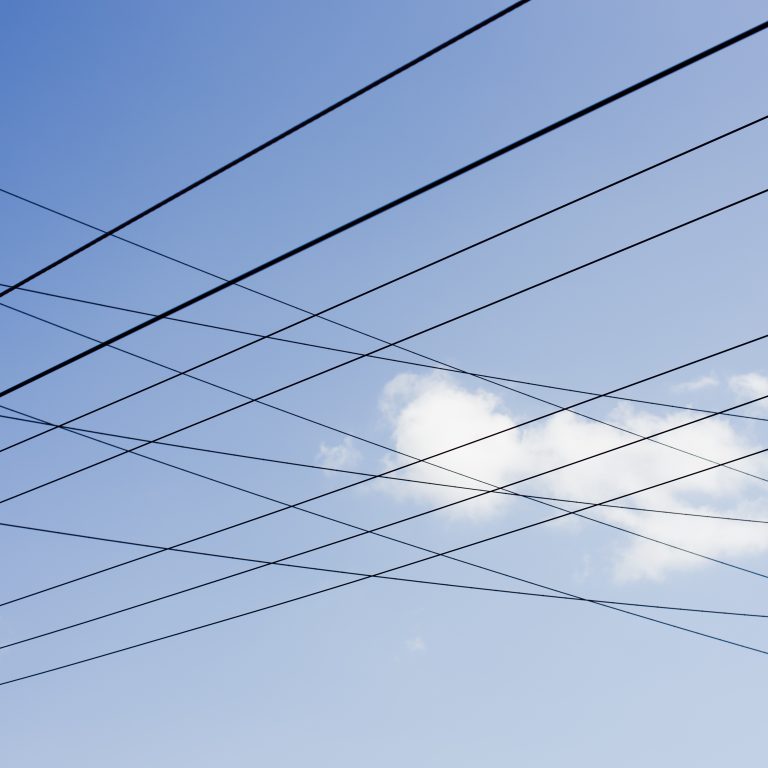

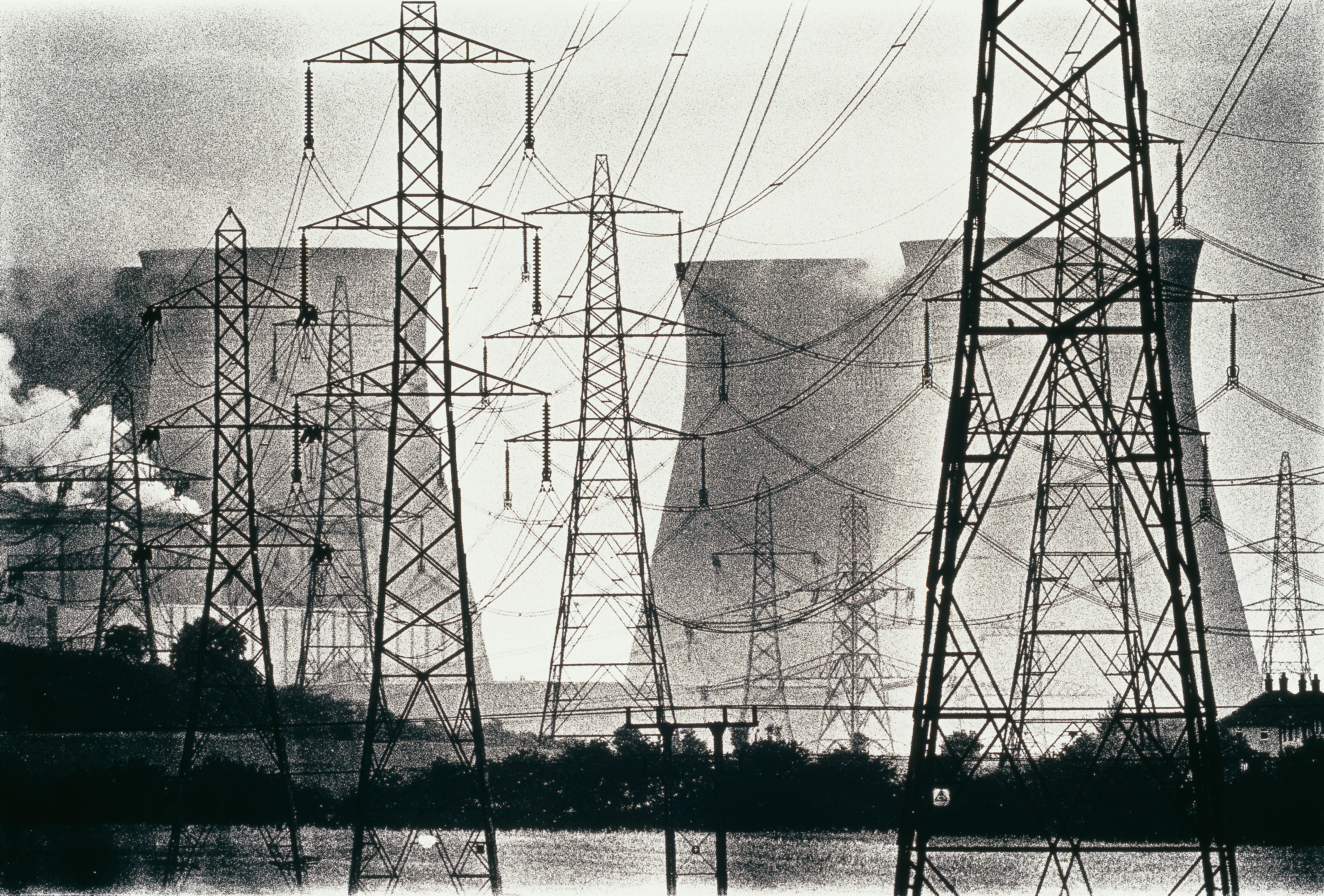

On cold, misty mornings, the powerlines, pylons and transformers that make up Great Britain’s electricity system sometimes sound a little different. Stand in a field under a powerline and, in the right conditions, the usual sounds of the countryside might be interrupted by the crackling of electricity.

This buzzing crackle, which can be referred to as a corona discharge, occurs when there’s a change from the normal conditions of a power line’s insulators enabling the electric current to partially conduct along it or through the surrounding air to earth. This can come as a result of weather conditions or deterioration of the insulators.

It’s just one of the instances where electricity changes from an unseen force powering our lights and devices to something we can hear, see and even smell.

Why can we hear electricity?

The source of electricity’s sound is also determined by one of its inherent properties: frequency. Frequency is the measurement of multiple occurrences from events, such as sound waves from vibrations, over a period of time. Any equipment that has a frequency causing mechanical parts to undergo repeated change can be audible.

For example, if we hit a cymbal with a drumstick we can hear a crash because of the frequency of the vibrations the mechanical part (in this case the cymbal) makes. We hear a guitar because its strings are plucked and pulled to create vibration at different frequencies. And we can hear an audible hum in a transformer because electric currents affect its internal structure and cause vibrations.

The buzzy tone this creates can be referred to as ‘mains hum’ and is ever present, although not always perceptible to the human ear. It becomes audible, however, when electricity (specifically alternating current – AC) is applied to a transformer.

