Angela Hepworth, Commercial Director, Drax

In brief:

- The voluntary carbon market will be essential in deploying engineered carbon removals technologies like Bioenergy with carbon capture and storage (BECCS), and direct air carbon capture and storage (DACS) at scale.

- The Integrity Council for the Voluntary Carbon Market is developing a set of Core Carbon Principles (CCPs).

- Drax support proposed principals if they’re applied in ways appropriate for engineered carbon removals.

- Standards around additionality and the permanence of carbon removals may apply very differently to nature-based and engineered removals, something that needs to be addressed explicitly.

There’s growing recognition, in governments and environmental organisations, of the urgent need to develop high-integrity engineered carbon removals at scale if the world has any chance of meeting our collective Paris-aligned climate goals.

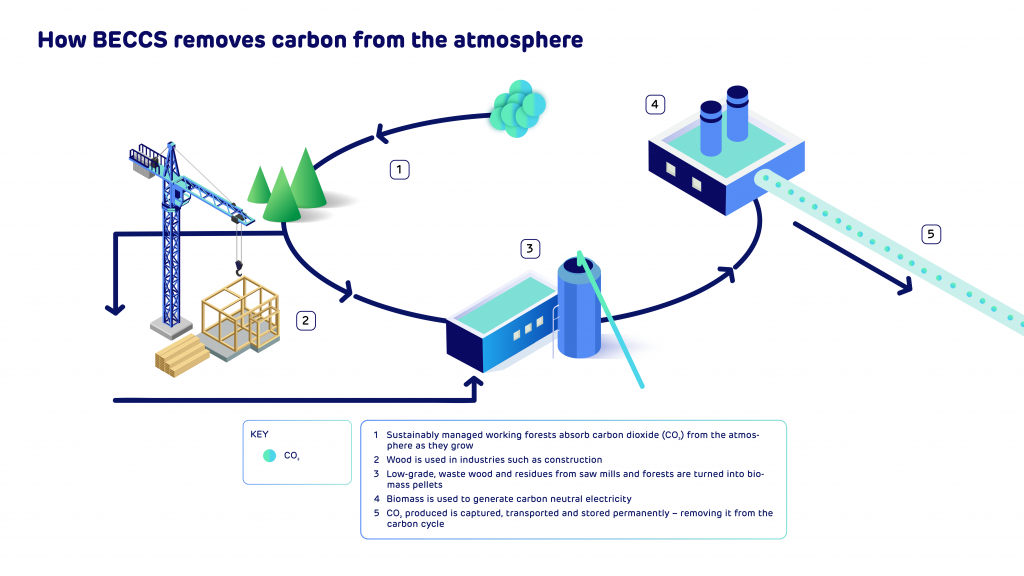

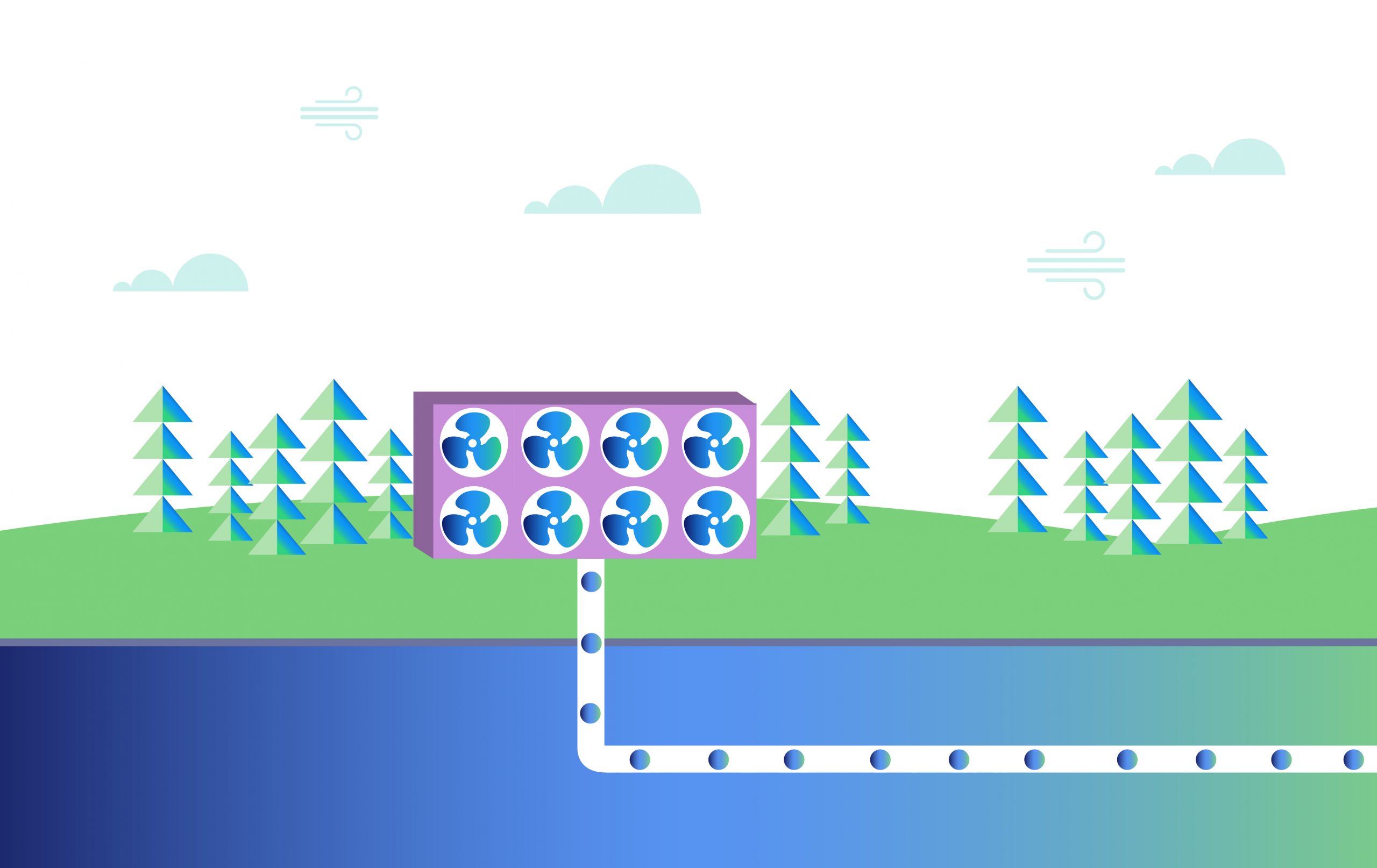

Bioenergy with carbon capture and storage (BECCS), and direct air carbon capture and storage (DACS) are two technologies on the cusp of deployment at scale that can remove carbon from the atmosphere and store it permanently and safely. The technology is proven, developers are bringing forward projects, and the most forward-thinking companies are actively seeking to buy removal credits from BECCS and DACS developers.

Yet there’s a risk that the frameworks being developed in the voluntary carbon market could stifle rather than support the development of engineered carbon removals.

Drax is a world-leader in the deployment of bioenergy solutions. Our goal is to produce 12 million tonnes of high-integrity, permanent CO2 removals by 2030 from its BECCS projects in the U.K. and the U.S. We support the development of rigorous standards for CO2 removals that give purchasers confidence in the integrity of the CO2 removals they’re buying. Such standards are also important in providing a clear framework for project developers to work to.

However, the market and its standards have largely developed around carbon reduction and avoidance credits, rather than removals. To create a market that can enable engineered carbon removals at scale, re-thinking is needed to create standards that are fit for purpose to tackle the climate emergency.

Core Carbon Principles

The Integrity Council for the Voluntary Carbon Market is in the process of developing a set of Core Carbon Principles (CCPs) and Assessment Framework (AF) intended to set new threshold standards for high-quality carbon credits.

