1967

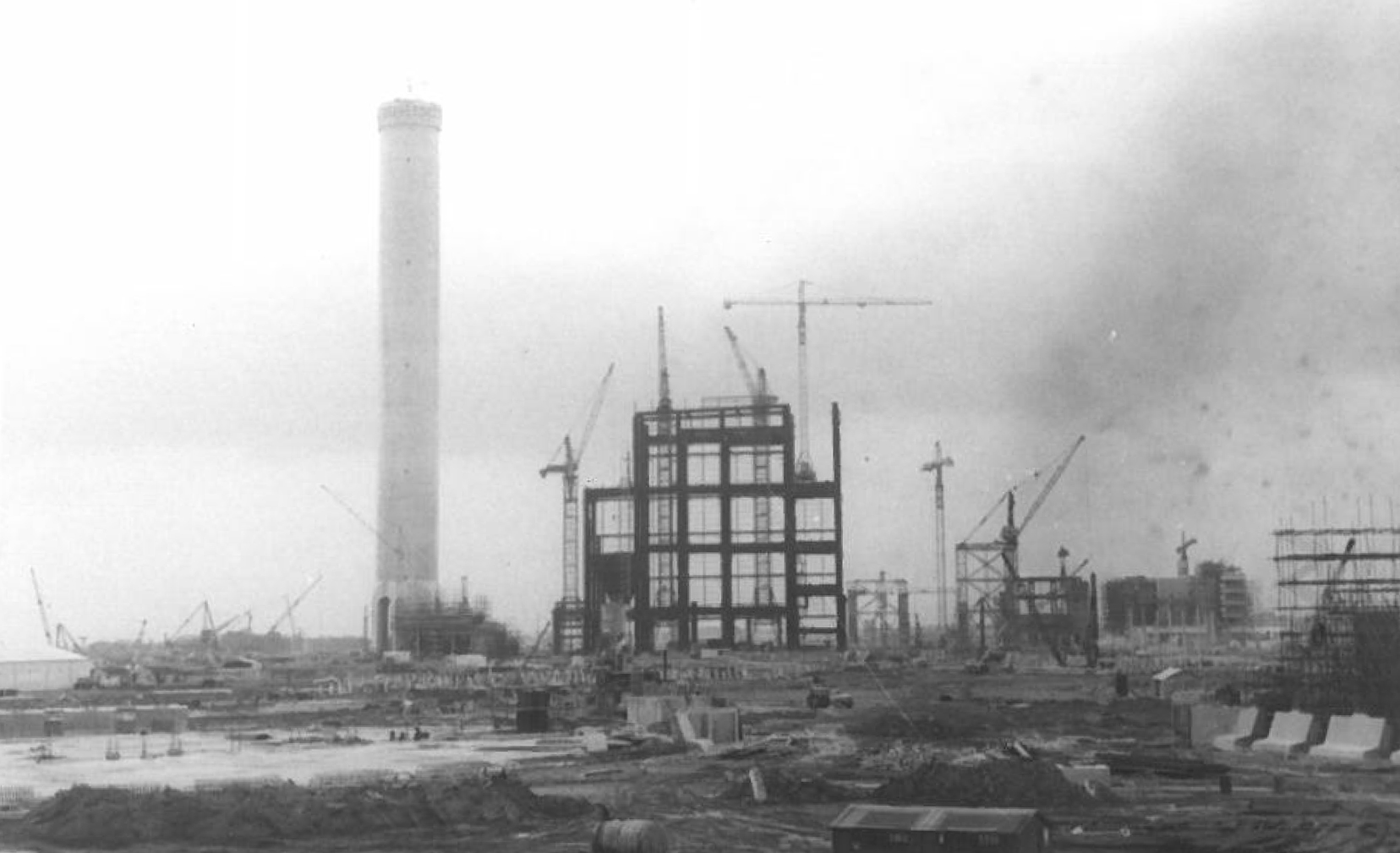

The Selby coalfield is discovered and the Central Electricity Generating Board begins building Drax Power Station to use its coal. Two other recently-built coal power stations, Ferrybridge C and Eggborough, begin generating electricity.