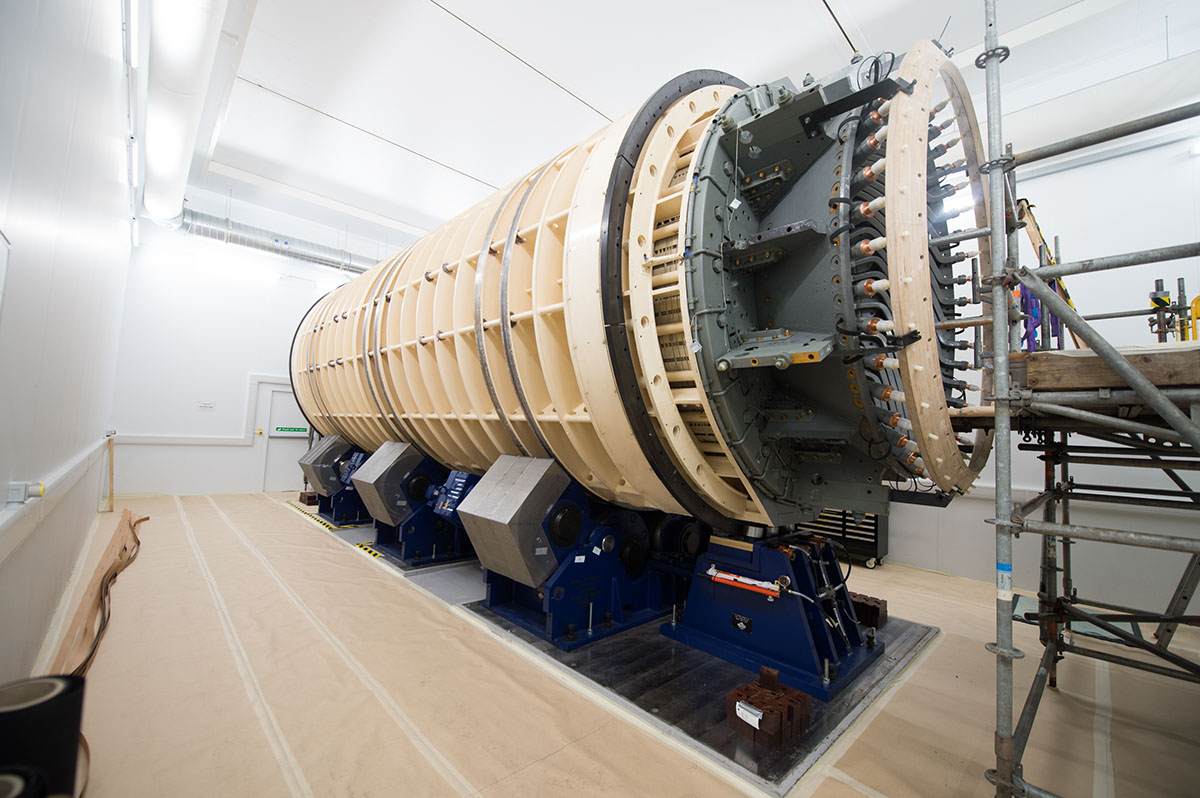

Transformers are made of lengths of copper or aluminium, which are wound around a steel laminated core. When AC is applied it magnetises the core and causes steel laminations in the transformer to expand and contract in a process known as magnetostriction. Although only small physical changes, these movements are enough to cause vibration, which in turn creates an audible hum.

The crackling overhead

With more than 7,200 km of overhead powerlines humming away constantly around the country, corona discharges are inevitable and common.

This happens when part of the insulators on a high-voltage line begins to deteriorate, is exposed to weather conditions, is damaged or contaminated, allowing electricity to partially flow along it. The surrounding air becomes electrically charged through a process known as ionisation and causes molecules to become charged and collide.

It’s these collisions in the air that make the corona audible. It can also be visible and gives off a distinct smell of ozone, the gas produced when air is ionised.

Although not dangerous to someone on the ground below, if the insulator on the powerline is left to deteriorate further it can fail completely, leading to earth faults that trip power systems.

Making use of electric hums

The sounds electricity creates may seem like a nuisance but they can also have important uses. One of the most innovative applications is in forensic analysis.

A technique called Electric Network Frequency (ENF) enables forensic scientists to validate audio recording by observing the frequency of the mains hum picked up by audio recordings, which is not audible to humans.

By comparing the frequency of the hum in a recording to a database of the country’s frequencies at given times, it’s possible to verify when and in which country the recording took place and detect any editing.

It highlights not only an innovative use of electricity, but just how pervasive and consistent a presence it is. So, while the ebb and flow of electricity through our lives often goes on without thought, it is always there, humming away while it powers modern life in Great Britain.

