The Humber Estuary is one of the most distinctive features of the UK’s eastern coastline. Viewed from above, it is a crack in the land where the North Sea merges with England – it’s this connection to the sea that has defined it as a region and led to its rich industrial history.

But in recent years, as sectors such as heavy manufacturing move overseas, the Humber has begun to sink into economic decline. These challenges are now being exacerbated by COVID-19 – almost 60% of workers in the Yorkshire and the Humber construction industry were furloughed in August 2020.

Stimulation is needed to rejuvenate the Humber and prevent lasting economic scars on the region and its working-age population. Decarbonisation offers the opportunity to rebuild the region for the 2020s and decades ahead.

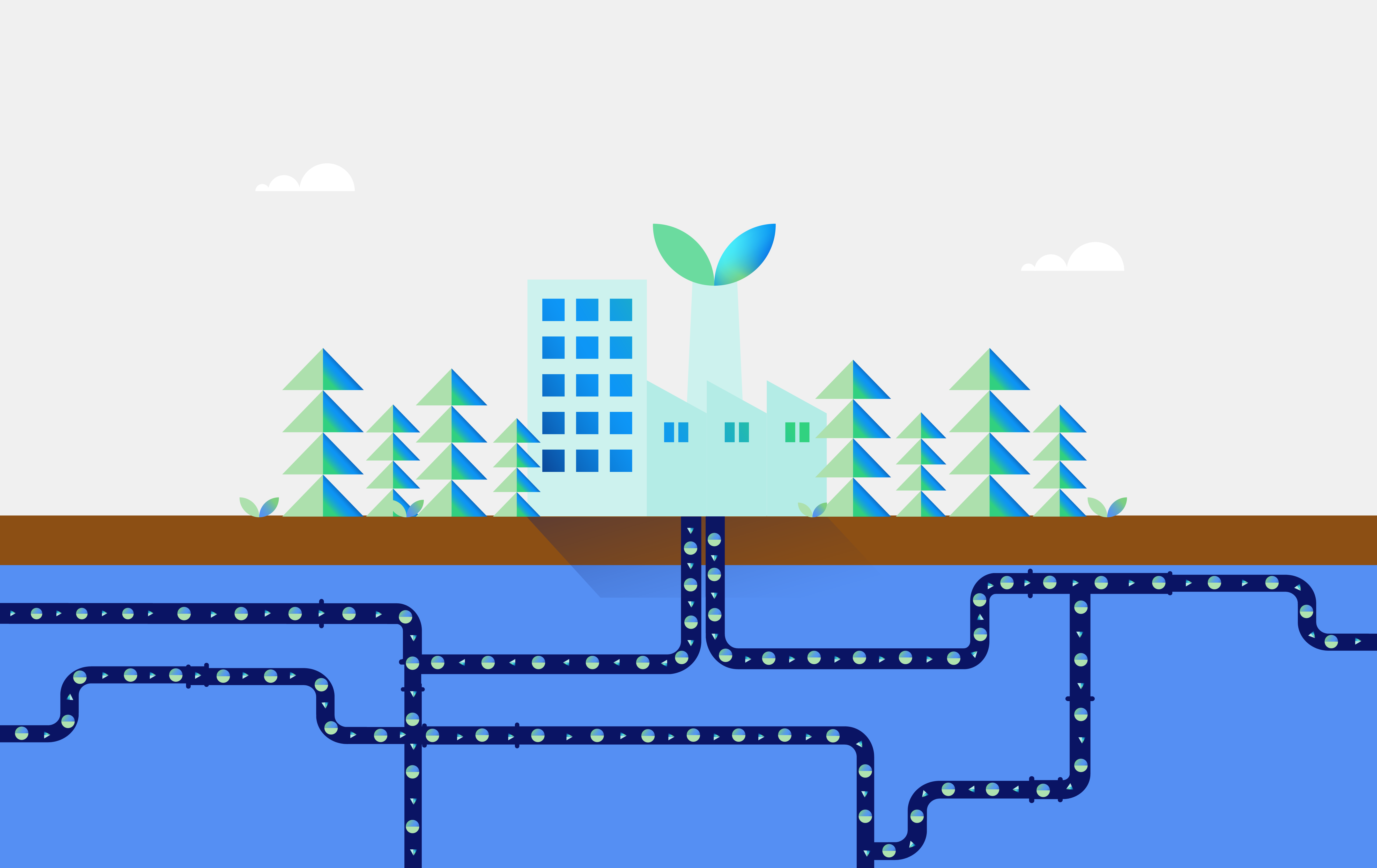

Technologies that have been identified as essential for the UK to reach its legally-binding commitment of net zero greenhouse gas emissions by 2050 include:

- Carbon capture usage and storage (CCUS) – trapping, transporting and storing or recycling carbon dioxide (CO2) from industrial processes and energy generation

- Bioenergy with carbon capture and storage (BECCS) – carbon removal from renewable, sustainable biomass power generation that leads to negative emissions

- Hydrogen production – switching processes from natural gas to this zero-emissions fuel

The Humber has unique capabilities that positions it as a hub for developing all three.

