Responsible Sourcing

Humans have used wood as a source of fuel for over a million years. Modern biomass power, however, is a far cry from human’s early taming of fire and this is down to constant research and innovation. In fact, today it’s one of the most extensively researched areas in energy and environmental studies.

With biomass accounting for 64% of total renewable energy production in the EU in 2015, the development isn’t likely to stop. Ongoing advancements in the field are helping the technology become more sustainable and efficient in reducing emissions.

Here are seven of the projects, businesses, ideas and technologies pushing biomass further into the future:

When it comes to making biomass as efficient as possible it’s all down to each individual pellet. Improving what’s known as the ‘calorific value’ of each pellet increases the overall amount of energy released when they are used in a power station.

One emerging process aiming to improve this is torrefaction, which involves heating biomass to between 250 and 300 degrees Celsius in a low-oxygen environment. This drives out moisture and volatiles from woody feedstocks, straw and other biomass sources before it is turned into a black ‘biocoal’ pellet which has a very high calorific value.

This year, Estonian company Baltania is constructing the first industrial-scale torrefaction plant in the country with the target output of 160,000 tonnes of biocoal pellets per year. If it’s successful, power stations worldwide may be able to get more power from each little pellet.

Biofuels don’t just come from forest residues. Every day more than two billion cups of coffee are consumed globally as people get themselves caffeinated for the day ahead. In London alone, this need for daily stimulation results in more than 200,000 tonnes of coffee waste produced every year. More often than not this ends up in landfills.

bio-bean aims to change this by collecting used coffee grounds from cafes, offices and factories and recycling them into biofuels and biochemicals. The company now recycles as much as 50,000 tonnes of coffee grounds annually while one of its products, B20 biodiesel, has been used to power London buses. bio-bean also produces briquettes and pellets, which, like woody biomass, can serve as an alternative to coal.

Biogas is often seen as a promising biofuel with fewer emissions than burning fossil fuels or biomass pellets. It’s an area undergoing significant research as it points to another means of creating higher-value products from biomass matter.

The Finnish town of Vaasa is home to the world’s largest gasification plant. The facility is part of a coal plant where co-firing biogas with coal has allowed it to reduce carbon dioxide (CO2) emissions by as much as 230,000 tonnes per year.

As well as reducing emissions, co-firing allows the power plant to use 25% to 40% less coal and when demand is low in the autumn and spring months, the plant runs entirely on biogas. More than that, the forestry residues which are used to produce the biogas are sourced locally from within 100 km of site.

