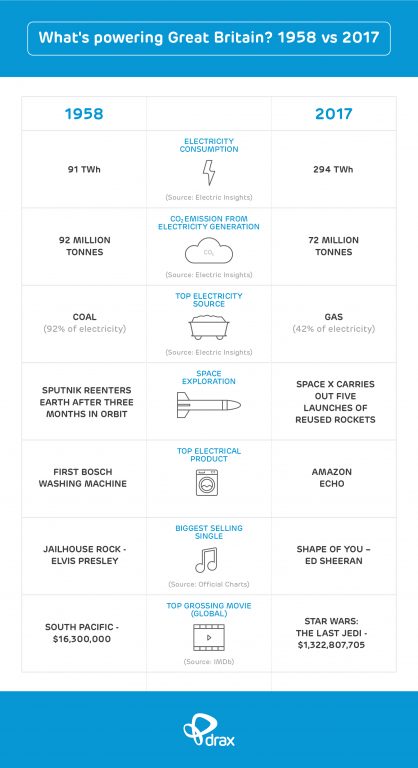

From Roman mines to the fuel behind the continent-wide industrial revolution, Europe has a long history with coal. But with reducing carbon and other greenhouse gas emissions, now firmly on the global agenda, Europe’s love for coal is rapidly declining.

Collectively, the EU aims for renewable sources to account for 20% of gross final energy consumption by 2020 and 27% by 2030. Countries in and outside the EU, as well as businesses and organisations, are setting ambitious targets to phase out coal as part of the UK and Canada-led Powering Past Coal Alliance, which Drax recently signed up to.

| European Countries | Coal-free date (according to Europe Beyond Coal *updated September 2020*) |

|---|---|

| Austria 🇦🇹 | 2020 |

| France 🇫🇷 | 2022 |

| Portugal 🇵🇹 | 2023 |

| UK 🇬🇧 | 2024 |

| Ireland 🇮🇪 Italy 🇮🇹 | 2025 |

| Greece 🇬🇷 | 2028 |

| Finland 🇫🇮 Netherlands 🇳🇱 | 2029 |

| Denmark 🇩🇰 Hungary 🇭🇺 Portugal 🇵🇹 | 2030 |

| Germany 🇩🇪 | 2038 |

| Czech Republic 🇨🇿 Spain 🇪🇸 | Phase out under discussion |

| Bosnia Herzegovina🇧🇦 Bulgaria 🇧🇬 Croatia 🇭🇷 Kosovo🇽🇰Montenegro 🇲🇪 Poland 🇵🇱 Romania🇷🇴Serbia🇷🇸 Slovakia 🇸🇰Slovenia 🇸🇮 Spain 🇪🇸 Turkey 🇹🇷 | No phase out date |

| Belgium 🇧🇪 Cyprus 🇨🇾 Estonia 🇪🇪 Iceland 🇮🇸 Latvia 🇱🇻 Lithuania 🇱🇹 Luxembourg 🇱🇺 Malta 🇲🇹 Norway 🇳🇴 Sweden 🇸🇪Switzerland 🇨🇭 | No coal in electricity mix |

This movement is not only being fuelled by an increased capacity in wind and solar generation, but also by other low-carbon energy sources enabling countries to kick their coal habits.

Aiming for 100% renewable

As myth after myth is dispelled about renewables, there are countries proving it is possible to power a modern developed nation entirely through renewable energy sources.

Up in the northern-most reaches of Europe, Iceland already generates all its electricity from renewable sources. This is split between 75% hydropower and 25% geothermal power. Geothermal not only offers a renewable source of electricity but also hot water for heating the volcanic island nation.

A geothermal power station steams on a cold day in Iceland

Hydropower is also a key contributor to Norway’s renewable ambitions. With more than 31 gigawatts (GW) of installed hydropower capacity, Norway is able to rely on it as a source of electricity and export its plentiful oil and natural gas reserves to countries still dependent on fossil fuels.

Many parts of Europe are well suited to hydropower, with reliable rainfall and the mountainous topography necessary to construct dams and power stations. Parts of Austria, Romania and Georgia also make substantial use of hydropower as a source of electricity.

Artificial Lake behind the Bicaz Dam at sunset, Romania

For countries without this access to large-scale hydropower, it’s the increased installation of renewables that holds the key to eliminating the need for coal.

Growing renewable generation

Last year saw electricity generation from renewable sources overtake that from coal for the first time thanks to continuous expansion of wind, solar and biomass capacity around the continent.

Between 2010 and 2017, generation from wind, solar and biomass installations in EU countries more than doubled from 302 terawatt hours (TWh) to 670 TWh, according to Eurostat, driven primarily by an increase in wind capacity. As a source of renewable electricity wind has already proved capable of generating major portions of a country’s demand –managing to meet 44% of Denmark’s overall demand in 2017. This was after previously producing a 40% electricity surplus one day for the country, allowing it to export the emission-free electricity to neighbours.

Wind turbines on the east coast of Sweden

Across the EU, generation from wind more than doubled from 150 TWh to 364 TWh from 2010 to last year, while solar generation grew five times from 23 TWh to 119 TWh and biomass jumped from 129 TWh to 196 TWh. By contrast, coal and lignite fell from 818 TWh to 669 TWh.

These renewable electricity sources, along with hydropower, now account for 30% of EU countries’ collective electricity generation. And while coal generation continues to drop, other low carbon energy sources, particularly nuclear, still play essential roles in many European energy systems.

From coal to low carbon

Sweden is one of the leaders in renewable electricity generation, setting 2040 as the date to move to totally renewable energy. However, while it currently counts 6.5 GW of wind capacity installed and has already exceeded its 2020 renewable generation goals, the country’s 10 nuclear reactors still make up 40% of its electricity output. Sweden aims to phase-nuclear out of its energy mix, but this will force it to import more power from neighbours to meet demand.

France is even more dependent, with nuclear making up 75% of its electricity production and earning more than €3 billion a year for the country in exports. It aims to reduce its nuclear generation to 50% with president Emmanuel Macron claiming continued nuclear generation offers “the most carbon-free way to produce electricity with renewables.”

Fessenheim Nuclear and Hydroelectric Power Plants in Alsace, France

As a reliable and low-carbon source of electricity, the most modern nuclear power stations add a certain amount of flexibility to grids enabling greater adoption of intermittent renewable sources. Across the EU nuclear made up a quarter of electricity generation in 2017.

Gas in the transition

Much more flexible than nuclear, gas plays an essential role in many countries. It accounted for 19% of electricity generation in the EU last year and produces around half the CO2 and just one tenth of the air pollutants of coal. Gas turbines can begin generating electricity at full power in just 30 minutes from a cold start, or 10 minutes from warm standby, allowing it to plug any gaps in demand left by intermittent renewables. Its ability to provide many system services such as reserve power and frequency response will see it play an important transition role over the coming decades, until cleaner technologies are able to take over.

Artist’s impression of a Drax rapid-response gas power station (OCGT) with planning permission

Coal is not gone yet, making up 11% of EU’s electricity generation in 2017, but the momentum behind decarbonisation is keeping Europe on track to meet its ambitious emissions target and take the final step away from coal.