Hundreds of train movements each month at Drax, the UK’s biggest power station, could soon be managed by the robot – reducing the time needed to check-in fuel deliveries by up to six hours each day.

The innovative pilot project at Drax Power Station in North Yorkshire will begin this month (October) within its commercial services team to see if the use of Robotic Process Automation (RPA) can help manage the booking in of millions of tonnes of fuel delivered to the power station each year.

An average of 20 freight trains a day deliver the biomass and coal needed at Drax so it can produce the power required to keep the lights on for around six million households.

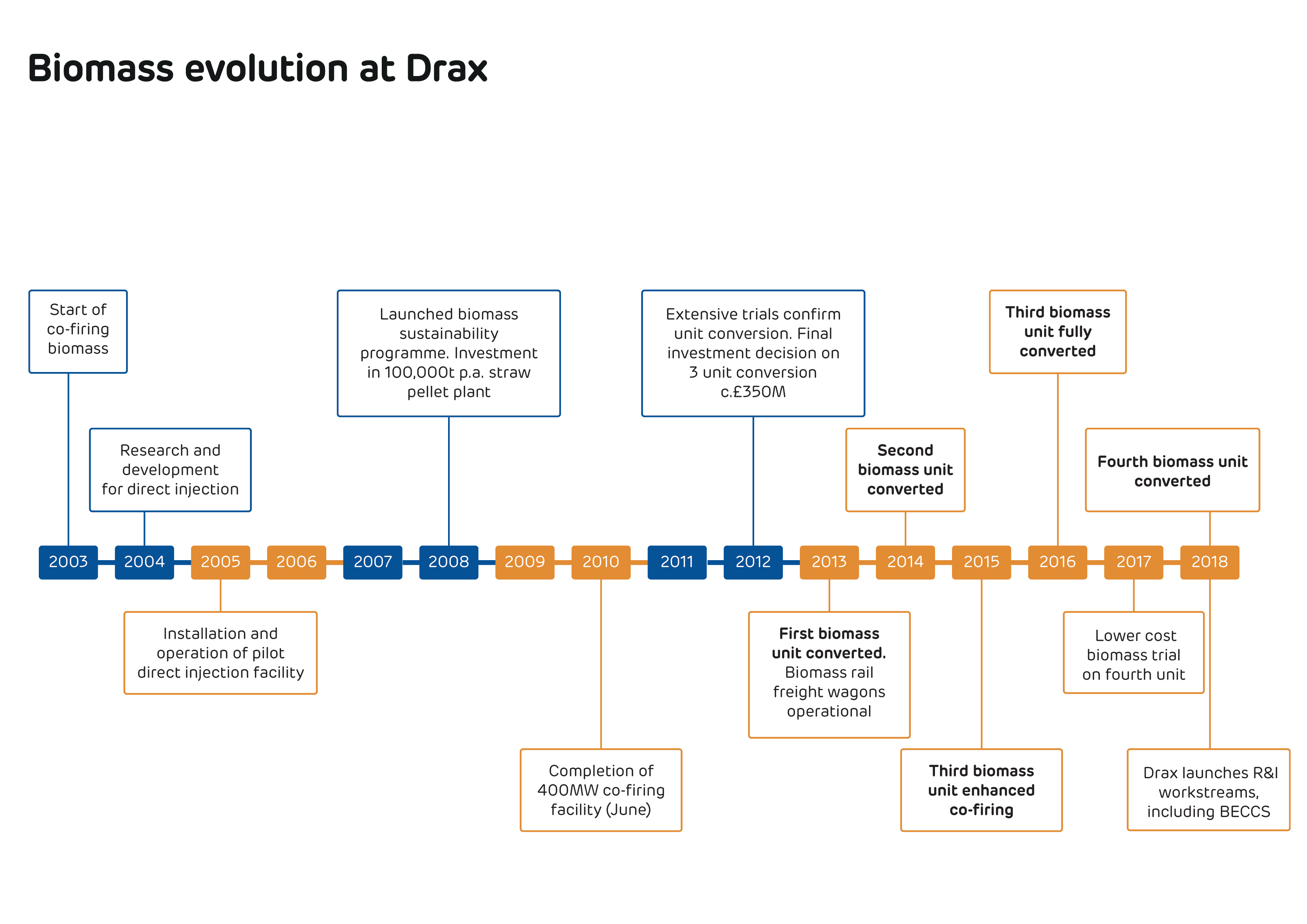

Predominantly a biomass power generator, more than 70% of the electricity produced by Drax is renewable with the majority of rail deliveries bringing wood pellets into the power station to supply its four biomass generating units.

