- Phoenix BioPower’s study will investigate how the latest energy efficient turbine technology could reduce the costs of new build bioenergy with carbon capture and storage (BECCS) plants.

Swedish-based Phoenix BioPower and renewable energy company Drax Group, a global leader in sustainable biomass power generation, are exploring ways to drive down the costs of second-generation bioenergy with carbon capture and storage (BECCS) technology.

The feasibility study by Phoenix BioPower will look at how energy-efficient gas turbines could make new-build BECCS projects more cost effective by generating 50% more power with the same amount of fuel, when powering a 300MWe biomass plant with integrated carbon capture and storage.

The innovative top cycle turbines are up to 15 percentage points more efficient with BECCS than existing technologies used in power stations and could also be used with other renewable technologies, to support decarbonising energy systems globally.

Henrik Båge, CEO of Phoenix BioPower said:

“Working alongside Drax, a global leader in sustainable biomass power generation and BECCS, gives us an exciting opportunity to explore the next generation of negative emissions technologies together with our high-efficiency biopower technology. We look forward to working with the world-class engineers at Drax on this study to further develop these essential technologies.”

By integrating pressurised biomass gas into the turbine, instead of high-pressure steam, Biomass-fired Top Cycle turbines can almost double of the electrical efficiency from biomass compared to the traditional steam cycle.

The study will also investigate how the biomass-fired top cycle gas turbines can be utilised for other renewable technologies such as hydrogen combustion and production. The study will be based on results from Phoenix’s test facilities in Sweden and Germany.

Drax is already the largest decarbonisation project in Europe having converted its power station near Selby in North Yorkshire to use sustainable biomass instead of coal. By using the vital negative emissions technology BECCS at the site, Drax aims to go further, by becoming a carbon negative company by 2030.

Jason Shipstone, Drax Group Chief Innovation Officer, said:

“Negative emissions technologies such as BECCS will play a crucial role in the global fight against climate change and at Drax we’re planning to install this technology at our existing power station in the UK.

“This partnership with Phoenix BioPower is one of a number of options we’re investigating as part of our long-term innovation programme, which will enable Drax to understand the potential of future technological advances, so we can continue to innovate, develop and grow as a business.”

ENDS

Media contacts

Phoenix BioPower

Henrik Båge

+46 (0)734 23 22 55

[email protected]

Drax

Ben Wicks (Media Manager)

+44 7761 525 662

[email protected]

Editor’s Notes

The work by Phoenix BioPower with Drax will:

- Develop a feasibility study to identify how biomass-fired top cycle turbines can be integrated into new build BECCS power stations.

- The study will be based on results from two of Phoenix Biopower’s test sites in Sweden (biomass gasification) and Germany (ultra-wet gas turbine combustion) and will create a model based on data provided by both companies.

- The study will also investigate how gas turbines can also be utilised for other renewable technologies such as hydrogen combustion and production.

About BECCS at Drax:

- Drax aims to deploy BECCS on two of its biomass generating units by 2030 capturing and permanently storing up to eight million tonnes of CO2 a year – a significant proportion of the negative emissions the Climate Change Committee says are needed in order for the UK to reach its climate targets.

- The IPCC, UK Climate Change Committee and National Grid’s Future Energy Scenarios report all recognise the vital role biomass and BECCS will play in the UK meeting its legally binding net zero by 2050 target.

- The government’s legally binding commitment to cut emissions by 78% by 2035, in line with the Climate Change Committee’s 6th carbon budget advice, also reinforces the vital role of BECCS to delivery net zero in the UK.

- BECCS is the only negative emissions technology that generates power whilst also permanently removing carbon dioxide from the atmosphere.

About Phoenix BioPower

Phoenix BioPower, founded in 2016, develops a new technology for high efficiency biopower and a novel gas turbine cycle for ultra-wet combustion enabling the energy transition to plannable renewables and utility scale negative emissions.

