Key takeaways:

- Removing carbon from the atmosphere is urgent if we are to meet global climate targets

- The U.S.’s commitment to supporting carbon removal technologies creates an opportunity for new bioenergy with carbon capture and storage (BECCS) power stations

- The market for carbon credits is gaining increasing credibility and verification, making it a source of financing for ambitious decarbonization projects

- Carbon markets are needed now to make investment into vital removals projects possible in the U.S. and globally

After a summer of soaring temperatures across the Northern Hemisphere, the global nature of climate change is more obvious than ever. Forest fires around the world in 2021 resulted in double the loss of tree cover than in 2001, while today more than 2.3 billion people face water stress from drought. It’s clear that the action we take to help tackle the global climate emergency must be international too.

We believe that carbon dioxide (CO2) removals will be crucial in addressing this global challenge. Experts and governments agree that in addition to economy-wide decarbonization, removing carbon from the atmosphere is critical to meeting the goal of net zero CO2 emissions by mid-century. The IPCC says 10 billion tons per year of removals will be needed in 2050 for the world to get to net zero. That’s a huge step up from the 40 million tons captured globally in 2021, but also a significant investment opportunity.

Our ambition is to remove 4 million tons of CO2 through bioenergy with carbon capture and storage (BECCS) outside the UK per year, while generating renewable, baseload electricity and supporting healthy, sustainable forests.

The likely contender for our first location? The United States. We already operate in communities across the U.S. South, employing more than 1,200 people in our sustainable biomass pellet production. Now we are preparing to build a new BECCS power station in the region.

It’s clear to us that the U.S. is an ideal market for BECCS with its long-running sustainable forest industry and range of suitable sites for permanent CO2 storage. We see the country’s efforts to retire coal by 2030 and commitment to innovation as an opportunity to build one of the largest carbon removal projects in the U.S. Our first plant could be capable of permanently removing 2 million tons of carbon from the atmosphere a year, while also generating 2-terawatt hours of 24/7 renewable power.

The U.S.’s newly legislated commitment to tackling climate change through the Inflation Reduction Act, as well as the Department of Energy’s National Renewable Energy Lab recent scenario planning for ‘100% clean electricity system’ are establishing it as the leading market to deploy new environmental technologies. And a new frontier for permanent, high-quality emissions removals.

The need for high quality, permanent emissions removals

A net zero future is only possible through the wide-spread implementation of high-integrity, carbon removals. BECCS offers this by combining low carbon, renewable biomass power generation with carbon capture technology and secure, permanent carbon sequestration.

BECCS works by generating renewable electricity using biomass sourced from sustainably managed forests that absorb CO2 as they grow. CO2 released in the generation process is captured and stored, permanently and safely, in geological rock formations. The overall process removes more CO2 from the atmosphere than it emits, resulting in negative emissions.

This allows us to offer decarbonizing industries high-quality carbon removals credits. Given the scale of CO2that must be removed from the atmosphere and the importance for countries and companies around the world to reach net zero, I believe this market for verified CO2 removal credits is a trillion-dollar opportunity.

Voluntary carbon markets have historically suffered from a lack of sustained and reliable investment due to fluctuating market prices and varying quality of the carbon credits they contain. However, increased oversight from investors, NGOs and independent bodies is encouraging credibility and integrity, prompting sustained adoption by businesses.

Drax Group CEO Will Gardiner [click to view/download]

We’ve demonstrated the growing appetite for carbon removals by signing the worlds largest carbon removals deal to date at New York Climate week. The agreement with Respira, an impact-driven carbon finance business, will allow it to purchase 400,000 metric tons of CO2 removals (CDRs) a year from our North American operations. This would enable other corporations and financial institutions to achieve their own CO2 emissions reduction targets, by purchasing CDRs from Respira.

Deals like these make voluntary carbon markets a more effective means of reducing net CO2 emissions by securing commitments and driving investment in projects that deliver independently verified, high-quality emissions reductions. As the global economy works towards its net zero targets, CO2 removals will be crucial in reducing the still dangerously high levels of carbon in our atmosphere today.

