- Innovative biotech start-up, Deep Branch Biotechnology, is partnering with Drax Group on a new bioenergy carbon capture usage and storage (BECCUS) pilot which could help reduce emissions from the agricultural sector

- Carbon dioxide will be used to create protein which could replace soy and fishmeal, the main components in fish and livestock feeds

- The project aims to help meet the anticipated increase in global demand for meat products

- Global markets for single cell proteins could be worth £9bn by 2023

Drax is working with biotech start-up Deep Branch Biotechnology to explore the feasibility of using the power station’s carbon dioxide emissions to make proteins for sustainable animal feed products.

Deep Branch Biotechnology, a leading tech start-up based at Nottingham University, will place a pilot plant within Drax’s Carbon Capture Usage and Storage (CCUS) Incubation Area at its power station in North Yorkshire.

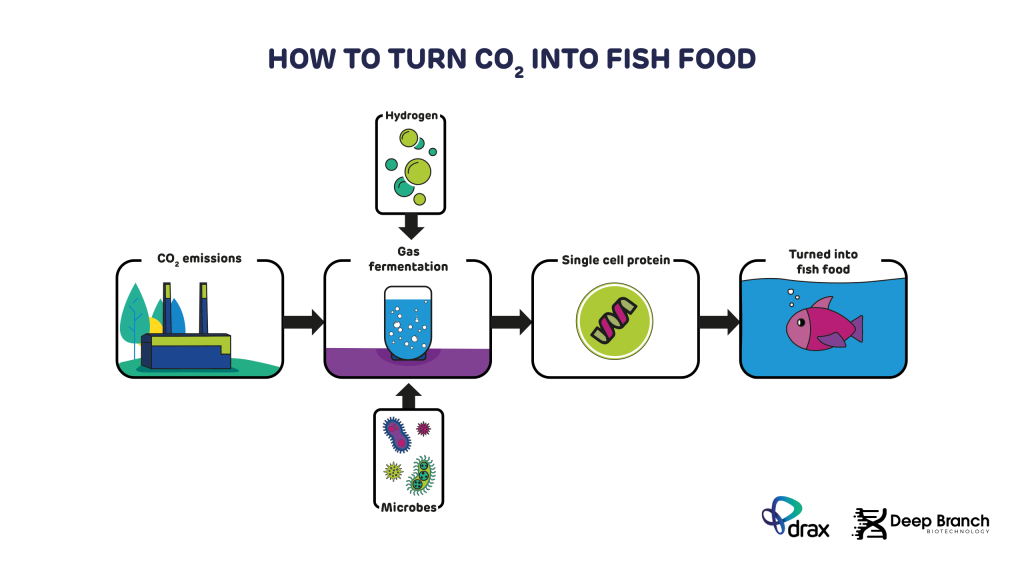

It will extract flue gases from the power station’s renewable electricity generation to feed to microbes, which can make single cell proteins for use in fish food and other sustainable animal feeds.

Drax Group CEO Will Gardiner said:

“By giving partners like Deep Branch Biotechnology access to our CCUS Incubation Area we can test emerging technologies and explore their potential in delivering for both the climate and the economy.

“We want to create a cleaner environment for future generations whilst generating new jobs and export opportunities for British businesses. Technologies like this could enable some of our more difficult to decarbonise sectors, like agriculture, to make positive changes to address the climate crisis.”

Drax Power Station is the biggest renewable electricity generator in the UK and the largest decarbonisation project in Europe having converted two thirds of the plant to use sustainable biomass instead of coal.

It is exploring the feasibility of using BECCUS technologies to help further reduce its emissions and contribute towards the UK meeting its climate targets. This is Drax’s first incubation project exploring a market for carbon dioxide. The power station has also held discussions with the British Beer and Pub association about the possibility of captured CO2 being used to carbonate drinks.

Drax Group CEO Will Gardiner (second right) accompanied Energy and Clean Growth Minister Claire Perry in a visit to the Drax Power Station BECCS pilot project in November 2018. Download graphic in high-res

A dedicated Incubation Area has been created at the power station to give other technology companies the opportunity to test their processes on its carbon dioxide.

Chris Skidmore, Minister for Energy and Clean Growth, said:

“Carbon capture, usage and storage technologies are not only putting fizz in our drinks but feeding fish too.

“As we move towards net zero emissions and end our contribution to global warming, innovative projects like this will help reduce agricultural emissions and meet increasing demand for animal feed, demonstrating the enormous global potential CCUS has to tackle climate change.”

Peter Rowe, Deep Branch Biotechnology CEO, explained that the method they have developed for producing proteins from CO2, relies on an edible microbe that consumes carbon dioxide.

When fed carbon dioxide, the microbes grow and reproduce, enabling them to be continually harvested for protein whilst maintaining a growing culture. Under optimal conditions, up to 70 per cent of the material produced is protein.

Download graphic High Res (no logo) High Res (with logo)

The benefits of this process over other carbon capture technologies is that the CO2 does not need to be separated from the power station’s flue gases before being fed to the microbes.

Peter said:

“Meat production is set to double by 2050 as global populations increase, but using existing methods of producing animal feeds to meet this growing demand is completely unsustainable.

