Changing the world’s energy systems is a more complex task than just replacing coal power stations with wind farms. Moving to an energy system with more intermittent renewable sources like wind and solar will require greater levels of storage that can deliver electricity when it’s needed.

One of the long-established means of storing energy and using it to generate electricity when needed is through pumped hydropower storage. With upper and lower reservoirs of water, and turbines in between, these facilities act a bit like rechargeable batteries.

When there is excess electricity on the grid, the turbines are switched on to pump water from the lower to the higher reservoir (for example up a mountain or hill) where it’s stored. When electricity is needed, the water is released to flow from the higher reservoir toward the lower reservoir, passing through the turbines which generate electricity to send back to the grid.

Greater levels of intermittent renewables on energy systems around the world will make pumped storage all the more vital in helping to balance grids. Their mountainous locations also make pumped storage stations some of the most dramatic and interesting monuments in energy.

Here are some of the most interesting pumped hydro stations generating power and pumping water up mountains in the world:

1. The largest in the world (currently)

Bath County in Virginia, USA is dense with forests and mountain retreats, but below the scenery of the Allegheny Mountains lies the world’s biggest pumped hydro power station.

View of Appalachian mountains along Highway 220 in Warm Springs, Bath County, Virginia

The Bath County Pumped Storage Station has a maximum generation capacity of more than 3 gigawatts (GW) and total storage capacity of 24 gigawatt-hours (GWh), the equivalent to the total, yearly electricity use of about 6000 homes.

Construction began in March 1977 and upon completion in December 1985, the power station had a generating capacity of 2.1 GW. However, its six turbines were upgraded between 2004 and 2009 to over 500 MW per turbine. The power station’s upper reservoir can hold 14,000,000 cubic metres (m3) of water and its water level can drop by as much as 32 metres during operations.

While the amount of earth and rock moved during the construction of the dam and facilities would make a mountain more than 300 metres tall, the actual station occupies a relatively small amount of land to minimise its impact on the environment. The water from the upper reservoir has a use beyond power too – at times of drought it’s used to supplement river flow in the recreational area that surrounds the site.

2. The future largest in the world

Bath County will not be the world’s largest pumped hydro station for much longer. While China is already home to more of the top 10 largest pumped storage power stations than any other country, the Fengning Pumped Storage Power Plant in China’s Hebei Province will take the top position when completed in 2023, thanks to its 3.6 GW capacity.

Landscape of the Bashang grassland in Hebei, China

Construction first began on the monster project in June 2013 and is being developed in two 1.8 GW stages. The first stage is scheduled for completion in 2021, when six of the 12 planned 300 MW reversable pump turbine units roar into life.

The plant will serve Beijing-Tianjin-North Hebei electrical grid and highlights the rapid growth of renewables in the region. Fengning will act as a peaking plant to balance the expansive wind and solar parks in China’s northern Hebei and Inner Mongolia regions.

China has more installed pumped hydro storage capacity than any other country, thanks in large part to its extensive mountainous terrain (which can accommodate such facilities), as well as an increasing need to support growing intermittent renewable installations. The construction of Fengning, part of a pipeline of projects, will further the country’s capabilities, helping China reach as much as 40 GW of installed capacity in the coming years.

3. Most reversable turbines

Fengning will also take the record for the most individual turbine units in a pumped storage facility when it’s finished in 2023, a title that is currently jointly held by Huizhou Pumped Storage Power Station and Guangdong Pumped Storage Power Station. These two plants are the respective second and third largest pumped storage plants in the world today, each with eight reversable turbines.

Guangzhou City, Guangdong Province, China

While Guangdong Pumped Storage Power Station has a capacity of 2.4 GW, Huizhou has a slightly larger capacity of 2.448 GW. The increased number of turbines might mean more machinery to maintain and operate, but also offers the plants greater flexibility in how much electricity they absorb and generate.

4. Multiple dams and reservoirs

The Drakensberg Pumped Storage Scheme, located in the Drakensberg Mountains in the province of KwaZulu-Natal, South Africa, is a unique hydro facility thanks to its use of four dams. The Driekloof Dam, Sterkfontein Dam, Kilburn Dam and Woodstock Dam give the facility a generation capacity of 1 GW, and a total storage capacity of over 27 GWh. However, Drakensberg is not the largest facility in South Africa.