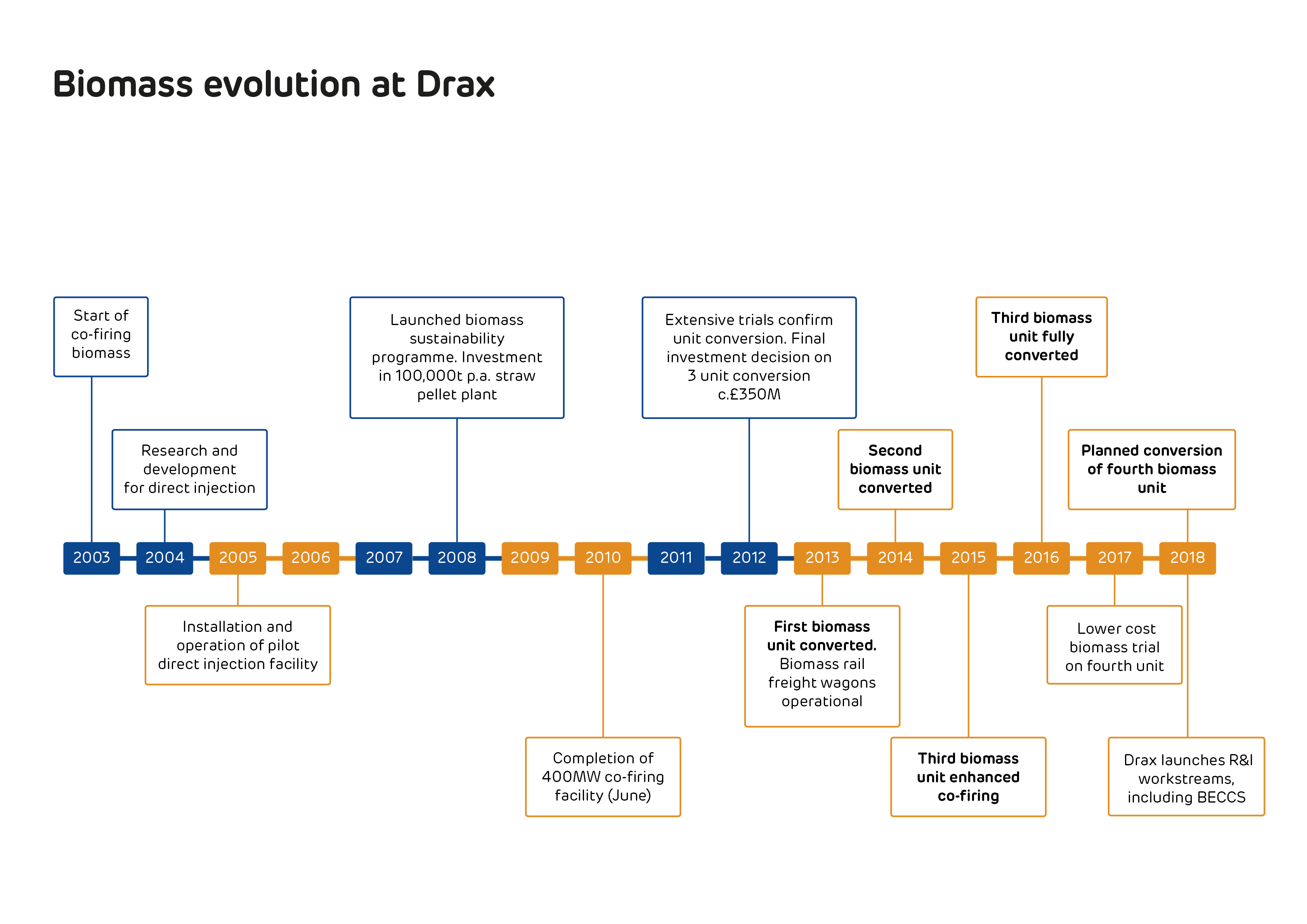

(As part of our transition away from coal, co-firing biomass with that fossil fuel took place at Drax Power Station from 2003 until full unit conversions became a reality in 2013.)

After 44-years, the coal-fired Lynemouth Power Station in Northumberland is the latest UK power producer converting to biomass-fuel. Set for completion this year, the plant will supply 390 MW of low-carbon electricity to the National Grid, enough to power 700,000 homes.

Every new power station conversion poses different challenges as well as the opportunity to develop new solutions, but none are as crucial as the conversion of the materials handling equipment from coal to biomass pellets. While coal can sit in the rain for long periods of time and still be used, biomass must be kept dry with storage conditions constantly monitored and adjusted to prevent sudden combustion.

At Lynemouth the handling of 1.4 million tonnes of biomass annually has required the construction of three, 40-metre high concrete storage silos, as well as extensive conveyor systems to unload and transport biomass around the plant.

Energy and food are both undergoing serious changes to make them more sustainable. Danish startup BioTrans is tackling both challenges by using one of the food industry’s key pain points – wastage – to create energy with its biogas systems.

The company installs systems that collect leftover food from restaurants and canteens and stores it in odour-proof tanks before collecting and turning it into biogas for heating and electricity production. More than just utilising this waste stream, the by-product of the gasification process can also be sold as a fertiliser.

Carbon capture, usage and storage (CCUS) is one of the most important fields in the energy sector today. The technology’s ability to capture CO2 from the electricity generation process and turn it into a revenue source before it can enter the atmosphere means it’s attracting significant investment and research.

Drax is partnering with C-Capture, a company spun out of the University of Leeds’ chemistry department, to trial a new form of CCUS. The pilot scheme will launch in November and aims to capture a tonne of CO2 per day from one of Drax’s biomass units.

C-Capture’s technology could make the process of capturing and storing CO2 less costly and energy intensive. It does this using a specially developed solvent capable of isolating CO2 before being recycled through the system and capturing more.

If the pilot proves successful, the technology could be implemented at an industrial scale, seeing up to 40% of the CO2 in the flue gases from Drax’s biomass units captured and stored. If the technology tested at Drax leads to the construction of a purpose-built carbon capture unit elsewhere, scientists and engineers at C-Capture believe the CO2 captured could exceed 90%.

Back in North Yorkshire, the eventual goal is negative carbon emissions from Drax Power Station – its biomass units already deliver carbon savings of more than 80% compared to when they used coal. And if a new revenue stream can be developed from the sale of the carbon captured then the power produced from biomass at the power station could become even more cost effective.

With thanks to Biomass UK and The European Biomass Association (AEBIOM).

View here

Electricity systems around the world are decarbonising and increasingly switching to renewable power sources. While intermittent sources, such as solar and wind, are the fastest growing types of renewables being installed globally, the reliability and flexibility of biomass and its ability to offer grid stabilisation services such as frequency control and inertia make it an increasingly necessary source of renewable power. According to the International Energy Agency biomass generation is forecast to expand as planned projects come online.

Biomass comes in many different forms. When looking to assess future demand and use, it is important to recognise benefits that different types of biomass bring. Compressed wood pellets are just one small part of the biomass spectrum, which includes many forms of agricultural and livestock residues, waste and bi-products – much of which is currently discarded or underutilised.

Maximising the use of these wastes and residues provides plenty of scope for expansion of the biomass energy sector around the world. The global installed capacity for biomass generation is expected to reach close to 140 gigawatts (GW) by 2026, which will be fuelled primarily by expansion in Asia using residues from food production and the forestry processing industry.

