Getting electricity safely and efficiently from generators, through power lines and across the country into our devices is a careful balancing act. One of the vital aspects of this is the voltage.

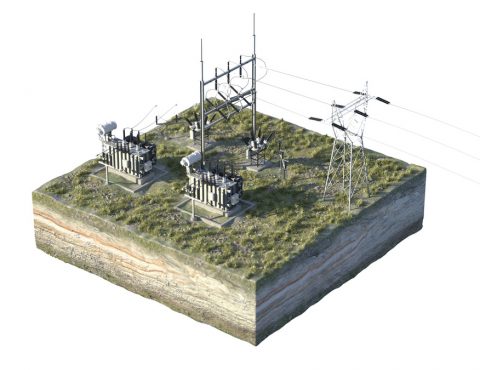

An electrical substation with transformers.

The National Grid’s transmission lines work at a voltage of 400,000 volts (v) and 275,000v, but if electricity were to enter homes at this voltage it would quickly damage anything it powered. Instead, regional distributors deliver electricity into homes at a much lower level of 230v.

Achieving a voltage level that’s safe to use requires stepping it up or down through transformers – huge pieces of electrical grid equipment that use a simple idea to have a big impact.

Why we need transformers

Voltage is like water pressure. Having high voltage transmission lines means the charged electrons that make up electricity are moving very efficiently through the system, with less energy being lost as heat along the way. However, that same ‘pressure’ is too much for just charging a phone. It would likely overload the device’s circuits and leave the user with a smouldering mess.

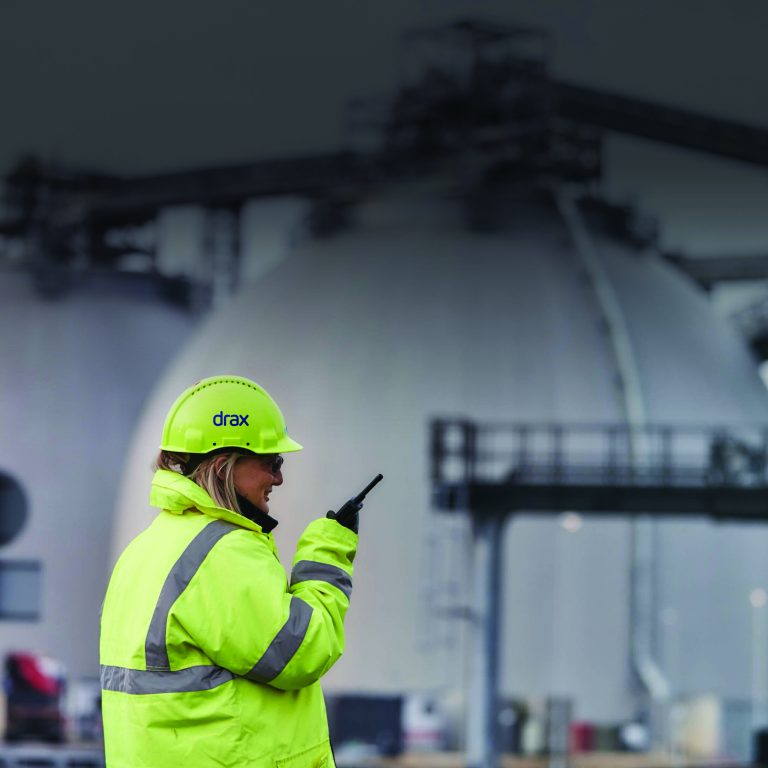

That’s where transformers step in. Electricity is produced at a variety of voltages around Great Britain, depending on different types of generation. In order to send it to where the demand is without losing too much energy as heat along the journey, a transformer attached to large power generators such as Drax’s biomass power plant or Beatrice offshore wind farm increases the voltage to 400,000v or 275,000v. The voltage depends on what part of the national transmission system the power station is connected to.

When the electricity arrives via pylons at a particular region of Great Britain, another transformer brings the voltage down to 132,000v for the regional distribution system. Subsequently, another reduces it to 11,000v in towns and villages, before a final transformer reduces the voltage to a safe 230v for use in homes and businesses.

Keeping the voltage high is useful in preventing energy loss to heat, but it also does something else important to the electricity shooting around the country.

Keeping voltage high to cut down current

If voltage is the water pressure, then current is the actual water particles moving through the pipes. In electrical terms the current is the charged electrons that actually power our lights and devices.

When these electrons travel along the electricity grid’s cables, they face resistance (imagine a partial blockage in a water pipe) this causes some electrical energy to be lost to heat. Getting the right amount of electricity needed around the country means keeping energy loss as low as possible. If the current is lower, fewer charged electrons are bumping into resistance at any one point in the system and less electrical energy is being lost.

Conveniently for the grid, raising the voltage of electricity causes the current to decrease and vice versa. How transformers actually do this is all a matter of coils.

Transformer at Cruachan Power Station

Winding voltage up and down

Transformers work using the principal of electromagnetic induction, something the British scientist Michael Faraday first realised in 1831. He noticed that when a magnet moved through a coil of copper wires, a current flowed through those wires. It’s this same principal that enables spinning turbines to generate electricity today.

Michael Faraday

Similarly, when a current flows through a copper coil wrapped around an iron core, the core becomes magnetic.

Faraday did experiment with running currents through multiple copper coils, but it was scientist and Irish priest Father Nicholas Callan who in 1836 discovered the underlying principal of many of the world’s transformers today. He found if two separate sets of copper wires were wound around each end of an iron core and an electrical current was passed through one of them (the primary winding) then a magnetic field is created that causes an electric current to flow in the secondary winding.

However, things change depending on how many times each wire is wound around the core. If there are more turns in the secondary winding than the primary one, then when a current is induced the voltage increases. When there are fewer turns in the secondary winding than the primary, the voltage decreases.

Callan’s Induction Coil (1845)

Moreover, Father Callan discovered that the increase or decrease in voltage is directly proportional to the number of turns in the windings. So, theoretically, if an electrical current with a voltage of 5v is passed through a primary winding with 10 turns and creates a current in a secondary winding with 20 turns, the voltage will also double, in this case to 10v.

Father Callan’s invention is known as an induction coil, where the two sets of windings share a long, thick iron rod. Since then the transformer has undergone continual revision, optimisation and specialisation for different use cases. However, the underlying principal of using electromagnetic induction to increase and decrease voltage remains the same.

From homes to power stations

One of the most common types of transformers are distribution transformers – the kind often found on utility poles near homes. These transformers perform the final step down from local distribution systems to 230v as the electricity enters homes and businesses.

These often use an iron core that takes the form of a hollow square with windings wrapped around both ends. When a current passes through and magnetises the core it causes it to expand and contract in a process known as magnetostriction, which sometimes causes enough vibration to produce an audible hum.

A transformer being moved from Longannet to Cruachan Power Station in 2019.

In these type of transformers it’s safe for the current to be transferred through the air between the two windings, but when higher voltages are being used, such as at Cruachan Power Station – the biggest pumped storage facility in Scotland – different approaches are needed. Large power station-scale transformers are submerged in a special insulating oil inside a metal container. The oil provides electrical insulation to prevent short circuits while also cooling the core and windings, preventing damage and failure.

Even as the main sources of Great Britain’s electricity change from coal and nuclear power stations to wind farms and solar panels, transformers will remain an essential part of the grid, in getting the right amount of power to where we need it – fast.