“The technology we’ve developed is an exciting solution. We can convert up to 60-70% of CO2 into protein, helping to both minimise the greenhouse gases released into the atmosphere during power generation and other industrial processes, whilst producing protein for animal feeds which will help reduce the impact of agricultural sectors on the environment as well.”

The USA is the world’s biggest soy producer, producing one third of global supply, and uses 97% to produce animal feed. Over 60% of cereals grown globally are being used in animal feeds along with 20 million tonnes of ocean-caught fish.

Concerns about overfishing have seen the aquaculture (farmed fish) industry boom, yet this industry uses more than 15% of ocean-caught fish for feed, in the form of fishmeal.

The new proteins created using the Deep Branch biotechnology could help reduce the quantities of fish removed from the oceans. This not only minimises the impact on ecosystems, but decreases the amount of carbon dioxide in the atmosphere, mitigating the harmful effects of climate change.

The Deep Branch pilot will get underway in the autumn, when a demonstration plant will be installed within the Drax CCUS Incubation Area.

It aims to capture enough CO2 to produce 100kg of protein to be used to create feedstocks for fish and livestock. The protein generated from the project will be used in a trial project with a major feed producer.

If successful, Deep Branch Biotechnology plans to build a larger production facility by 2020 so it can produce several tonnes of protein per year.

ENDS

Media contacts:

Ali Lewis

Drax Group Head of Media & PR

E: [email protected]

T: 07712670888

Jessica Gorton

Drax Group Press Officer

E: [email protected]

T: 07712677177

Deep Branch Biotechnology

[email protected]

Editors’ note:

- Drax announced in February that is had started to capture carbon dioxide from its first Bioenergy Carbon Capture and Storage (BECCS) pilot project using technology developed by Leeds University spin-out company C-Capture.

- This is the first-time carbon dioxide has been captured from the combustion of a 100% biomass feedstock anywhere in the world. If the pilot can be scaled up to deliver negative emissions, Drax Power Station would be helping to remove the gases that cause global warming from the atmosphere at the same time as electricity is produced.

- Since starting its innovative BECCS pilot project Drax has been talking to several industries about using its CO2 in their processes. This could be to produce concrete, within the food and drinks industry or creating synthetic fuels to use in hard-to-decarbonise sectors like aviation.

- Drax announced in May it had signed a memorandum of understanding with Equinor and National Grid Ventures. The three energy companies will work together to explore how a large-scale carbon capture usage and storage (CCUS) network and a hydrogen production facility could be constructed in the Humber in the mid-2020s.

- The Committee on Climate Change’s Net Zero report states that BECCS could generate up to 173 TWh of electricity by 2050, capturing up to 51 Mt CO2 – around half of the remaining carbon in the economy that the UK will need to capture to become ‘net zero’.

- Today Drax is capturing a tonne of carbon dioxide a day from its C-Capture BECCS pilot – once scaled up it could be capturing up to 16 million tonnes of carbon a day from its four biomass generating units.

- The agricultural sector was one highlighted by the Committee on Climate Change in its Net Zero report, as being too slow to make progress in reducing emissions.

- The UN’s Food and Agriculture Organisation has found that around a third of all global cropland is used to grow animal feed, in the form of soy.

- Around 15 per cent of all fish caught globally are turned into feed for commercial fisheries, according to analysis by the UK’s Sea Fish Industry Authority.

- Using bacteria to make protein for animal feed was first considered in the 1970s. It is now more economically viable as producing fishmeal powder from milling and drying fish parts has become more expensive and has not kept up with growing human demand for fish.

About Deep Branch Biotechnology: Deep Branch Biotechnology’s mission is to transform the polluters of today into the producers of tomorrow. Their technology removes carbon dioxide directly from emissions, generating single cell protein, a clean and sustainable alternative to soy and fishmeal, the conventional protein sources for livestock and aquaculture feed. They were recently recognised in Forbes’ European 30 Under 30 Manufacturing & Industry 2019.

For more information visit www.deepbranchbio.com

About Drax

Drax Group’s ambition is to enable a zero carbon, lower cost energy future. Its 2,600-strong staff operate across three principal areas of activity – electricity generation, electricity sales to business customers and compressed wood pellet production.

Power generation:

Drax owns and operates a portfolio of flexible, low carbon and renewable electricity generation assets across Britain. The assets include the UK’s largest power station, based at Selby, North Yorkshire, which supplies five percent of the country’s electricity needs.

Having converted two thirds of Drax Power Station to use sustainable biomass instead of coal it has become the UK’s biggest renewable power generator and the largest decarbonisation project in Europe.

Its pumped storage, hydro and energy from waste assets in Scotland include Cruachan Power Station – a flexible pumped storage facility within the hollowed-out mountain Ben Cruachan. It also owns and operates four gas power stations in England.

B2B supply:

Drax owns two B2B energy supply businesses:

- Haven Power, based in Ipswich, supplies electricity and energy services to large Industrial and Commercial sector businesses.

- Opus Energy, based in Oxford, Northampton and Cardiff, provides electricity, energy services and gas to small and medium sized (SME) businesses.

Pellet production:

Drax owns and operates three pellet mills in the US South which manufacture compressed wood pellets (biomass) produced from sustainably managed working forests. These pellet mills supply around 20% of the biomass used by Drax Power Station in North Yorkshire to generate flexible, renewable power for the UK’s homes and businesses.

For more information visit www.drax.com/us