However, the use of woody biomass can also provide many benefits too, such as supplying a market for thinnings, providing a use for harvesting residues, encouraging better forest management practices and generating increased revenue for forest owners.

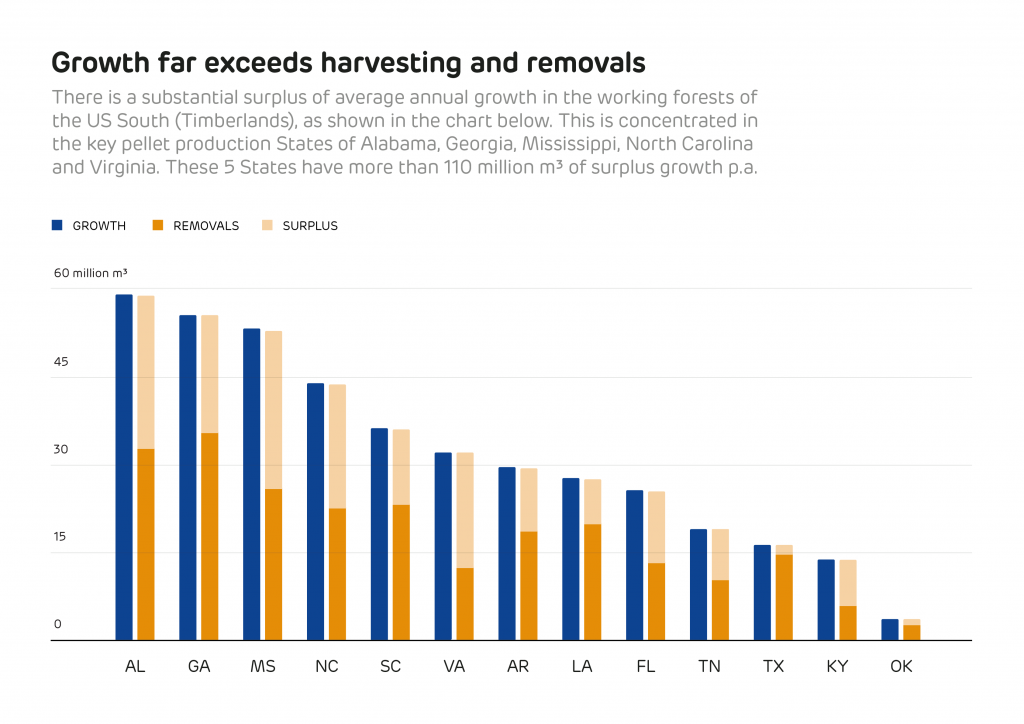

In areas like the US South, traditional markets for forest products have declined, whilst forest growth has significantly increased. According to the USDA Forest Inventory and Analysis (FIA) data, there is an average annual surplus of growth in the US South of more than 176 million cubic metres compared to removals – that’s enough to make around 84 million tonnes of wood pellets a year, from just one supply region.