The Humber has unique capabilities that positions it as a hub for developing all three.

Zero Carbon Humber (ZCH), the partnership between a number of leading companies (including Drax), aims to bring together these essential technologies and create the foundations from which the region’s emissions-heavy industries can regain their competitive edge, create jobs and rejuvenate the area.

A new report by Vivid Economics for Drax investigates the potential economic impact of carbon capture and hydrogen. It concluded that nearly 48,000 jobs could be created and supported in the industrial cluster at the peak of the construction phase in 2027.

It’s a chance to not just revitalise a powerhouse of Northern England, but to collaborate with other industrial clusters and build a UK-wide green economy ready to export globally and attract international business to the region.

Rejuvenating the Humber

The North Sea has helped forge Hull’s strong industrial heritage of ship building and fishing. In the 1950s the flat lands of the south bank enabled post-war industries such as refining chemicals and steel to thrive.

“The region’s economy is built around the ports and accessibility to Europe and the North Sea,” explains Pauline Wade, Director of International Trade at the Hull and Humber Chamber of Commerce. “They are the biggest ports in the UK in terms of tonnage, and the energy and chemical industries hinge on materials coming in and going out of them.”

But these are also emissions-intensive industries, and as a result the Humber has the highest CO2 emissions of any UK industrial region – emitting 30% more than the second largest industrial cluster. Decarbonisation is vital in modernising and protecting these sectors, and the 55,000 manufacturing jobs they support.

“Decarbonisation brings opportunities. Many businesses in this region have that target very firmly set in their business plans,” says Beckie Hart, Regional Director of the Yorkshire and the Humber CBI (Confederation of British Industry). “Many are high polluters – they know that, but they are very keen to became part of the solution.”

Developing BECCS, CCUS and hydrogen, as well as building the infrastructure needed to capture and transport CO2, offers both immediate construction jobs and long-term skilled jobs.

The main construction period of the project would run from 2024 to 2031 and support up to 47,800 new jobs at its peak in 2027, when £3.1 billion a year would be added to the regional economy. These include up to 25,200 high quality jobs in construction and operations, as well as a further 24,400 supported across the supply chain and wider economy.

These construction roles include jobs such as welders, pipe fitters, machine installers and technicians – with immediate government backing, these jobs could be available in as little as four years. Ongoing operations will also create 3,300 long term, skilled jobs in the cluster in the early 2030s.

The supply chain needed to provide the materials and parts for the region’s industrial revitalisation will also support further indirect jobs. In fact, businesses of all kinds stand to benefit – the increased spending by workers also could support further jobs across businesses ranging from cafes to professional services. These indirect jobs go on to induce further employment and spending out across more of the economy.

Overall the report suggests an annual average of more than 7,000 indirect and around 10,800 induced jobs could be supported during the construction phase, with £452 million in indirect and £581 million in induced value added to the wider economy annually on average.

However, transformation is costly and today the Humber region receives among the lowest levels of government investment in research and development in the UK. This has contributed to a pronounced skills gap in the region, as opportunities decline, and more people fall out of the workforce.

Bridging the skills gap in the Humber

Projects such as ZCH depend on availability of skilled workforces to build and operate the next generation of energy technologies. However, the Humber currently has a low proportion of school leavers with the right qualifications to take on roles with specialist technical and practical skills.

This skills gap is only expected to get worse. The Government’s Working Futures model forecasts that from 2022 key sectors such as electricity and gas, engineering and construction in the region will require higher qualifications than are currently available in the local labour market.

The skills gap is also compounded by COVID-19. As it creates economic uncertainty it pushes more people out of work and further reduces skills in the workforce. This has a particularly pronounced impact on young people who are less established in careers, threatening to create a ‘COVID-Generation’ that feel discouraged and detached from the labour market.

But this is not an inevitability.

With the right intervention from government and business, the Humber’s workforce can be upskilled and drive a green recovery.

