Sustainability information

Our Approach

Through our integrated value chain and flexible lower-carbon energy proposition … [Read more]

Achieve together with our people

We are nothing without our people and we take our commitment to provide a safe and healthy workplace … [Read more]

Deliver for our customers

We focus relentlessly on improving our service and developing stronger relationships with our customers … [Read more]

A lower-carbon company

We are committed to enabling a low-carbon future by moving away from coal … [Read more]

Responsible sourcing

Our commitment to sourcing natural resources responsibly is underpinned by our sustainability policy … [Read more]

Reduce our environmental impact

Our responsibility for the environment as a major power supplier goes beyond reducing carbon dioxide … [Read more]

Positive social impact

Our contribution to the community takes many forms, from our direct role in areas … [Read more]

Sustainability case studies

Building a sustainable business

The boundaries between users, suppliers and generators are blurring, writes CEO Will Gardiner … [Read more].

The sustainable development goals

Improved performance has guided our business purpose for over four decades … [Read more]

Commitment to the UNGC

Reporting on the 10 principles of the UN Global Compact … [Read more]

Drax Biomass invests in greenhouse gas efficiencies

Truck dumps, a new train line and use of sawmill residues are helping our own biomass producer … [Read more].

Gamlingay community turbine

Opus Energy works with thousands of renewable electricity generators. Find out more in this purchase power agreement … [Read more]

Partnering to build a Northern Powerhouse

We are passionate about supporting the economy of the North of England … [Read more]

Customer service excellence

Excellent customer service is at the heart of our business … [Read more]

Collaborating for biodiversity protection and enhancement

Drax is committed to protecting biodiversity and playing an active role in habitat enhancement … [Read more]

Drax Biomass creates value in the United States

In many US States, including those in which Drax Biomass operates, there is a system of local taxation … [Read more]

American Tree Farm

The oldest sustainable family woodland system in the US … [Read more]

People strategy

We continue to strengthen, develop and deliver our people strategy across the Group … [Read more]

Listening to local communities

We strive to make a positive impact on local communities to ensure we understand the potential impacts … [Read more]

The Sustainable Biomass Program

The Sustainable Biomass Program’s (SBP) vision is an economically, environmentally and socially sustainable … [Read more]

Working with our suppliers

Working with Pinewells, a supplier of sustainable wood pellets in Portugal … [Read more]

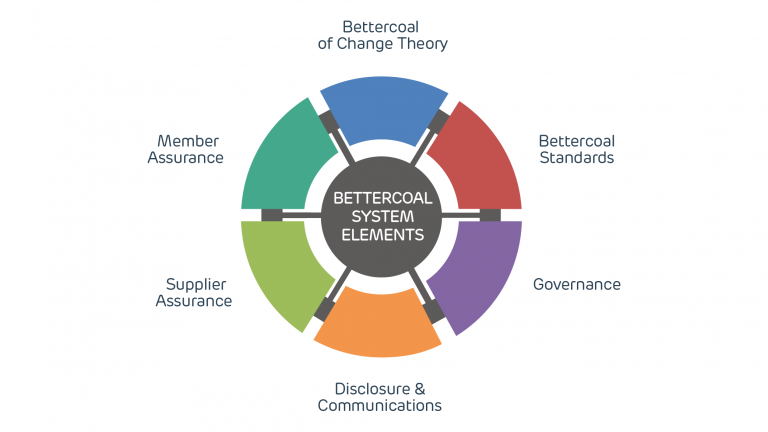

The Bettercoal initiative

Ensuring industry respects people’s rights and makes a positive contribution to the social and economic … [Read more]

Restoring Brickmakers’ Wood

Haven Power employees have worked with the Eden-Rose Coppice Trust to help transform a woodland … [Read more]