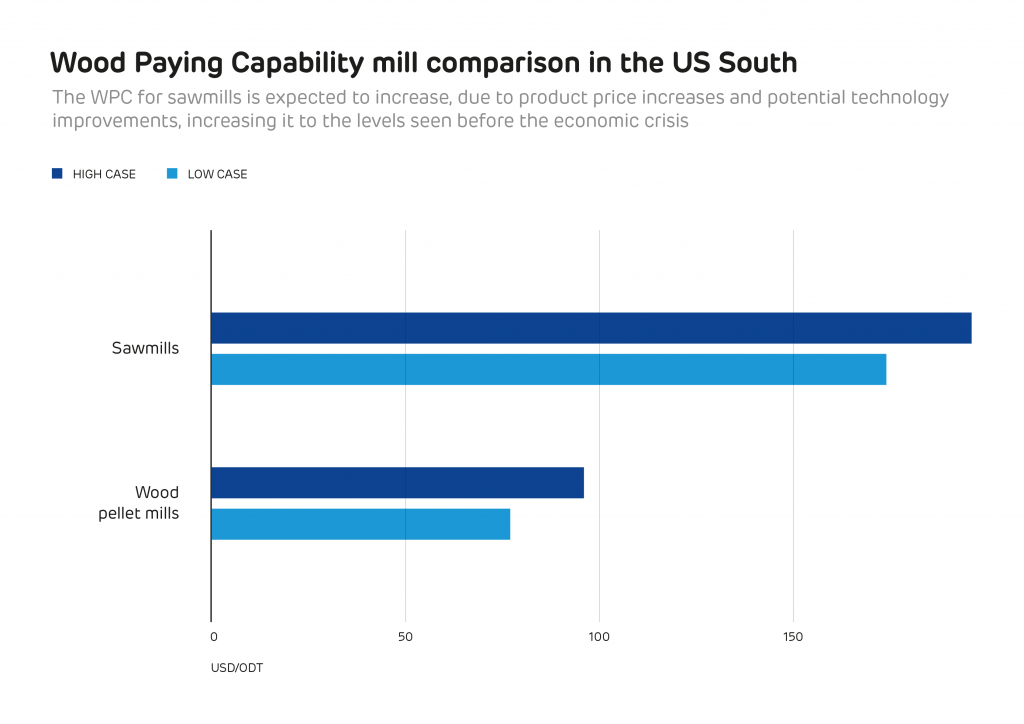

Of course, not all of this surplus growth could or should be used for bio-energy, much of it is suitable for high value markets like saw-timber or construction and some of it is located on inaccessible or protected sites. However, new and additional markets are essential to maintain the health of the forest resource and to encourage forest owners to retain and maintain their forest assets.

In the current wood pellet supply regions for Europe, Pöyry management consulting has calculated that there is a surplus of low grade wood fibre and residues that could make an additional 140 million tonnes of wood pellets each year.

Compressed wood pellets on a conveyor belt

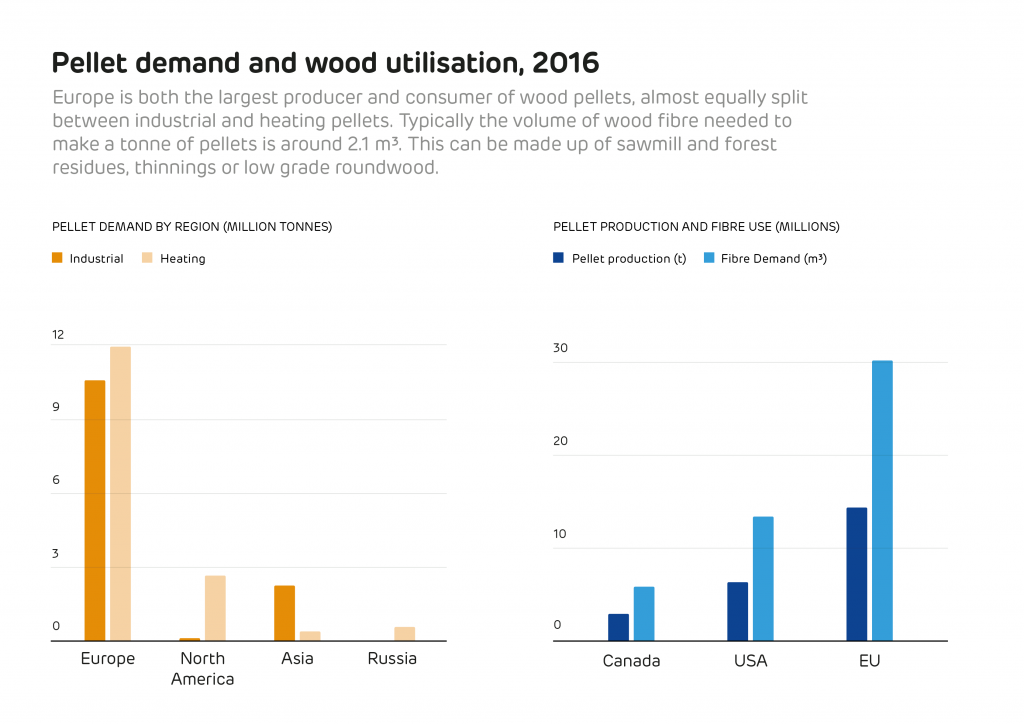

It is also necessary to look at the global production of all wood products to put wood pellet production into context. In 2016 the global production of industrial roundwood (the raw material used for construction, furniture, paper and other wood products) was 1.87 billion cubic metres, while the global production of wood fuel (used for domestic heating and cooking) was 1.86 billion cubic metres[1]. Only around 1.6% of this feedstock was used to make wood pellets, both for industrial energy and residential heat. The total production of wood pellets in 2016 was 28.4 million tonnes, of which only 45% was used for industrial energy[2].

While Forestry consulting and research firm Forisk predicts demand for industrial wood pellets (those used in electricity generation rather than residential heating) will grow globally at an annual rate of 15% for the next five years, reaching 27.5 megatonnes (Mt) by 2023, they are also clear that this growth, in context, will not impact forest volumes or other markets:

‘The wood pellet industry in the US South is not exploding, it is a tiny component of the overall market. Forest volumes in the South in total will continue to grow for decades no matter what bioenergy markets or housing markets do. The wood pellet sector simply and unequivocally cannot compete economically with US pulp and paper mills (80% of pulpwood demand in South) for raw material on a head-to-head basis[3].’

So, while demand for wood pellets is likely to increase over the next 10 years, this increase will be well within the scope of existing surplus fibre. The question, therefore, is can suppliers keep up with this demand? And can they do this while ensuring it remains sustainable, reliable and renewable?

