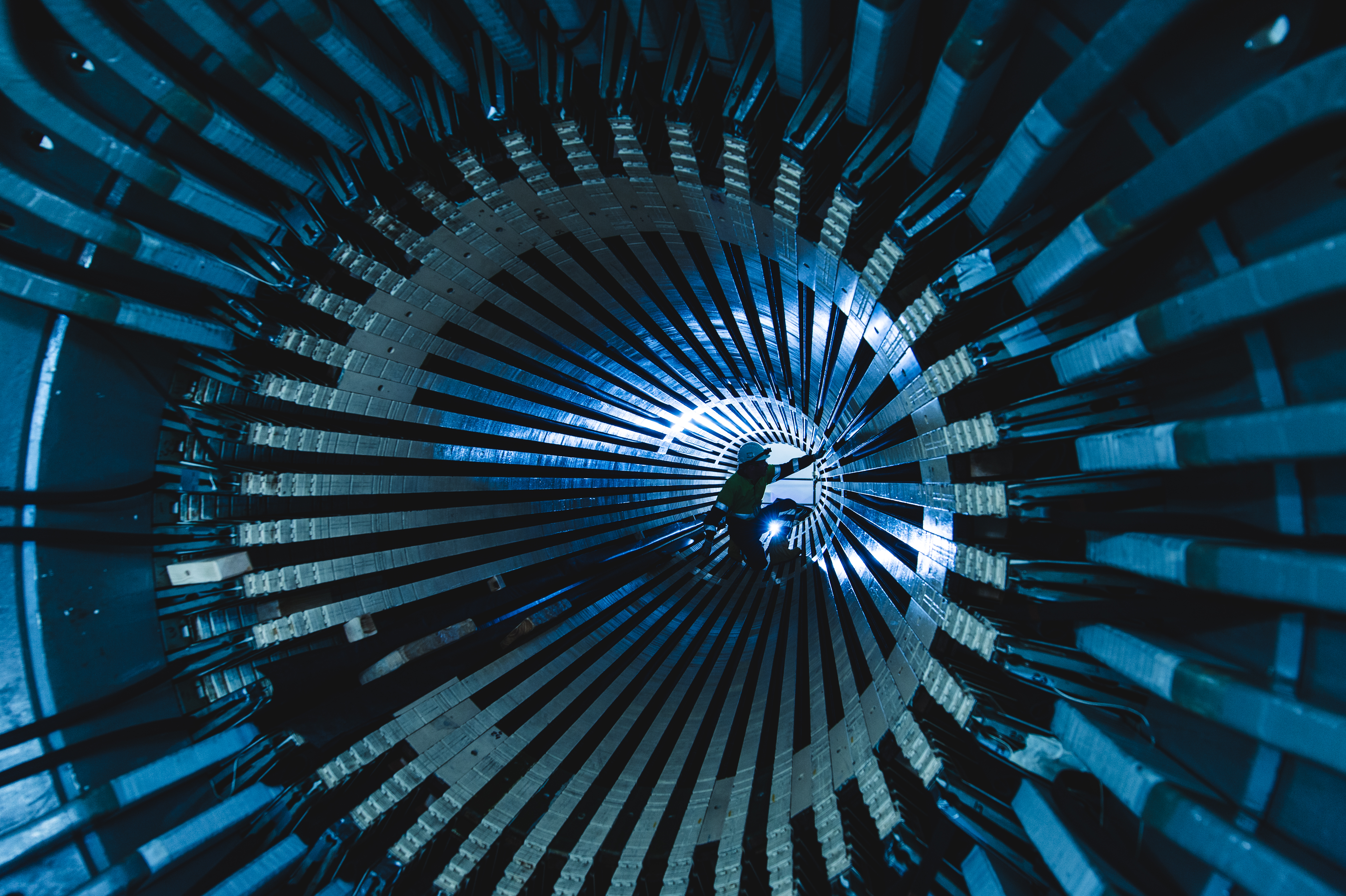

Bigger, more efficient batteries

Bigger, more efficient batteries