BECCS stands to be a powerful tool in a net zero future as the only technology capable of delivering both high quality, permanent carbon removals, while also delivering baseload renewable power. The ability to generate power with negative emissions will be crucial for increasingly electrified economies, as they move away from fossil fuels.

The potential for the U.S.

Driven by a dynamic mix of markets, investors and engaged consumers, some of the most prominent U.S. companies are pledging to reach net zero, investing in 24/7 renewable power and other means to do so.

Technology companies like Alphabet, Apple, and Microsoft have laid out ambitious plans to decarbonize operations, supply chains, and even remove historic emissions. Other organizations, like the First Movers Coalition, include U.S. companies from a range of sectors committing corporate purchasing power to solving difficult decarbonization challenges.

This industry readiness is increasingly backed up by legislative policy action. The recent Inflation Reduction Act substantially increases the availability of the 45Q tax credit for carbon capture and storage projects, increasing their value from $50 a ton of carbon removals to $85 per ton, helping to further support the business case needed to deploy technologies like BECCS.

We believe the U.S. is on the right track to create a market in which BECCS can thrive. The Department of Energy’s National Renewable Energy Lab recent ‘100% clean electricity system’ report includes BECCS in three of the four possible scenarios explored. It forecasts the US will need between 7-14GW of installed BECCS capacity by 2035 to achieve an electricity system with net zero CO2 emissions. That equates to removals of approximately 55-120 Mt CO2 per year by 2035.