In the short-term, intelligence firm Hawkins Wright estimates global demand will increase by almost 30% during 2018 to reach 20.4 Mt, while Forisk predicts a smaller jump: an almost 5 Mt increase compared to 2017.

Most of this will continue to come from Europe (73% of global demand by 2021, more than 80% in 2018), where projects such as Lynemouth Power Station’s conversion from coal to biomass, as well as five co-firing units in the Netherlands are all set to come online very soon. While smaller in number, Asia is also developing a growing appetite for biomass and in 2018 demand is forecast to grow by 1.98 Mt.

These estimates might paint a picture of a continually soaring demand, but Forisk’s forecast actually expect this growth to plateau, levelling off around 2023 at 27.5 Mt. Hawkins Wright expects a similar slow down, forecasting manageable growth of under 15% between 2023 and 2026.

A forestry specialist at Drax Group, believes this plateau could come even sooner.

“Current and future forecasts in industrial wood pellet demand are based on a series of planned conversions and projects coming online,” he explains.

“But once these projects are active, demand in Europe will likely plateau around 2021 and then gradually reduce as various EU support schemes for industrial biomass come to an end. Any long term use of biomass is likely to be based on agricultural residues and wastes.”

But even with this expected slowdown, the biomass demand of the near future will be substantially higher than it is right now. So, the question remains, can suppliers meet the need for biomass pellets?

Meeting this growing demand depends on two factors: sufficient raw materials and the production capabilities to turn those materials into biomass pellets.

In today’s market, there’s no shortage of raw materials and low grade fibre. Instead, what could cause challenges is the production of pellets.

Hawkins Wright reports the capacity for global industrial pellet production was roughly 21.4 Mt a year at the end of 2017 and will increase by a further 3 Mt by 2019 as facilities currently under construction reach completion.

It means that to meet even Forisk’s conservative 27.5 Mt prediction by 2023, pellet production needs to increase. However, Drax’s forestry specialist points to the three to four years needed to complete pellet facilities and the relatively short period of time financial support programmes will remain in place as something that could lead to a slowdown in new plants coming online. Instead, he says, expansions of existing plants and the increased use of small-scale facilities will become crucial to increasing overall production.

However the biomass market changes and develops, it remains critical that proper regulation is in place, efficiencies are found and that technological innovation continues within the forestry industry so forests are grown and managed sustainably.

As we move into a low-carbon future we know that biomass demand will increase. But for this to be truly beneficial and sustainable we need to ensure we are not only meeting the demand of today but also of tomorrow, the day after tomorrow and beyond.

[1] Source: FAOSTAT

[2] Source: Hawkins Wright, The Outlook for Wood Pellets, Q4 2017

[3] https://www.forisk.com/blog/2015/10/23/nibbling-on-a-chicken-or-nibbling-on-an-elephant-another-example-of-incomplete-and-misleading-analysis-of-us-forest-sustainability-and-wood-bioenergy-markets/

We have increased the capacity at Drax Biomass Amite and Morehouse pellet plants to increase capacity and made them more greenhouse gas (GHG) efficient. Central to the projects was the addition of storage silos and handling equipment to allow increased use of dry shavings and other mill residuals. The developments included the addition of an extra truck dump at each facility to allow delivery of increased volumes of these feedstocks.

Use of mill residuals and dry shavings reduces the energy required to make a pellet, as such material does not need to be de-barked, chipped and re-sized in the same way as roundwood. Some of the material has a low moisture content and is therefore able to enter the process after the dryer, which effectively increases the capacity of each plant. This drives down the average GHG emission per tonne of pellets produced. A key measure of this is the KWh of electricity per tonne of pellets, and we saw this reduce by about 10% in the final months of the year compared with the start of the year, with further savings anticipated.

LaSalle BioEnergy in Louisiana

At LaSalle, a significant amount of our investment is going into allowing pellets to be transported to the port by rail, rather than truck. For the 250 km trip to Baton Rouge, a significant carbon saving compared to trucks will be achieved when LaSalle reaches its capacity of 450,000 tonnes per year. Moving pellets by rail should start in the next year.

In 2013, Drax co-founded the SBP together with six other energy companies.

SBP builds upon existing forest certification programmes, such as the Sustainable Forest Initiative (SFI), Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC). These evidence sustainable forest management practices but do not yet encompass regulatory requirements for reporting greenhouse gas (GHG) emissions. This is a critical gap for biomass generators, who are obligated to report GHG emissions to European regulators.

There is also limited uptake of forest-level certification schemes in some key forest source areas. SBP is working to address these challenges.

SBP certification provides assurance that woody biomass is supplied from legal and sustainable sources and that all regulatory requirements for the users of biomass for energy production are met. The tool is a unique certification scheme designed for woody biomass, mostly in the form of wood pellets and wood chips, used in industrial, large-scale energy production.

SBP certification is achieved via a rigorous assessment of wood pellet and wood chip producers and biomass traders, carried out by independent, third party certification bodies and scrutinised by an independent technical committee.