Drakensberg Mountains in South Africa

South Africa holds a total installed pumped storage capacity of nearly 3 GW from its four large facilities. The newest, and largest, is the Ingula Pumped Storage Scheme, which has a generation capacity of over 1.3 GW. Its name, ‘Ingula’, was inspired by the foamy river waters surrounding the facility and comes from the Zulu word for the creamy foam on the top of a milk vessel.

5. The oldest working pumped storage plant

Another country with the ideal terrain for pumped storage is Switzerland. The Alpine country’s landscape feeds water into Europe’s rivers such as the Rhine, making water a plentiful supply for the country’s energy. Hydropower as a whole accounts for around 57% of the country’s energy production and the country was one of the first to begin deploying pumped storage systems in the 1890s, although these were initially used for water management rather than supporting electricity generation.

Water dam and reservoir lake in Swiss Alps to produce hydropower

Switzerland is also home to the world’s oldest working pumped storage plant. The Engeweiher pumped storage facility was built in 1907 before reversable turbines were introduced in the 1930s. It was renewed in the early 1990s and is scheduled to continue operating until at least 2052.

6. The biggest in Europe

The Alps are also home to Europe’s biggest hydroelectric facility. In France, the Grand Maison hydroelectric power station operates in the Isère area of the Auvergne-Rhône-Alpes region, and has a capacity of 1.8 GW. During peak demand, it takes only three minutes for the station to supply its full 1.8 GW of power to the National Electricity Grid of France.

Grand Maison Hydroelectric Power Station

Sitting at an altitude of 1,698 metres the majority of the water that fills the upper reservoir, created by the Grand Maison Dam, comes from melted snow. This reservoir has a storage capacity of 140,000,000 m3 of water.

7. The biggest in the UK

Across the Channel, the UK also boasts impressive hydropower and pumped storage credentials, having used water for electricity generation since 1879. The UK has a total hydropower capacity of over 4.7 GW, including 2.8 GW of pumped storage, with the wet, mountainous landscapes of Scottish Highlands and Welsh countryside particularly well suited to hydropower facilities.

Dinorwig hydroelectric power station

The largest of these is the Dinorwig Hydro Power Station which sits at the edge of Snowdonia National Park in north west Wales, although it’s hard to spot as most of the machinery is found underground. With a total capacity of over 1.7 GW, this pumped storage plant can power 2.5 million homes and is known by locals as ‘Electric Mountain’.