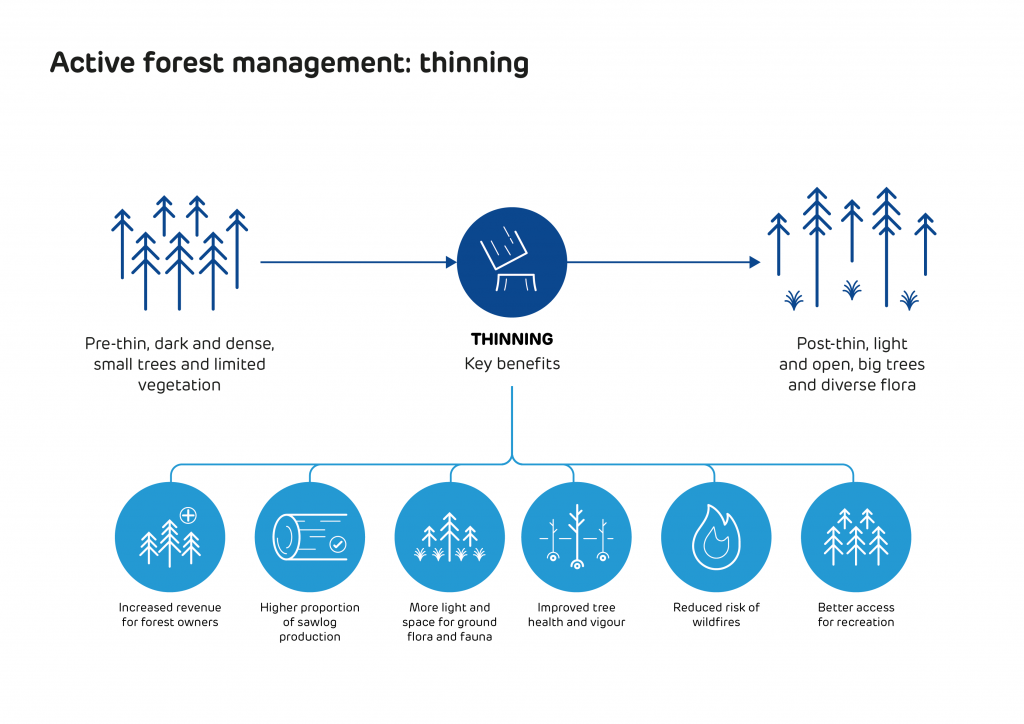

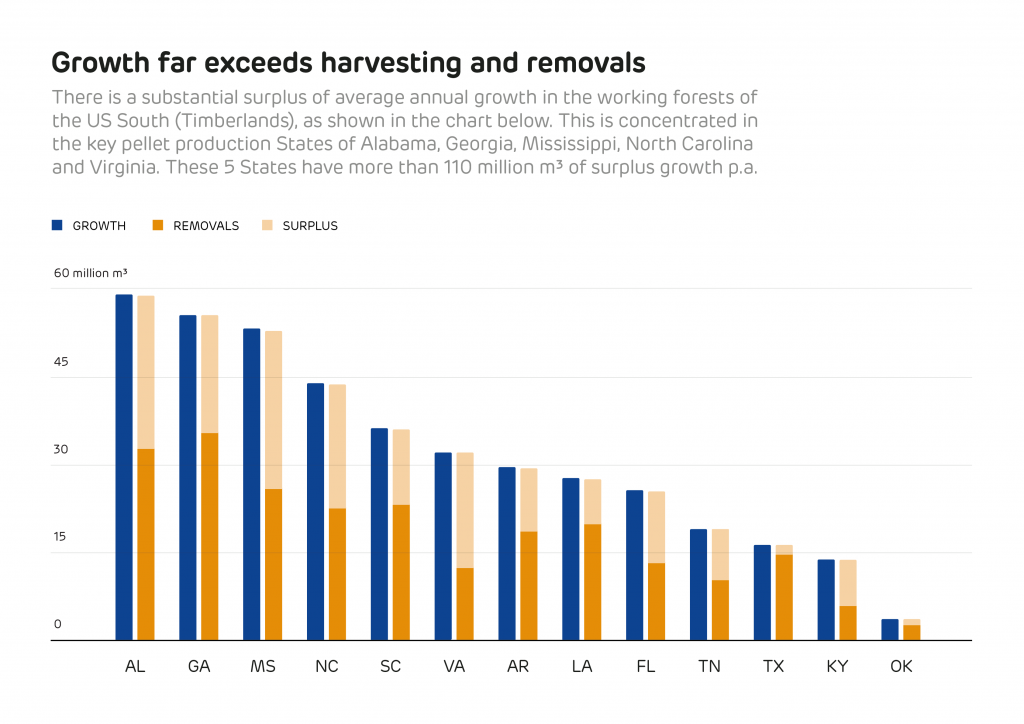

The U.S.’s established forestry commercial industry, with its credible commitment to sustainable management offers ample low-grade wood and wood industry residues to power BECCS. The country’s long-running exploration of CO2 capture and transport, and history of industrial innovations means there are the skills, supply chains, and regulatory environment to undertake ambitious new infrastructure projects.

BECCS is a proven technology and one that can scale up sooner than any other technology. But action is needed now to make these markets that can deliver large scale carbon removals projects a reality.

Action is needed now

For responsible businesses with the desire to go further, faster, or for sectors still developing viable decarbonization routes, carbon removals from BECCS deliver real, verifiable, and permanent progress towards net zero and beyond, to net negative.

It’s encouraging to see the U.S. pass legislation that can facilitate investment into carbon removal technologies and develop the carbon credit market.

However, carbon markets must have standards that are credible both in the business community, and in the environmental and civil society. Collaboration between governments, corporations, and NGOs will be critical to ensure we create systems that can tackle the climate emergency.

We can’t afford to contemplate theoretical net zero futures. Buying and selling high-quality permanent removals is the action we need today. Now is the time to capture the opportunity and be part of the solution together.

Wood construction fell out of favour in the 19th century when materials like steel and concrete, became more readily available. But new developments in timber manufacturing are changing this.

Wood construction fell out of favour in the 19th century when materials like steel and concrete, became more readily available. But new developments in timber manufacturing are changing this.