1974

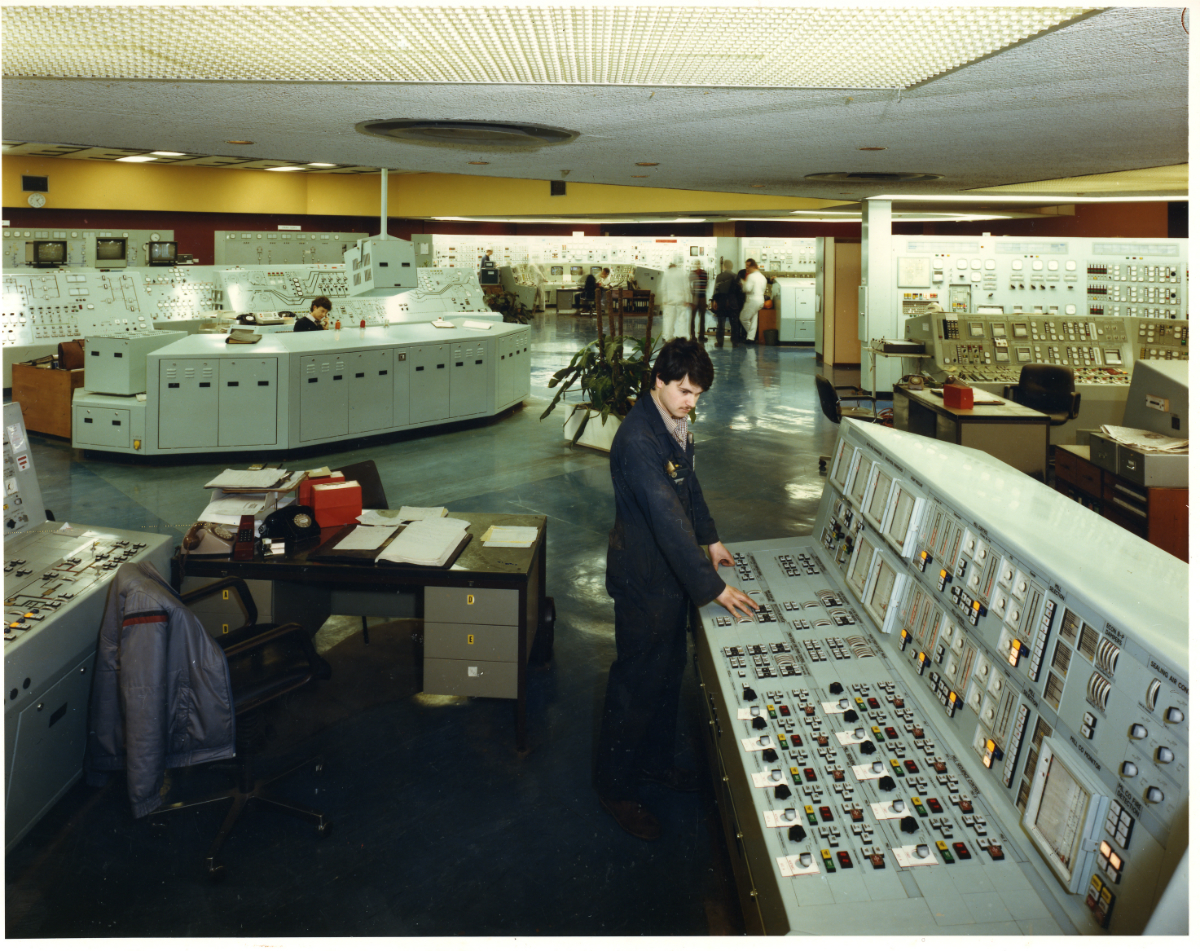

Drax Power Station begins generating electricity after its first 660MW unit is commissioned. It is the most advanced and efficient coal-fired power station ever built in the UK.