Can you hear this? https://t.co/RoSLxJqSNH pic.twitter.com/hqsHLMOvGg

— Drax (@DraxGroup) April 23, 2018

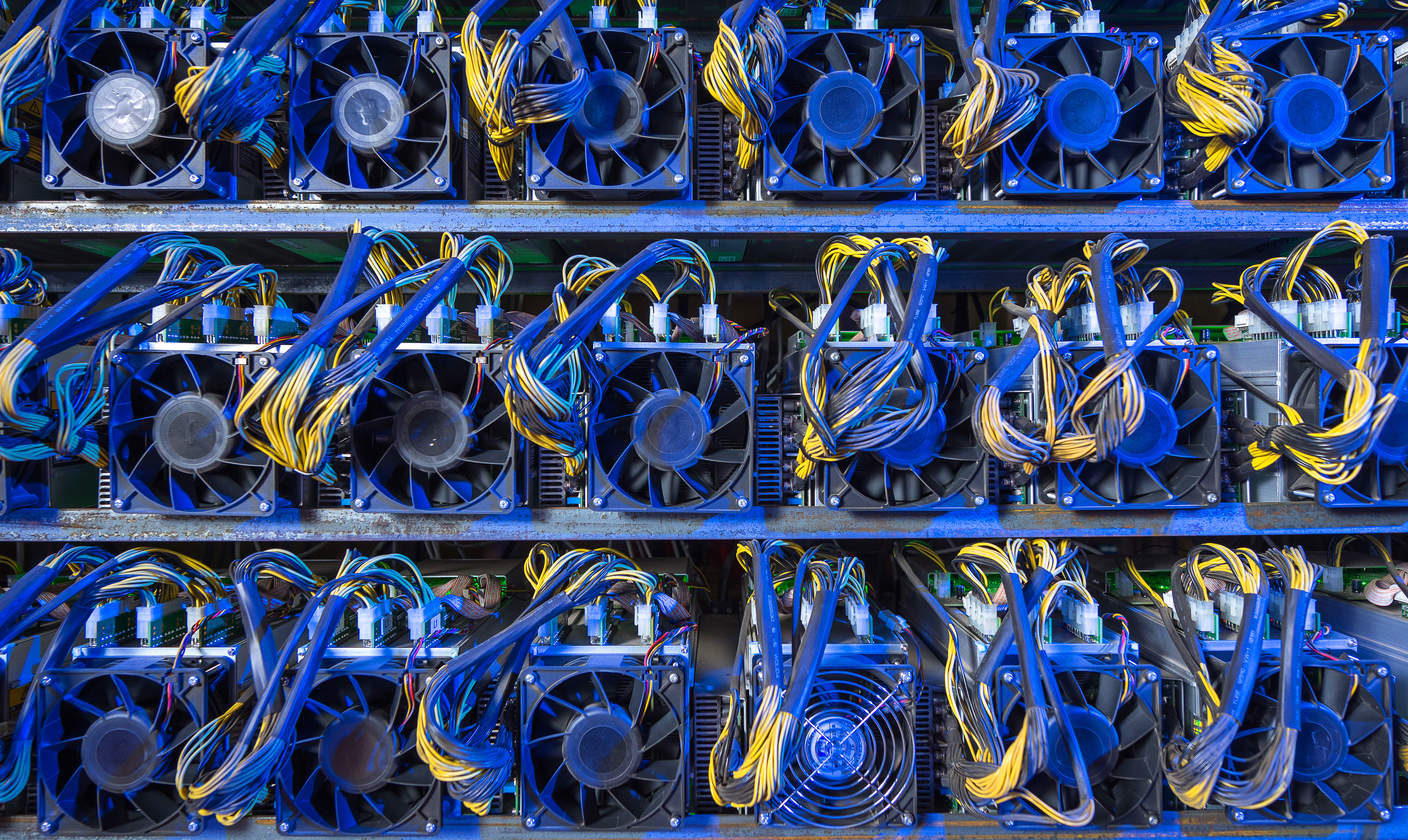

This is where the ‘mining’ computers come in, which use high-powered processing hardware to tackle the mathematical equations and ‘solve’ each transaction. The first miner to successfully crack one of these problems adds that bitcoin transaction to the ledger and is rewarded with an amount of newly ‘mined’ bitcoins – currently set at 12.5 bitcoins (BTC), worth roughly $140,000.

This is where the ‘mining’ computers come in, which use high-powered processing hardware to tackle the mathematical equations and ‘solve’ each transaction. The first miner to successfully crack one of these problems adds that bitcoin transaction to the ledger and is rewarded with an amount of newly ‘mined’ bitcoins – currently set at 12.5 bitcoins (BTC), worth roughly $140,000.

Wood construction fell out of favour in the 19th century when materials like steel and concrete, became more readily available. But new developments in timber manufacturing are changing this.

Wood construction fell out of favour in the 19th century when materials like steel and concrete, became more readily available. But new developments in timber manufacturing are changing this.