At Drax, we welcome and support the principals proposed by the Integrity Council. However, it’s crucial they’re applied in ways that are appropriate for engineered carbon removals, and support rather than prevent their development.

Many CCPs are directly applicable to engineered carbon removals and can offer important standards for projects developing removals technologies. Among the most important principals include those stating:

- Removals must be robustly quantified, with appropriate conservatism in any assumptions made.

- Key information must be provided in the public domain to enable appropriate scrutiny of the carbon removal activity, while safeguarding commercially sensitive information.

- Removal credits should be subject to robust, independent third-party validation and verification.

- Credits should be held in a registry which deals appropriately with removal credits.

- Registries must be subject to appropriate governance, to ensure their integrity without becoming disproportionately bureaucratic or burdensome.

- Removals must adhere to high standards of sustainability, taking account of impacts on nature, the climate and society.

- There should be no double counting of carbon removals between corporates, or between countries. Bearing in mind that both corporates and countries may count the same removals in parallel, and that the Article 6 mechanism means countries can decide whether trades between corporates should or shouldn’t trigger corresponding adjustments to countries’ carbon inventories.

However, as pioneers in the field, we believe that two of the Core Carbon Principles need to be adapted to the specific characteristics of engineered carbon removals.

Supporting additionality and development incentives

The CCPs state: “The greenhouse gas (GHG) emission reductions or removals from the mitigation activity shall be additional, i.e., they would not have occurred in the absence of the incentive created by carbon credit revenues.”

