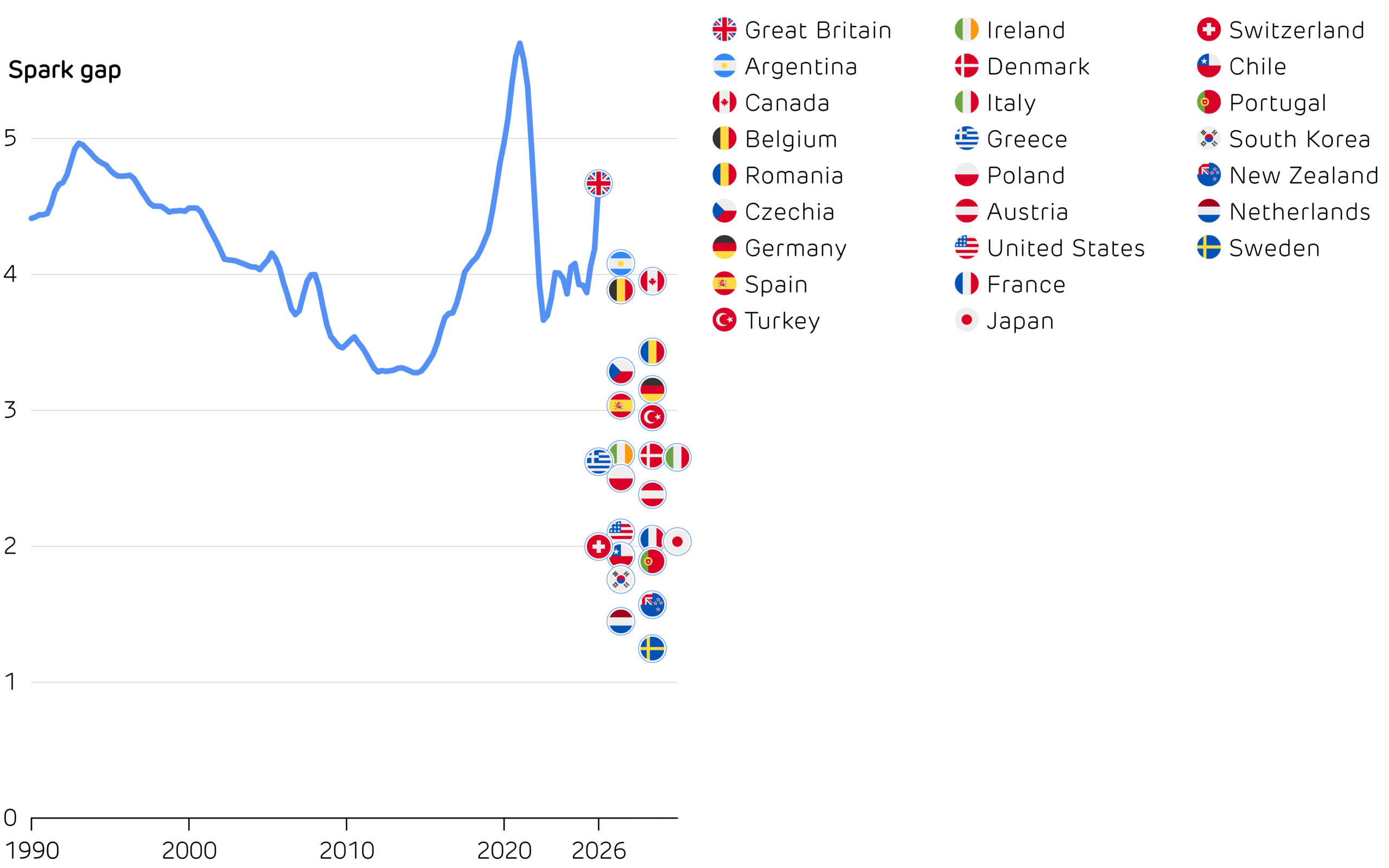

The UK is at risk of slipping behind other major economies in the shift to electric heating and transport, as new analysis shows Britain has the widest gap between household electricity and gas prices of any large country.

Figures show that electricity now costs around 4.7 times more per unit than gas for UK households, a significantly higher ratio than in France, the United States or Japan, according to a new report from academics at Imperial College London, commissioned by Drax.

In practical terms, that means it can still cost more to run a highly efficient heat pump in Britain than a conventional gas boiler, despite the electric system using far less energy and producing lower emissions.

“The UK has cleaned up how it generates electricity faster than almost any major economy. Renewables are breaking records and meeting rising demand,” said Dr Iain Staffell, lead author of Electric Insights at Imperial College London

“It’s now a critical moment for our power system. After twenty years of decline, the UK’s electricity demand has grown for two consecutive years,” he added.

Figures from the report show that consumption rose by 1.7 per cent in 2025, driven by surging demand from AI and digital services, plus rapid growth in electric vehicles and heat pumps

Data centres themselves now consume 2.5 percent of Britain’s electricity – more than the city of Birmingham – and their demand is forecast to quadruple by 2030.

At the same time, clean power has reached record levels. Renewables and nuclear power supplied more than three fifths of Britain’s electricity demand in 2025, the highest share on record. Solar output rose by 35 per cent following the sunniest year ever recorded in the UK, with a quarter of a million homes installing panels. Low carbon generation met all the growth in demand and pushed average carbon intensity down to a record 121 grams of CO2 per kilowatt hour.

Despite this progress, the UK’s spark gap – the ratio of electricity to gas prices for consumers – is the highest among 25 large economies.

By contrast, in the Netherlands and Sweden, where electricity costs about 1.5 times the price of gas, households can run heat pumps and electric appliances at a significantly lower cost than gas, providing a financial incentive for switching to cleaner and more efficient technology.

“The next step to cleaning up our heating and transport is to make sure the economics of electrification don’t let down the technology advancements. If electricity remains much more expensive than gas, uptake will naturally be slower than in countries where the price gap is smaller,” said Dr Staffell.

The report highlights that even if oversupply in oil and gas markets eases bills later this year, the relative cost of electricity compared with gas is likely to stay high. This highlights the challenge of meeting growing electricity demand efficiently and the rising importance of flexibility in the power system

Ian Kinnaird, FlexGen Assets Director at Drax, said: “Rising electricity demand will continue to increase pressure on how our system is managed.

“Record renewable generation last year came with significant curtailment costs, highlighting the importance of flexibility alongside clean power. As electric vehicles, heat pumps and data centres drive further growth, assets that can store and dispatch electricity quickly will be essential to keeping the system stable and cost effective. Expanding flexible capacity will help us to ensure more renewable power reaches homes and businesses across the country.”

ENDS

Media contacts:

Kieran Wilson

E: [email protected]

T: 07729092807