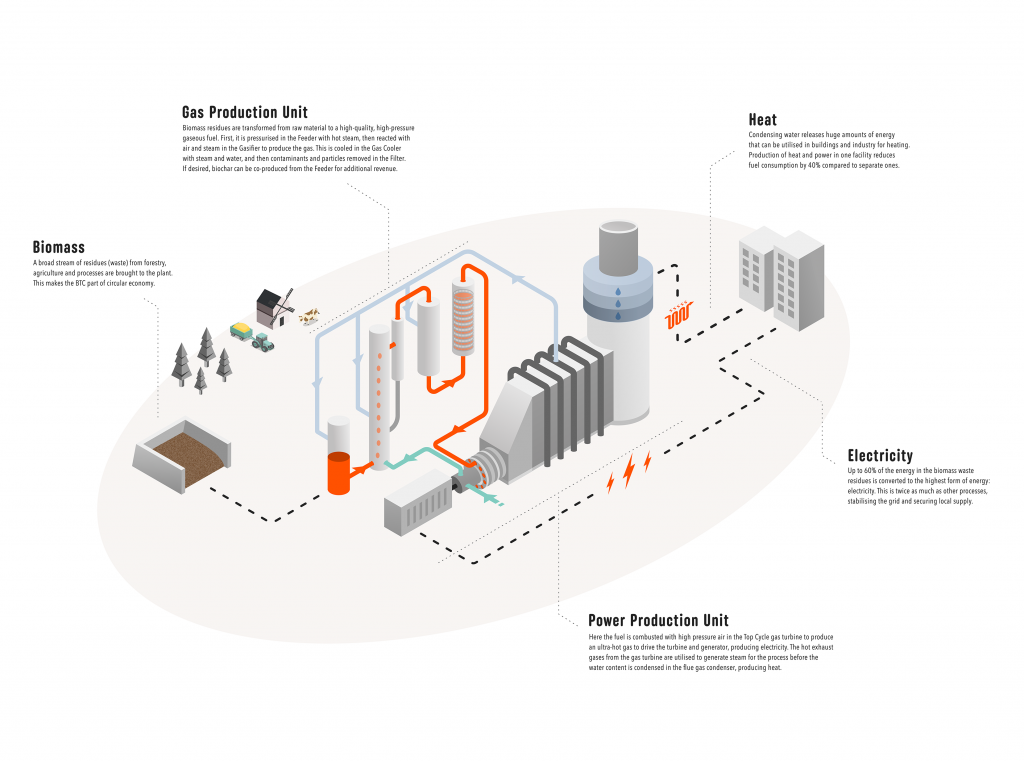

The BTC technology

The biopower technology, BTC – Biomass-fired Top Cycle, is based on the integration of pressurised biomass gasification and gas turbine combustion, enabling a near doubling of the electrical efficiency from biomass compared to the traditional steam cycle. The company targets to commission a first full-scale plant by end of 2028.

The Top Cycle gas turbine

The novel gas turbine technology Top Cycle is based on the principle of replacing excess air with steam, enabling higher power generation capabilities at lower CAPEX and high value waste heat to be used for other purposes, like CCS or District Heating, without affecting the power cycle.

The ultra-wet conditions in combustion enable very low NOx emissions, especially with Hydrogen combustion, and very stable flame conditions.

Phoenix BioPower combined heat and power (CHP) plan without carbon capture technology [click to view/download]

Customers

Phoenix BioPower is in a pre-commercial phase and will offer turn-key solutions on commercial terms to end users and plant operators with partners to assure delivery, warranties and stable operation.

About Drax

Drax Group’s purpose is to enable a zero carbon, lower cost energy future and in 2019 announced a world-leading ambition to be carbon negative by 2030, using Bioenergy with Carbon Capture and Storage (BECCS) technology.

Its 3,400 employees operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production and supply to third parties.

Power generation:

Drax owns and operates a portfolio of renewable electricity generation assets in England and Scotland. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe. It is also where Drax is piloting the groundbreaking negative emissions technology BECCS within its CCUS (Carbon Capture Utilisation and Storage) Incubation Area.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan.

Pellet production and supply:

Drax owns and has interests in 17 pellet mills in the US South and Western Canada which have the capacity to manufacture 4.9 million tonnes of compressed wood pellets (biomass) a year. The pellets are produced using materials sourced from sustainably managed working forests and are supplied to third party customers in Europe and Asia for the generation of renewable power.

Drax’s pellet mills supply around 20% of the biomass used at its own power station in North Yorkshire, England to generate flexible, renewable power for the UK’s homes and businesses.

Customers:

Through its two B2B energy supply brands, Haven Power and Opus Energy, Drax supplies energy to 250,000 businesses across Britain.

For more information visit www.drax.com/uk