The process of booking in each rail delivery requires the use of eight separate systems and involves 167 individual steps for one staff member to complete the task, which takes them between four and seven hours to complete, depending on the number of deliveries.

The team believes that the use of a purpose-built, digital robot, which will handle the processes automatically, could deliver the same result in just 40 minutes.

People would then be required to intervene when the robot identifies anomalies and further investigation or more detailed work is required.

They believe the time needed for manual intervention would be cut from up to seven hours per day, to just one – giving individuals six hours back each day to focus on other, more rewarding and engaging tasks.

Andy Koss, Drax Power CEO said:

“We’re constantly looking for new ways to improve our operations, to increase efficiency and make staff roles as fulfilling as possible.

“If we can use this robot technology to free up time and allow people to put their skills and expertise to good use, so they’re not getting bogged down in the admin we all love to hate, then I think we’ll see all sorts of benefits, both in terms of efficiencies but also in levels of staff motivation.

“Innovation is at the heart of our business – we were pioneers in transforming the UK’s largest coal-fired power station to become the biggest decarbonisation project in Europe, and are exploring the use of Bioenergy Carbon Capture and Storage to help us deliver negative emissions and tackle climate change. The use of RPA is another example of how we’re using new technologies to deliver our strategy.”

Beth Clifford, Commercial Services Supervisor, who will be trialling the robot, said:

“Potentially, this could massively reduce the more mundane and tedious parts of my job.

“Having more time to focus on other tasks will hopefully mean I feel like I’m adding more value, will enjoy my job more and can also take on new work which will be more interesting. I can’t wait to see how this goes and my colleagues are the same.”

Vicky Harris, Commercial Service Centre Manager, who is leading the pilot project, said:

“We’ll be measuring how effective the trial is and whether it delivers the savings we expect before a final decision is made about rolling it out.

“But we’re confident this is going to be a really positive development and we will be scoping out other processes at the power station which we think would also benefit from this kind of automation.”

The pilot project using RPA to book-in Drax’s rail deliveries will run for up to a month.

RPA is a form of automation using a software robot that mimics human actions – such as mouse clicks on a computer, but does not engage in any decision-making or the kinds of ‘thought processes’ associated with Artificial Intelligence (AI), which is the simulation of human intelligence by machines.

ENDS

Media contacts:

Ali Lewis

Drax Group Interim Head of Media & PR

E: [email protected]

T: 07712 670 888

Mark Duffell

MCD Communications

E: [email protected]

T: 01484 968 238 /07969 080 272

Editor’s Notes

- Two thirds of Drax Power Station now runs on biomass, producing enough renewable power for around four million households.

- It has plans to repower its remaining two coal generating units to develop high efficiency Combined Cycle Gas Turbines (CCGTs) with battery storage.

- If successful it could stop using coal as early as 2023, well ahead of the Government’s 2025 deadline for getting coal off the power system.

- Drax uses around 7.5 million tonnes of biomass each year, the majority of which comes from north America and Europe.

- Its UK biomass supply chain runs from coast to coast – Tyne, Hull, Immingham and Liverpool – with an average of 17 biomass trains arriving at the power station per day (over a six-day working week).

- Each train contains sufficient fuel to provide 815 houses in the UK with enough electricity for a year.

- Using rail saves approximately 270,000 truck journeys per year and is estimated to save 32,622.50 tonnes of C02 per year.

About Drax

Drax Group plc plays a vital role in helping change the way energy is generated, supplied and used. Its 2,300-strong staff operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

The Group includes:

Drax Power Ltd, which operates the largest power station in the UK, based at Selby, North Yorkshire and supplies six percent of the country’s electricity needs. The energy firm converted from burning coal to become a predominantly biomass-fuelled electricity generator. Drax is the biggest single site renewable generator in the UK and the largest decarbonisation project in Europe.

Haven Power, based in Ipswich, supplies electricity to large Industrial and Commercial sector businesses.

Opus Energy, based in Oxford, Northampton and Cardiff, provides electricity and gas to small and medium sized (SME) businesses.

Drax Biomass, is based in the US and manufactures compressed wood pellets produced from sustainably managed working forests, supplying fuel used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com/us

Clare Harbord explained that there are some major opportunities for the North to be at the heart of innovative new technologies within the energy industry, building on the region’s industrial past and now more recently as a world leader in lower carbon technologies like offshore wind, nuclear and biomass.

Clare Harbord explained that there are some major opportunities for the North to be at the heart of innovative new technologies within the energy industry, building on the region’s industrial past and now more recently as a world leader in lower carbon technologies like offshore wind, nuclear and biomass.