Biomass is playing an important role in moving the UK away from coal. At Drax Power Station, in the form of compressed wood pellets, biomass is already supplying roughly 17% of Great Britain’s renewable power.

But more than just being a low carbon replacement for fossil fuel generation, it is also crucial in maintaining the stability of the power network. Among renewable sources of power, biomass is unique in being able to provide the same range of ancillary services that can be provided by coal power stations – such as frequency control and inertia. This inherrent flexibility is vital in maintaining stability on Britain’s high voltage transmission system. Wood pellets can also reliably generate power, helping to fill in the gaps left by intermittent renewables when the wind doesn’t blow and the sun doesn’t shine and avoiding reliance on diesel, coal and gas.

However, for the UK and the wider global environment to reap the maximum benefits from biomass, it must be produced sustainably. More than this, its supply chain must be low in emissions so that clear savings can be made versus power generation with fossil fuels.

To ensure this, the use of biomass is regulated in the UK under EU Timber Regulations and the Renewables Obligation (RO). But further guidelines are set to be introduced as part of the European Parliament’s update to the Renewable Energy Directive (RED), which will specify criteria for all biomass.

There is a clear need for this, but for these to be truly successful they need to be based on a set of robust key principles. A new report by Drax outlines seven of these which can ensure sustainable biomass usage in the future.

The sustainability of the forests from which biomass is sourced is key to ensuring its usage has a positive impact on the environmental, social and economic health of that supply region.

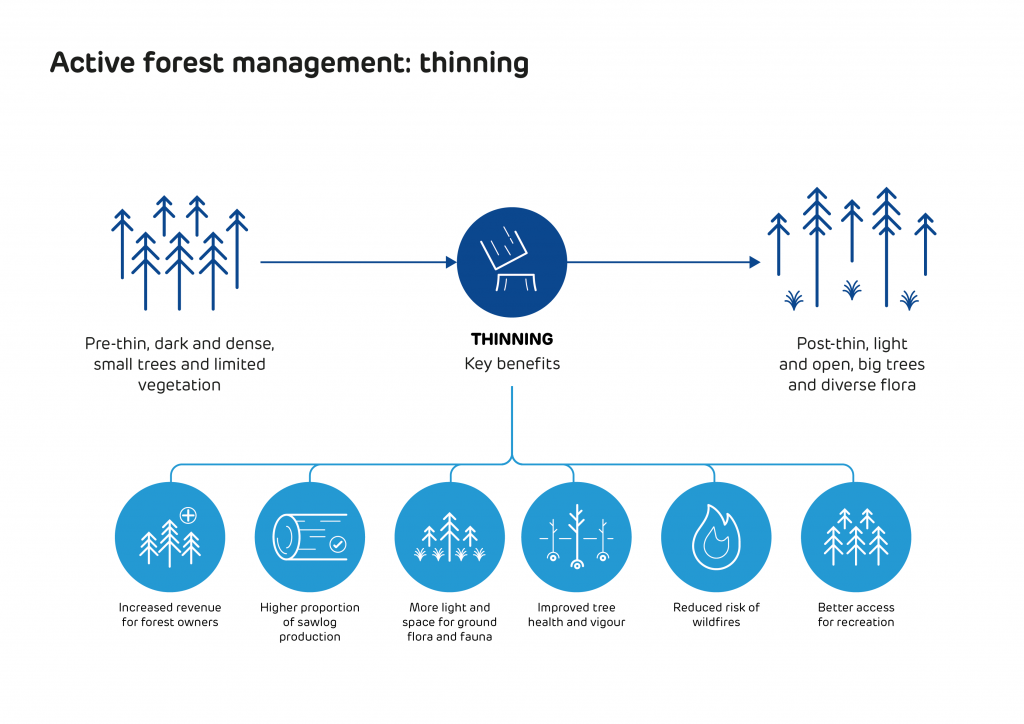

For example, a properly managed forest can boost carbon stock as the younger, faster growing trees that are replanted after felling absorb more CO2 than older, over-mature trees. Thinning operations also increase the growth of the biggest and best trees, ensuring more carbon is stored in longer term solid wood products.

Generators should be able to demonstrate they are avoiding biomass sourced from higher-risk areas where extracting biomass could cause long-term carbon stock decreases in soils or ecosystems, as well as other factors such as biodiversity loss, soil erosion or depletion of water sources.

Feedstocks, the raw materials turned into biomass pellets, must come from sustainable sources and avoid protected and sensitive sites that could be considered a risk.

In 2016 around 40% of all feedstock supplied to Drax originated as a sawmill residue. Processes such as thinning also serve as a source of biomass feedstock, while also benefitting the overall health and quality of the forest. Thinning a semi mature stand of trees allows the forest owner to maximise the production of higher value saw-timber trees, storing more carbon and generating more stable revenue streams. Having a variety of wood products markets from saw logs through to biomass incentivises land owners to maintain healthy forests and reduces the risk of conversion of forest to agriculture or urban development.

