For decades the sight was the same. Day after day, trains pulling open-top wagons filled with coal would arrive at Drax Power Station. Coal was the fuel on which the station ran, but as that changes and the world moves from the dirtiest of fossil fuels to renewables and other lower carbon technologies, so too do the make-up of Drax’s daily deliveries.

Now, more than half of Drax’s power is generated from compressed wood pellets instead of coal. The trains still arrive daily, but in addition to coal carriages, more are pulling state-of-the-art biomass wagons. They’re not only the first of a kind, they’re bigger than any others on UK railways.

Moving a modern fuel

Coal and biomass are fundamentally different. Whereas coal is a durable fuel that can be left open to the elements without concern, if compressed wood pellets are left in the rain they become unusable.

In short, traditional hoppers, the large open-top train wagons used to transport coal, aren’t big enough, nor do they provide enough protection, for transporting biomass.

To deliver roughly 20,000 tonnes of wood pellets to the power station every day it would need an entirely new railway wagon. For this Drax turned to Lloyd’s Register Rail (now Ricardo Rail) and WH Davis.

Putting a lid on it

One of the first things to solve was the open top. The team designed a pneumatically operated roof for each wagon that could open and close on demand – providing easy access for loading, but suitable protection for the pellets when in transit.

A similar system on each wagon’s base was introduced to make unloading just as simple. A typical hopper design includes a wide roof that narrows into a shoot at its base for releasing fuel. The Drax wagons are different.

When they arrive at the power station, automated flaps on their underside open in stages as they pass through the biomass unloading area. This releases pellets into a sorter that delivers them into storage, ready to be used for generation. With this system in place, each train can unload in under 40 minutes.

The big problem: space

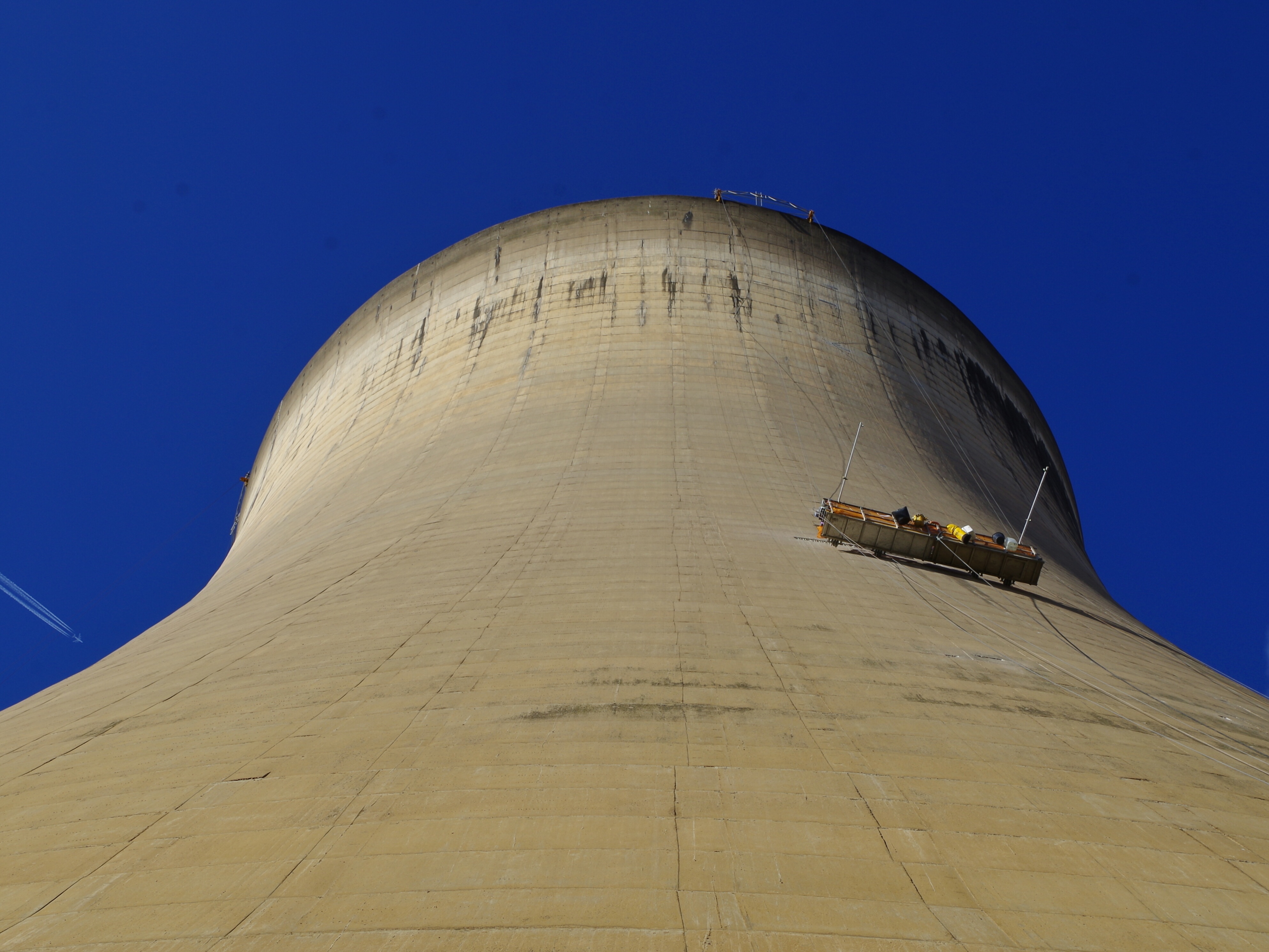

A more significant hurdle to overcome was the question of space. The obvious answer was to make the wagons bigger, but UK railways have some of the most restrictive dimensions in the world thanks to its bridges and tunnels – some of which were constructed in Victorian times.

So to get a similar efficiency out of the compressed wood pellet loads as previously obtained with coal, the wagons needed to be bigger – not in physical size, but in volume.

The team looked to the normally unused space at the ends of traditional wagons to house the braking and control equipment cubicle, while the pipework was designed to run inside the wagon’s siding, creating more inside storage space.

The result is a wagon with 116m3 capacity, almost a 30% increase in volume compared to the coal wagons. They are not only the first ever bespoke biomass wagons, they’re also the largest on UK railways.

Bigger wagons, better economy

The impact of these wagons is felt beyond just the railway lines. WH Davis is the UK’s last independent freight wagon manufacturer and relationships like this are not only good for Drax, but positively impact the wider UK economy.

A joint study by Oxford Economics for Drax calculated that in the East Midlands, where WH Davis is headquartered, Drax supports 1,100 jobs through its supply chain and the resulting economic activity. In total, the report found Drax had added £60.3 million to the local economy through indirect and induced means. Nationwide, in 2015 that impact extended to a total of £1.24 billion in contribution to the UK GDP and more than 14,000 jobs.

There’s potential for this impact to be even greater. Roughly 14 trains arrive every day at the power station from ports in Liverpool, Tyne, Immingham and Hull, delivering up to 20,000 tonnes every day to fuel the three of Drax’s six generating units that run on wood pellets. But if all six are upgraded it will mean more biomass, more deliveries and more trains.

The railways have always been a part of the power station, and in the foreseeable future it’s likely they always will be.