1975

Drax Power Station is officially opened with three generators and a total electrical capacity of just under 2 gigawatts (GW). It has the capability to power around two million homes.

1986

Drax doubles in size and capacity to just under 4 GW, becoming the largest power station in the UK.

1988

Drax becomes the first power station to invest in retrofitted flue gas desulphurisation (FGD) equipment. Once fully operational in 1995, it removes 90% of sulphur dioxide emissions, making it the cleanest coal-fired power station in the UK.

1990

Drax Power Station comes under the ownership of National Power, one of three power generation companies created as part of the privatisation of the electricity industry in England and Wales.

1999

The power station is acquired by the US-based AES corporation for £1.87 billion.

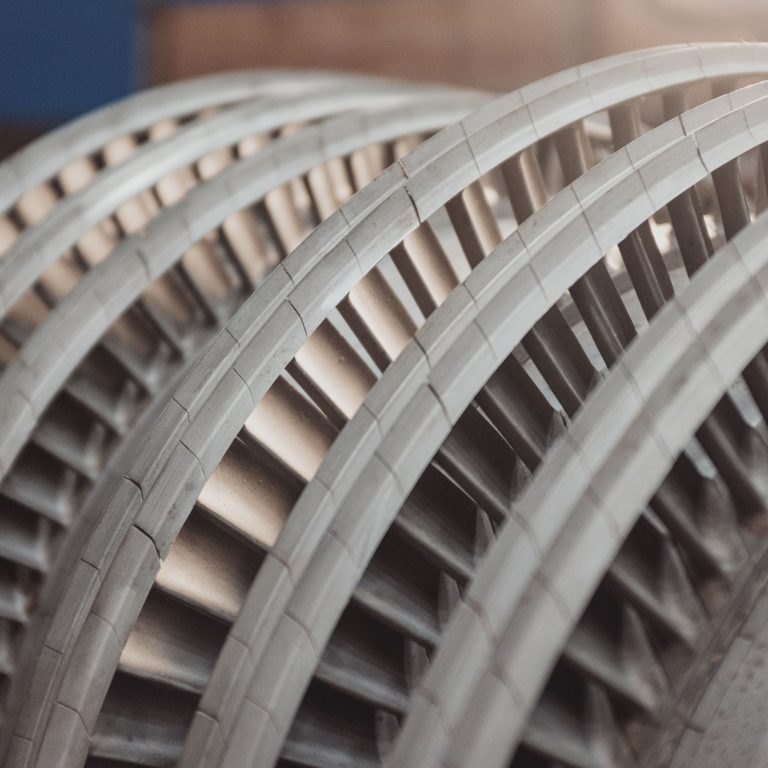

Turbine hall, Drax Power Station

2003

AES and Drax part ways after one of the power station’s major customers goes into administration. As creditors, various financial institutions take control of Drax Power Station.

2005

Drax Power Station undergoes refinancing and Drax Group plc is listed on the London Stock Exchange.

2008

Boosted-over-fire-air (BOFA) technology is retrofitted to all boilers and emissions of nitrous oxide (NOX) are reduced ensuring Drax Power Station is compliant with a strengthened Large Combustion Plant Directive (LCPD).

2009

Drax Group acquires Haven Power, enabling the group to supply a proportion of the electricity it generates directly to businesses and organisations.

The engineering team at Drax overcomes final challenges to successfully adapt boilers to combust wood pellets, proving that co-firing (the process of using two fuels to power one boiler) can work.

2012

Drax Power Station completes a five-year, £100 million plus project – the largest steam turbine modernisation programme in UK history – to upgrade its high- and low-pressure turbines. This saves around one million tonnes of carbon dioxide emissions, equivalent to taking 275,000 cars off the UK’s roads.

Drax commits to transforming the business into a mainly biomass-fuelled generator using compressed wood pellets in place of coal. It plans to upgrade the three generating units that came online in the early 1970s to run on 100% sustainable biomass, with no use of coal.

2013

The first of three power generating units is successfully upgraded to use compressed wood pellets in April.