To understand the effectiveness of biomass sustainability policy, carbon savings need to be measured.

Factors such as fossil fuel substitution and the emissions associated with harvesting, processing and transporting biomass are relatively straightforward to measure.

Unlike coal or oil, which will eventually run out, more trees can be planted, grown and harvested.

That said, there is a natural limit to the amount of biomass available on the planet, and so it should not be considered an infinite resource. This is why it’s crucial biomass is sourced from sustainable forests managed following set guidelines. In short, to ensure biomass truly is sustainable, it is essential that working forests are actively managed and maintain or increase productivity.

One of the major advantages of biomass over other renewable sources is its potential to help the UK rapidly adapt to meet the EU target of achieving 27% of final energy consumption from renewables.

The fastest way for biomass to make an impact to the UK’s carbon emissions is through converting coal power stations to biomass, as is the case at Drax Power Station.

This repurposing of existing facilities not only offers rapid adoption of renewable energy, but also the ability to provide vital ancillary services other renewable sources can’t.

Quickly deploying biomass solutions in this manner will serve to help it become an established part of the energy system as it continues to decarbonise.

Globally, there are substantial amounts of forest residue and forestry industry by-products that currently go unused.

Biomass should be sourced from regions where the largest surpluses exist and the forest carbon balance can be maintained. To enable this to function effectively on a global scale, trade restrictions should be avoided.

Pelletisation offers one of the most efficient ways for this raw material to be used by making it safe, cost-efficient and low-carbon to transport around the world.

These principals are tried and tested by Drax and known to protect forests and ecosystems, as well as optimise supply chains to ensure carbon emissions are kept to a minimum. Ultimately, Drax’s experience in sustainably using biomass serve as a guide for other producers and governments to quickly decarbonise energy systems.

One of the best ways to guarantee biomass is sourced sustainably is by introducing third-parties and official guidelines that generators and suppliers can work with.

In Europe, forest level management certification schemes can act as an effective indicator that forests are managed in accordance with the guidelines laid out by Forest Europe. Outside of Europe, where Drax sources most of its biomass, independent, third part auditors can ensure the UK’s stringent criteria are being met on the ground.

Read the full report: The 7 Principles of a Sustainable Forest Biomass Policy – Proven to Work

Roughly 750 million acres of the US is covered in forestland – an area nearly 12 times the size of the UK. Approximately two-thirds of that land is working timberland, producing wood used for construction and furniture. In short, US forestry is a massive industry.

Enviva is the world’s largest wood pellet producer and biggest biomass supplier to Drax Power Station, but in the context of the US forestry industry in which it operates, Enviva does things differently.

“We’re leading the industry in sustainability and transparency in our sourcing practices,” says Jennifer Jenkins, Vice President and Chief Sustainability Officer at Enviva. “We’ve created unique tracking systems and we conduct science-based sourcing, both of which encourage sound forest stewardship.”

Specifically, Enviva draws on best practices to make decisions about which areas it sources from and how it protects the areas it doesn’t.

A bottomland forest is an area of low-lying marshy area near rivers or streams that can be home to unique tree and wildlife species. These forests are flooded periodically and they can be ecologically important. However, they’re also a part of south-eastern America’s working forest landscape.

In fact, Enviva sources 3-4% of its wood from these areas, but only where harvesting improves the life of the forest. For example, in some cases, harvesting mimics naturally occurring storms, clearing the canopy so young seedlings and forest floor species thrive. More than that, harvesting can also help keep forests as forests.

“In the areas where we work, one of the biggest threats to forests is being converted to another use – specifically to developed or agricultural land,” explains Dr. Jenkins. “Our goal is to keep forests as forests. We want to preserve those with the highest risk of being converted for another use.” If landowners can gain a steady income from regular harvests, they’re likely to keep their land as working forests.

However, this is only true for carefully assessed forests where harvesting is deemed safe. Any land that doesn’t meet Enviva’s set of strict criteria means Enviva won’t source from it – it can simply walk away. The landowners, on the other hand, don’t have that luxury.

“Isn’t it our responsibility to provide another option for a landowner who might not want to facilitate a harvest?” asks Dr. Jenkins. “Maybe they recognize its value. Maybe they would prefer to conserve it instead. In recognition of our responsibility, we made a commitment.”

Enviva’s commitment was to partner with the US Endowment for Forestry & Communities to set up the Enviva Forest Conservation Fund, a $5 million, 10-year programme designed to protect tens of thousands of acres of sensitive bottomland forests in the Virginia-North Carolina coastal plain.

It works by inviting submissions from projects looking to protect areas of high conservation value. Last year it awarded its first round of funding to four projects. More recently, in June 2017, the Enviva Forest Conservation Fund announced a total of $500,000 to go toward a second round of projects with partners such as Ducks Unlimited, an organization which – with the grant – plans to acquire more than 6,000 acres of wetlands to operate as a public Wildlife Management Area.