8. The station lying between the lochs

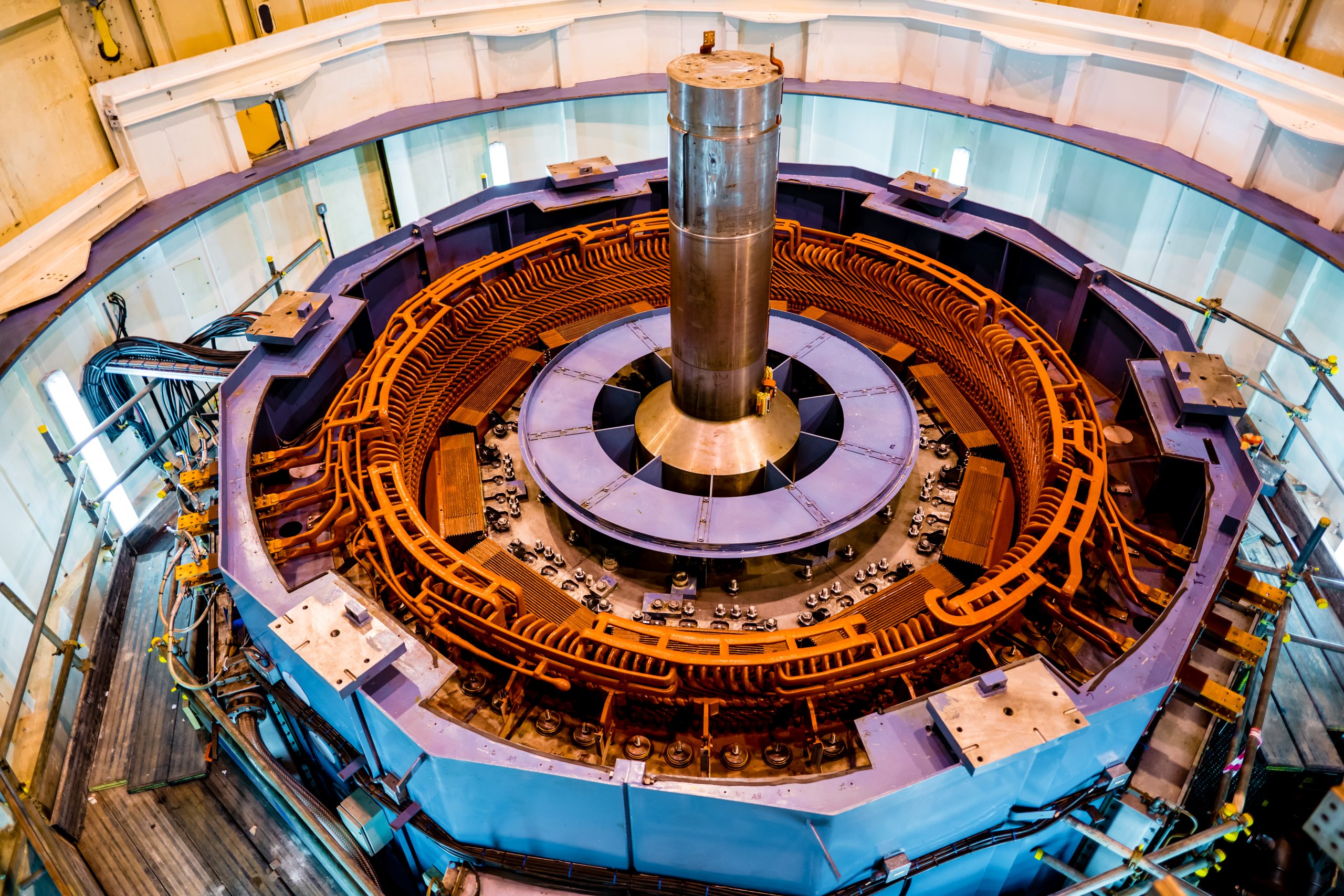

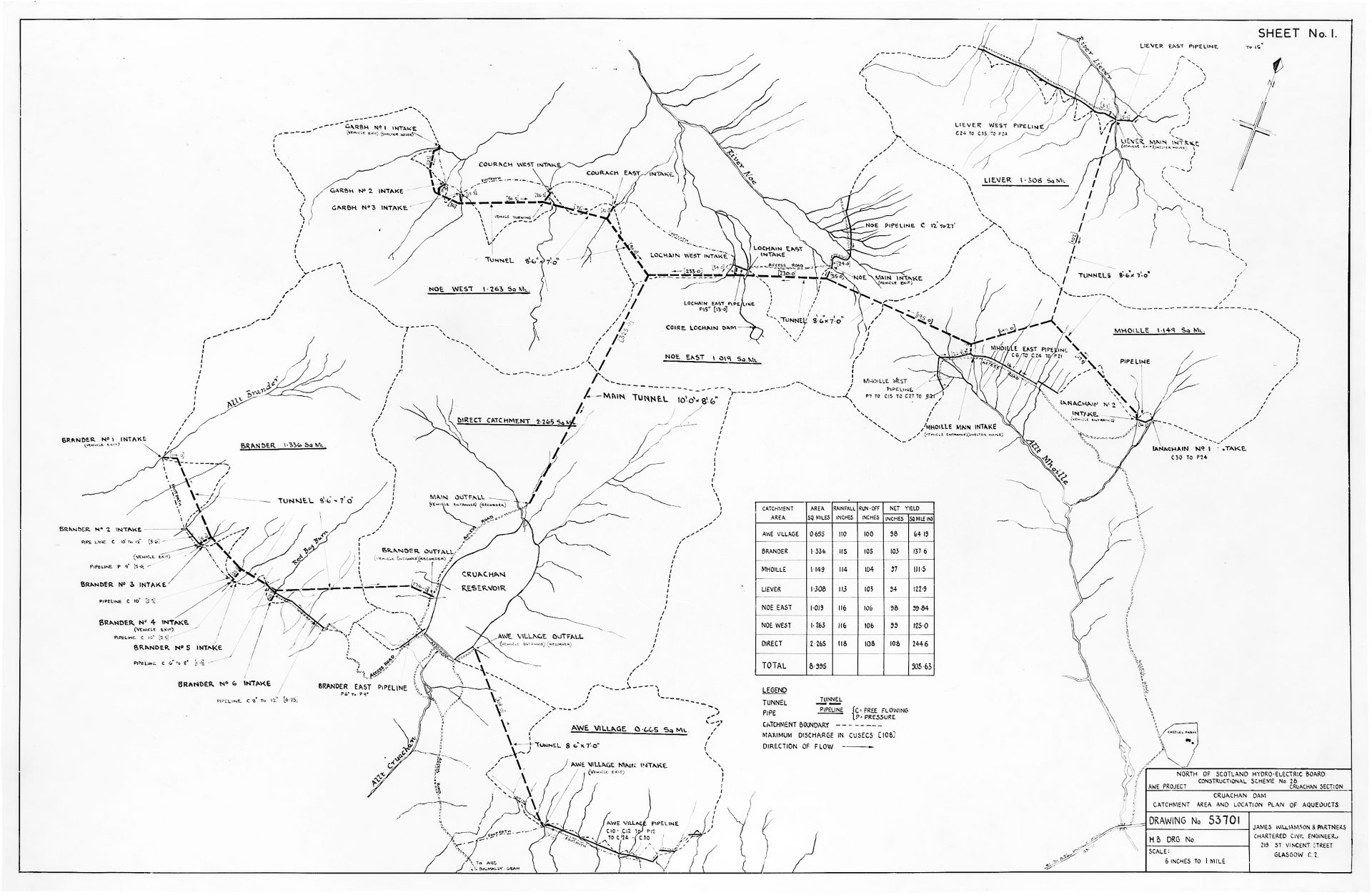

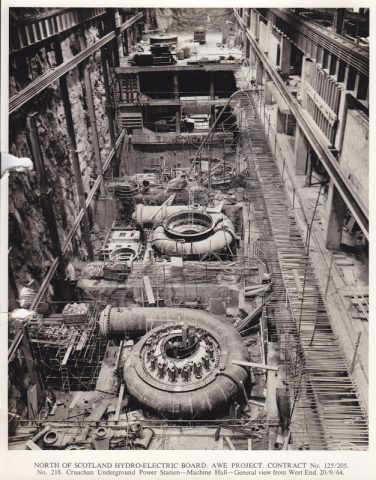

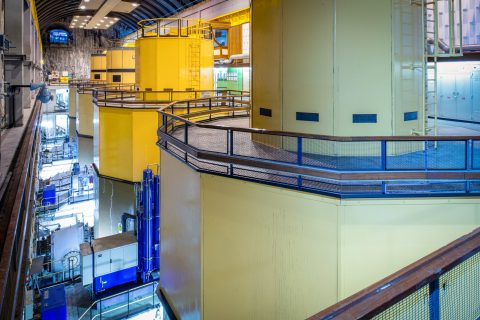

Surrounded by Loch Etive and Loch Nant, and perched on the north side of Loch Awe, Drax’s Cruachan Power Station was built between 1959 and 1965, 1 km inside of a hollowed-out mountain in Argyll and Bute, Scotland. Upon completion, the power station, also known as the ‘Hollow Mountain’, was opened by Queen Elizabeth II and can currently generate 440 MW of hydroelectric power in 30 seconds, helping to maintain stability on the electricity grid.

Cruachan Dam in Argyll and Bute

A proposed sister station, Cruachan 2, which would stand adjacent to the existing facility, could enable Cruachan to produce up to twice as much power, increasing its support of renewables coming onto the grid.

9. The world’s smallest

The Goudemand apartment building in the city of Arras, France is home to an extremely small pumped storage hydroelectricity system, with no mountain in sight. The residential building was transformed in 2012 to become grid-independent through the installation of solar panels, wind turbines, batteries and a 200 square metre (m2) open air water tank sitting on its roof. This tank, 30 metres above the ground, acts as an upper reservoir and is connected to five 10 m2 plastic water tanks in the basement, the lower reservoir.

Arras, France

While the 3.5 KWh (kilowatt-hours) capacity of the building’s micro facility is small, it provides useful knowledge to researchers, opening up the possibility of small, modular pumped storage systems to be developed and deployed at scale in the future.