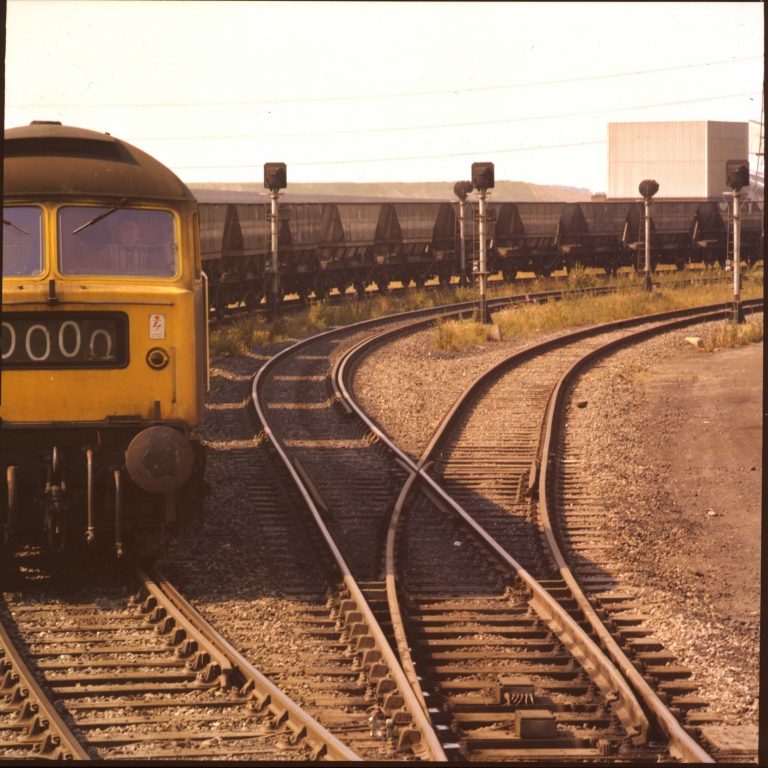

In December, new biomass receipt, storage and distribution systems to support the move from fossil fuels to renewables are officially opened. The new rail unloading bay (RUB 2) receives the first state-of-the-art biomass wagons.

2014

The second power generating unit is upgraded to biomass in October.

Additionally, Drax completes construction of four large storage domes used to house the biomass supply. Each dome is bigger than the Royal Albert Hall, can hold 75,000 tonnes of high-density wood pellets and is explosion proof.

2015

Drax Biomass completes construction of two new pellet manufacturing facilities in Mississippi and Louisiana. It also opens its port facility on the Mississippi River in Greater Baton Rouge.

Work is undertaken to partially upgrade a third coal unit to run on compressed wood pellets. Drax awaits European Commission approval for the full conversion.

Drax’s fourth UK port facility begins biomass deliveries to the power station. A first phase of the £100m development is launched by Peel Ports in Liverpool and Drax becomes the first company to transport regular rail freight over the Pennines for nearly 35 years.

2016

The group announces that 70% of the electricity it generates is through compressed wood pellets – around 20% of the UK’s renewable power. Only 30% of its electricity is coal-fired.

2017

Drax acquires Opus Energy, the UK’s largest non-domestic energy supplier outside of the Big 6.

In April, Drax Biomass purchases a third pellet mill. LaSalle BioEnergy in Louisiana is commissioned in November.

2018

Will Gardiner becomes Group Chief Executive, as Dorothy Thompson retires.

A fourth coal-fired power generating unit is taken offline at Drax. Over the summer it is upgraded to run on biomass.

In May, Drax announced that it is to pilot the first bioenergy carbon capture storage (BECCS) project of its kind in Europe which, if successful, could make the renewable electricity produced at its North Yorkshire power station carbon negative.

In December, Drax acquires Scottish Power’s portfolio of pumped storage, hydro and gas-fired generation from Iberdrola.

2019

The capacity of Drax’s power generation and storage assets increases to gigawatts (GW), following the acquisition of Cruachan Power Station, Galloway and Lanark hydro schemes, plus four combined cycle gas turbine (CCGT) power stations.

