- Drax’s investment of over $100 million in the new Demopolis pellet plant brings new jobs and economic opportunities to Alabama with 350 people employed during construction and 60 new direct jobs.

- The plant will produce 360,000 tonnes of sustainable biomass pellets a year from sawmill residues such as sawdust, chips and shavings.

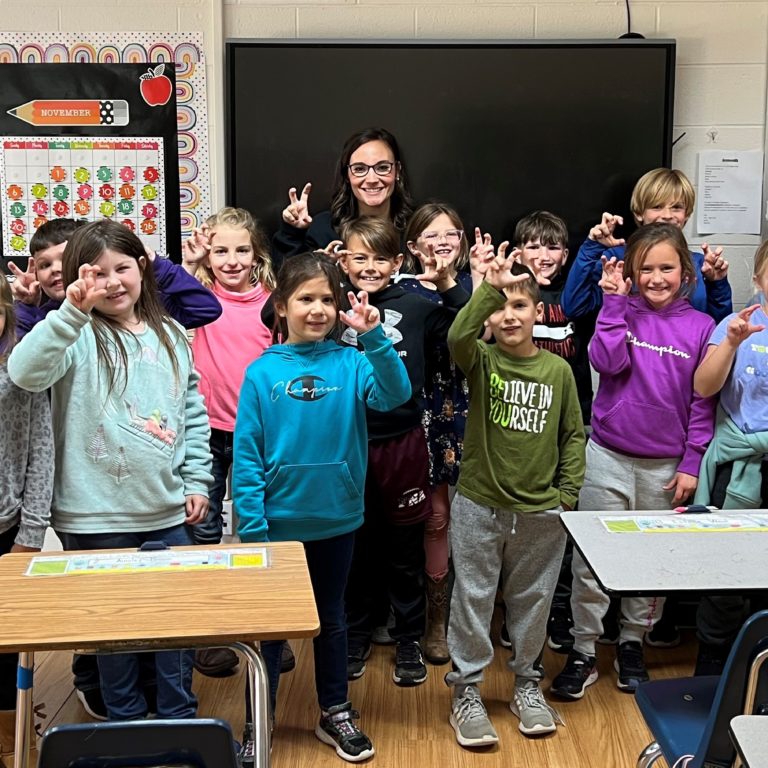

- Drax is donating $10,000 to Demopolis City Schools Foundation as it continues to support the communities where it operates.

Drax Group, the world’s leading producer and user of sustainable biomass has opened a new pellet plant at Demopolis in Alabama, bringing new jobs and economic opportunities to the town.

At full capacity the plant at Demopolis, which is Drax’s second production facility in Alabama, will produce 360,000 metric tonnes of sustainable biomass pellets a year.

Alabama Governor Kay Ivey said:

“Drax’s wood pellet plant that’s being commissioned in Demopolis represents a major investment that will drive long-term economic growth and spark significant job creation in Marengo County. The opening of this facility is an exciting development for this rural region, and I look forward to seeing Drax develop new growth plans in Sweet Home Alabama.”

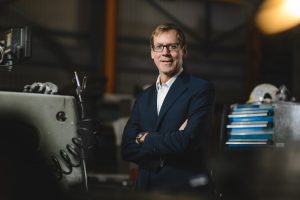

Will Gardiner (Drax CEO), Mayor Woody Collins, Ashley Coplin (Executive Director of the Demopolis City Schools Foundation) and Matt White (Drax Executive Vice President, Pellet Operations) at the official opening of the Demopolis pellet plant [April 5, 2022].

Sawmill residues used to manufacture sustainable biomass wood pellets.

Drax CEO Will Gardiner said:

“By developing these pellet plants Drax has created 120 jobs in Alabama, whilst supporting many more throughout our supply chains in the state.“I believe it’s important to support the communities where we operate and so as well as opening the Demopolis pellet mill, I’m also very pleased to announce the donation of $10,000 to the Demopolis City Schools Foundation, which will help ensure all children have access to an excellent education. I look forward to Drax continuing to work with the local community.”

Including Demopolis, Drax’s operates seven pellet plants in the US south, which use biomass sourced from the region’s sustainably managed working forests.

The Demopolis and Aliceville pellet plants support Drax’s plans to increase pellet production to meet growing demand in Europe and Asia for reliable, renewable electricity, which helps displace coal from energy systems, reducing emissions in line with global climate targets.

Drax also has ambitious plans to develop bioenergy with carbon capture and storage (BECCS). This vital negative emissions technology permanently removes carbon dioxide from the atmosphere whilst also generating renewable power – no other technology can do both.

ENDS

Media contacts:

Selina Williams

Media Manager

E: [email protected]

T: +44 07912 230 393

Annmarie Sartor

Media Manager

E: [email protected]

T: +1 318 801 0046

Editor’s Notes

- Drax owns and operates the Aliceville and Demopolis pellet plants through its 90% stake in the Alabama Pellets joint venture partnership. Two Rivers Lumber Co. LLC holds the remaining 10% economic interest.

- Drax acquired its stake in the Aliceville and Demopolis pellet plants through its April 2021 acquisition of Canadian pellet producers Pinnacle Renewable Energy.

- The pellets are made from sawdust, shavings and chips – a by-product from the neighbouring Two Rivers Lumber Co sawmill. Siting the pellet plant near a sawmill reduces infrastructure, operational, and transportation costs.

- The pellets from Demopolis are loaded onto river barges to head to the port at Mobile, Ala. for export.

- Drax plans to increase its pellet production capacity to 8 million tonnes by 2030 to help meet its own requirements, as well as its customers’ needs in Europe and Asia, amid an expected increase in global demand for the low-carbon fuel.

- Some of the pellets Drax produces in the US South East are used at Drax Power Station in England to generate renewable electricity for millions of UK homes and businesses.

- Drax’s conversion of its UK power station to sustainable biomass from coal is Europe’s largest decarbonisation project, reducing emissions from Drax’s power generation by over 95% since 2012.

About Drax

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using Bioenergy with Carbon Capture and Storage (BECCS) technology.

Drax’s around 3,000 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties. For more information visit www.drax.com

Power generation:

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

The Group also aims to build on its BECCS innovation at Drax Power Station with a target to deliver 4Mt of negative CO2 emissions each year from new-build BECCS outside of the UK by 2030 and is currently developing models for North American and European markets.

Pellet production and supply:

The Group has 17 operational pellet plants and developments with nameplate capacity of 4.6Mt, which will increase to c.5Mt once developments are complete.

Drax is targeting 8Mt of production capacity by 2030, which will require the development of over 3Mt of new biomass pellet production capacity. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet mills supply around 30% of the biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses.

Customers:

Drax is the largest supplier of renewable electricity to UK businesses, supplying 100% renewable electricity as standard to more than 370,000 sites through Drax and Opus Energy.

It offers a range of energy-related services including energy optimisation, as well as electric vehicle strategy and management.

To find out more go to the website www.energy.drax.com