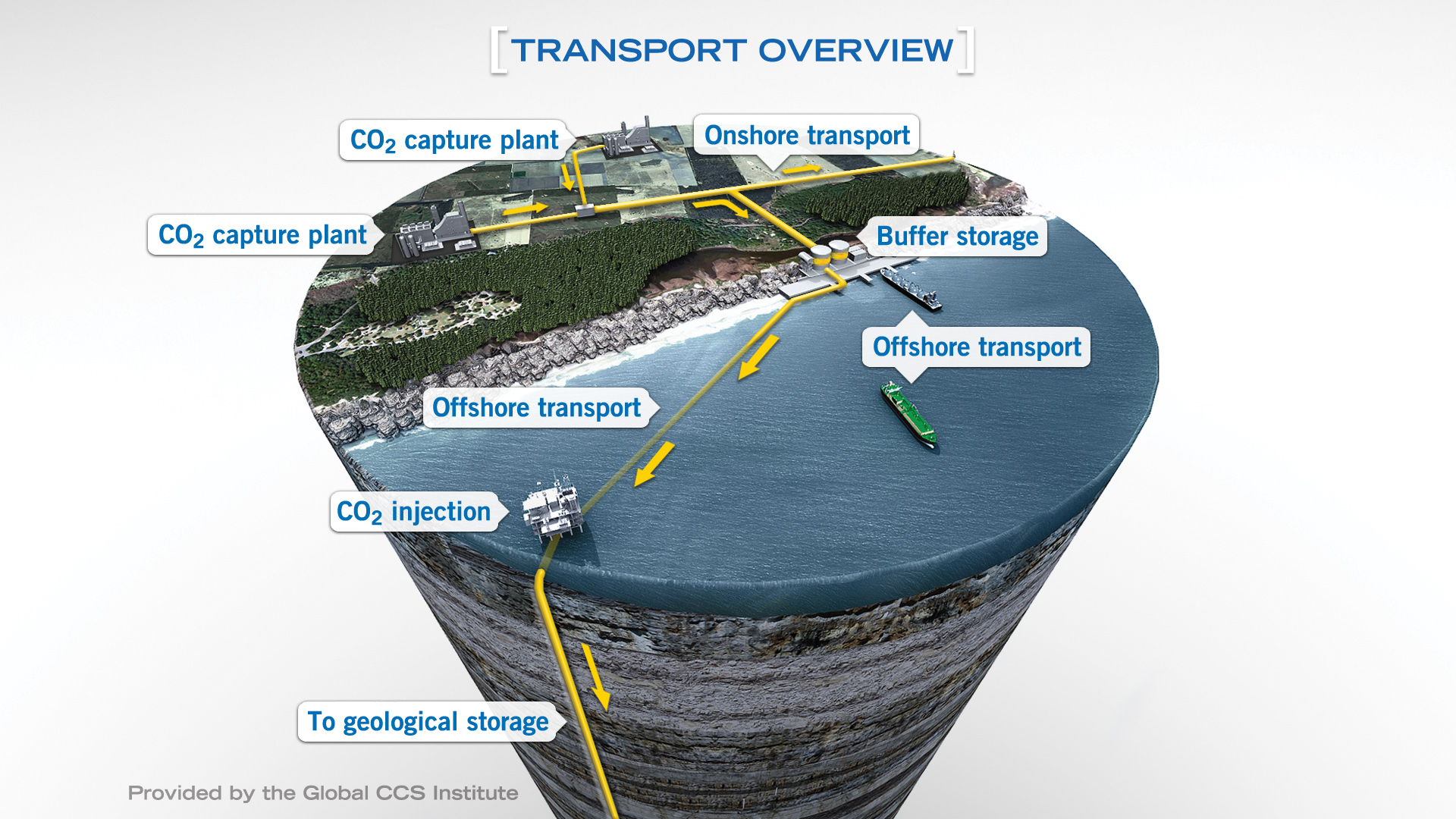

Engineered carbon removal credits such as BECCS and DACS are by their nature additional. They are developed for the specific purpose of removing CO2 from the atmosphere and putting it back in the geosphere. They also rely on revenue from carbon markets – largely the voluntary market at present, but potentially compliance markets such as the U.K. and E.U. ETS in the future.

However, most early projects are likely to have some form of Government support (e.g., 45Q in the U.S., or Contracts for Difference in the U.K.) from outside carbon credit revenues. But that support isn’t intended to be sufficient on its own for their deployment – project developers will be expected to sell credits in compliance or voluntary markets.

Engineered carbon removals have high up-front capital costs, and it’s clear that revenue from voluntary or compliance markets will be essential to make them viable.

Additionality assessments should be risk-based. If it’s clear that a technology-type is additional, a technology-level assessment should be sufficient. This should be supplemented with full transparency on any government support provided to projects.

Compensating against non-permanent storage

On the topic of permanence that CCPs state: “The GHG emission reductions or removals from the mitigation activity shall be permanent, or if they have a risk of reversal, any reversals shall be fully compensated.” A key benefit of engineered carbon removals with geological storage is that they effectively provide permanent carbon removal. Any risk of reversal over tens of thousands of years is extremely small.

The risk of reversal for nature-based credits, by contrast, is much greater. Schemes for managing reversal risk in the voluntary carbon market that have been developed for nature-based credits, are not necessarily appropriate for engineered removals.

Requirements for project developers to set aside a significant proportion of credits generated in a buffer pool, potentially as much as 10%, are disproportionate to the real risk of reversal from a well-manged geological store. They also fail to take account of the stringent regulatory requirements for geological storage that already exist or are being put in place.

Any ongoing requirements for monitoring should be consistent with existing regulatory requirements placed on storage owners and operators. Similarly, where jurisdictions have robust regulatory arrangements for dealing with CO2 storage risk, which place liabilities on storage owners, operators, or governments, the arrangements in the voluntary carbon market should mirror these arrangements rather than cutting across them, and no additional liabilities should be put on project developers.

At Drax, we believe the CCPs provide a suitable framework to ensure the integrity of engineered carbon removals. If applied pragmatically, they can give purchasers of engineered carbon removal credits confidence in the integrity of the product they’re buying and provide a clear framework for project developers. They can ensure that standards support, rather than stifle the development of high integrity carbon removal projects such as BECCS and DACS, which are essential to achieving our global climate goals.