In a world first, research engineers at Drax Power Station capture the carbon dioxide (CO2) from an operational plant fuelled by 100% biomass feedstock.

The company records a 52% reduction in its carbon emissions in the first half of the year, compared to the same period in 2018. It uses its half-year financial results to announce that 94% of the electricity generated at Drax Power Station is now renewable.

Drax partners with Equinor and National Grid Ventures in September, launching Zero Carbon Humber – a partnership to build the world’s first net zero industrial cluster and decarbonise the North of England.

At COP25 in Madrid, CEO Will Gardiner announces that Drax’s world-leading ambition is to be a carbon negative company by 2030.

2020

Drax announces that almost 50 years of coal-fired electricity generation at Drax Power Station are expected to come to an end, with the end of commercial operations in March 2021 and capacity market obligations in October 2022.

Drax delivers a comprehensive support package to local communities hit by the Covid-19 pandemic. This includes laptops for school students, free energy for care homes and face masks for a York hospital. Drax Power Station cooling towers were also lit up blue in support of the NHS.

In the summer, Cruachan Power Station began a six-year, ‘world-first’ power system stability contract with National Grid ESO. A month later, Drax revealed that its hydroelectric pumped storage plant would receive cutting edge technology to improve its efficiency.

Drax announces a partnership with Mitsubishi Heavy Industries Group for a BECCS pilot project which gets underway in the autumn.

Drax joins partner organisation to form The Coalition for Negative Emissions, which sees CEOs from sectors from aviation to farming calling on the UK Government to recognise the critical role of negative emissions in reaching net zero.

2021

Drax becomes the first UK energy company to announce an initiative to improve employability for a million people by 2025 – Mobilising A Million.

In late January, Drax completes the sale of its gas assets to VPI Generation Limited.

The Group announces in February that it has signed an acquisition agreement with Pinnacle Renewable Energy.

In April, Drax completes the acquisition of the entire issued share capital of Pinnacle Renewable Inc.

Drax kickstarted a $40m development with plans for three new “satellite” pellet plants in Arkansas.

Drax Group and Mitsubishi Heavy Industries Engineering, Ltd., agreed a long-term contract for Drax to use its carbon capture technology, the Advanced KM CDR process™️

Once the biggest coal fired power station in Western Europe, Drax announced in July it had slashed its CO2 emissions from power generation by over 90 percent since 2012, radically transforming the company and securing its place as one of Europe’s lowest carbon utilities.

In October, Drax launched My Electric Vehicles, a first-of-its-kind fleet management platform for businesses, to accelerate eletric vehicle update and help support their efforts to decarbonise and meet their ESG goals.

2022

Following the acquisition of Pinnacle, North American sustainable biomass pellet producers Pinnacle and Drax Biomass rebrand to Drax in February.

In May, Drax submits application to expand iconic ‘Hollow Mountain’ Power Station. The new underground pumped storage hydro power station would more than double the electricity generating capacity.

Drax expanded its operations into Asia in July to support region’s renewable energy transition, opening a new Drax office in Tokyo, Japan.

At New York Climate Week in September, the world’s biggest carbon removal deal was announced as Drax agreed a Memorandum of Understanding (MoU) with Respira, which could see the largest volume of carbon dioxide removals (CDRs) traded so far, globally.

2023

The group launched its new global Drax Foundation in March to support STEM education and local community initiatives.

In April, Drax announced the official end of coal-fired generation at Drax Power Station in North Yorkshire, marking a historic milestone in both the company and the UK’s transformation to a zero-carbon energy future.

Drax Energy Solutions, part of the Drax Group, acquired BMM Solutions, a leading provider of EV charging and services – strengthening its fleet electrification proposition to UK business.

2024

Drax launched Elimini, its carbon removals business based in Houston, Texas. Elimini’s ambition is to deliver carbon removals at megaton scale and 24/7 renewable power.

Drax Power Station celebrated its anniversary – powering Britain for 50 years.