A number of different approaches are possible: apprenticeships have historically proved a valuable means of training the next generation of workers. Companies and schools should work together to highlight the opportunities of vocational training to school leavers.

“Universities and colleges must work a lot more closely with the businesses in the region to have an honest conversation about what they need,” explains Hart. “A good example is the Ron Dearing University Technical College. It’s a business-led college that has only been open about 18 months but has had great results from the students because they offer specific courses that the region’s employers actually need.”

For older generations of workers who have been out of the labour force for extended periods of time ‘skills vouchers’ are a timely intervention. These work by offering grants to cover the cost of flexibly retraining, meaning long-term unemployed workers of any age can ease back into new types of jobs.

Training local people for the future is key to decarbonising the Humber and creating jobs, as well as protecting industries. But a net zero industrial cluster could also have an impact beyond just the Humber.

Carbon removal in Yorkshire and the Humber

The Committee on Climate Change (CCC) has made it clear that for the UK to reach net zero by 2050 CCUS and negative emissions from BECCS are essential, as is hydrogen as a zero-carbon source of fuel. These will be needed at scale across the UK, and in the Humber. They are already underway.

Engineer at BECCS pilot project within Drax Power Station

Drax Power Station is piloting BECCS technology and has proven it can deliver negative emissions. Generating electricity using biomass from sustainably managed forests that absorb CO2 is a carbon neutral process. As part of the power generation process, adding CCUS and capturing the CO2 emitted, storing it permanently under the North Sea turns the process into a carbon negative one.

Deploying BECCS across four of Drax’s generating units would support 10,304 jobs and create £673 million in value at the peak of the construction phase. When operations get underway as early as 2027, 750 permanent operations and maintenance jobs could be created. Drax aims to operate as a carbon negative power station by 2030.

Of the 10,491 jobs supported by deploying BECCS (10,300 at the peak), 6,367 of these would be within the project’s supply chain and wider economy (9,073 in 2028).

Such supply chains needed across the North of England offer further potential to establish Yorkshire and the Humber as a hub for decarbonisation technology.

Facilities such as an Advanced Manufacturing Research Centre (AMRC) have been proven to make regions of the UK more competitive locations for advanced industries. By bringing together business with universities, they can focus on sector-specific challenges for technical industries. By creating a manufacturing hub dedicated to research and innovation in a specific industry, AMRCs also encourage ‘crowing-in investments.’ This is when private sectors investments enter into a region in the wake of government spending.

A zero carbon technology-focused AMRC in the Humber would also position the region to offer decarbonisation skills and products to other industrial clusters in the UK and further afield.

From the Humber to the world

Up the north coast from the Humber is Net Zero Teesside, a neighbouring industrial cluster with its own aims for decarbonisation. Through collaboration with clusters such as this, ZCH can offer even wider reaching benefits and enable UK-wide carbon capture, negative emissions and hydrogen.

However, for the entire UK to reach net zero, clusters all across the country must decarbonise – the report suggests as much as 190 million tonnes (Mt) CO2 could be captured and stored every year across the country.

Beyond just the clusters themselves 193,000 jobs could be created at the peak for UK deployment in 2039. These jobs would add £13.9 billion in value to the economy.

Building a strong zero carbon economy based around the combined strengths of BECCS, CCUS and hydrogen can provide the UK with a world-leading export. At a time when countries across the globe all face the same decarbonisation challenges, successfully building clusters like ZCH will allow the UK to export knowledge, skilled labour, technology and services around the world.

“As a port city, Hull has always had an international influence. The chamber of commerce was set up in 1837 by the merchant adventurers who were seafaring traders. That history is inbuilt into the local DNA,” says Wade. “Today, we’re trying to create the environment for international companies to invest and locate in the Humber.”

It serves as a further example of how investing decisively in projects such as Carbon Capture by Drax and CCUS and hydrogen clusters such as Zero Carbon Humber today will bring long term economic benefits, taking the UK from a green recovery to a world-leading green industrial powerhouse.

“The Humber has evolved from the fishing industry to a generator of high-emissions products like steel, chemicals and power,” explains Hart. “Now it is keen to be the clean corner and teach everyone else how to decarbonise. There is a single vision of where we want to go and how they want to get there jointly.”

Read the full report (PDF), executive summary and press release.

“Take the opportunity! We’re very lucky to have the chance to complete apprenticeships while working.”

“Take the opportunity! We’re very lucky to have the chance to complete apprenticeships while working.”

The Humber has unique capabilities that positions it as a hub for developing all three.

The Humber has unique capabilities that positions it as a hub for developing all three.