The Fund follows a history of proactive sustainability programmes, including a strict supplier assessment process and the company’s Track & Trace tool, a one-of-a-kind publicly-accessible system that tracks every ton of primary wood Enviva purchases back to the forest from which it was sourced. It is entirely transparent and is a testament to Enviva’s commitment to sustainability and doing things differently.

As Dr. Jenkins explains, this approach stems back to the origins of the company in 2004: “As a company that makes wood pellets, Enviva’s reason for being is to help lower greenhouse gas emissions. An emphasis on sustainability has always been a part of Enviva’s DNA.”

A study on the historical trends in the forest industry of the US South, carried out by supply chain consultancy Forest2Market, and commissioned by Drax Group, the National Alliance of Forest Owners and the U.S. Endowment for Forestry and Communities, found that over the last 60 years, as demand for forestry products has increased, the productivity of the area’s forests has increased too. In short, the more we’ve come to use them, the more forests have grown.

A forest is not like a mine – there is not a finite amount of wood in the ground that disappears when it is extracted, never to return. Forests are a renewable resource that can be replanted, improved, and harvested for as long as the land is managed responsibly.

What’s more, landowners have a strong financial incentive to not only maintain their holdings but to improve their productivity – after all, the more of something you have, the more of it you have to sell. It is an economic incentive that works.

The Forest2Market report found that increased demand for wood is statistically correlated with more annual tree growth, more wood volume available in the forest, and more timberland.

For example, between 1953 and 2015, tree harvests increased by 57%, largely driven by US economic growth and increased construction. Over the same period, annual wood growth increased by 112%, and inventory increased by 108%. In total, annual growth exceeded annual removals by 38% on average.

Annual forest growth in the US South increased from 193 million cubic metres in 1953 to 408 million cubic metres in 2015. Inventory increased from 4 billion to 8.4 billion cubic metres.

The forest products industry funded private-public research projects to enhance the quality and performance of seedlings and forest management practices to ensure a stable supply of wood. Because of these efforts, landowners saw the value of active management techniques, changing their approach to site preparation, fertilization, weed control, and thinning, and the use of improved planting stock. Healthy demand made it easy for landowners to take a long-term view, investing in more expensive management practices up front for greater returns in the future. And the results were extraordinary: seedlings established in the last 20 years have helped plantations to become nearly four times as productive as they were 50 years ago.

Markets for wood have changed over the last two decades, precipitated by decreased demand for writing paper and newsprint, increased demand for absorbent hygiene products and containerboard and increased demand for biomass. These changes in demand have not impacted the way that landowners manage timberland, however. As sawtimber (the largest trees in the forest) remains the most valuable timber crop, it also remains the crop the landowners want to grow. Pulpwood is harvested from the forest only when the forest is being thinned to create optimal conditions for growing sawtimber or when sawtimber is harvested and the forest is being cleared for replanting.

Pellet production has expanded rapidly in the US South, though its overall footprint is still small in comparison to more traditional forest product industries.

In some local wood basins, however, like the one surrounding Bastrop, Louisiana (the location of one of Drax’s US production facilities), the use of biomass to create pellets has filled a gap left by the closure of an 80-year old paper mill. Drax’s decision to locate in this area is integral to supporting forest industry jobs and landowners who carefully consider local demand when deciding whether to continue growing trees.

According to Tracy Leslie, Director of Forest2Market’s biomaterials and sustainability practice, “As history has shown, forests in the US South have benefitted from increased demand for all types of wood. The rise of the pulp and paper industry did not detract from landowner objectives to maximize production of higher value sawtimber nor did it result in a shift in focus to growing only pulpwood. This new demand did, however, provide landowners with important interim and supplemental sources of income. Forest2Market’s research shows that an increase in demand for pellets will have the same effect, incentivizing landowners to grow and re-grow forests, increasing both forest inventory and carbon storage.”

Not only does demand for forest products increase the productivity and carbon storage of forests and provide an incentive for landowners to continue growing trees, but it also helps counter factors that irrevocably destroy this natural resource. The real threat to forests in the US is not demand for wood, but urbanisation. Nearly half of all US forestland that converted to another use between 1982 and 2012 was cleared for urban development.

Commercial forestry protects forested lands from development; between 1989 and 1999, just 1% of managed pine plantations in the US South were cleared for non-forest development compared to 3% of naturally-regenerated forest types.

Urbanisation, not the forest products industry, places the most pressure on forests in the US South. Forest2Market’s findings demonstrate that demand associated with healthy timber markets promotes the productivity of forests and mitigates forest loss by encouraging landowners to continue to grow, harvest, and regenerate trees.

Read the full report: Historical Perspective on the Relationship between Demand and Forest Productivity in the US South. An At A Glance version plus an Executive Summary are also available as a separate documents.